Friction silk-removing and decolorizing test equipment for textile fabric

A testing equipment and de-threading technology, applied in the direction of testing wear resistance, measuring device, analyzing materials, etc., can solve the problems of inability to realize de-threading and de-coloring detection of fabrics, single-function de-threading or de-coloring detection equipment, etc. Detection process, strong functionality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

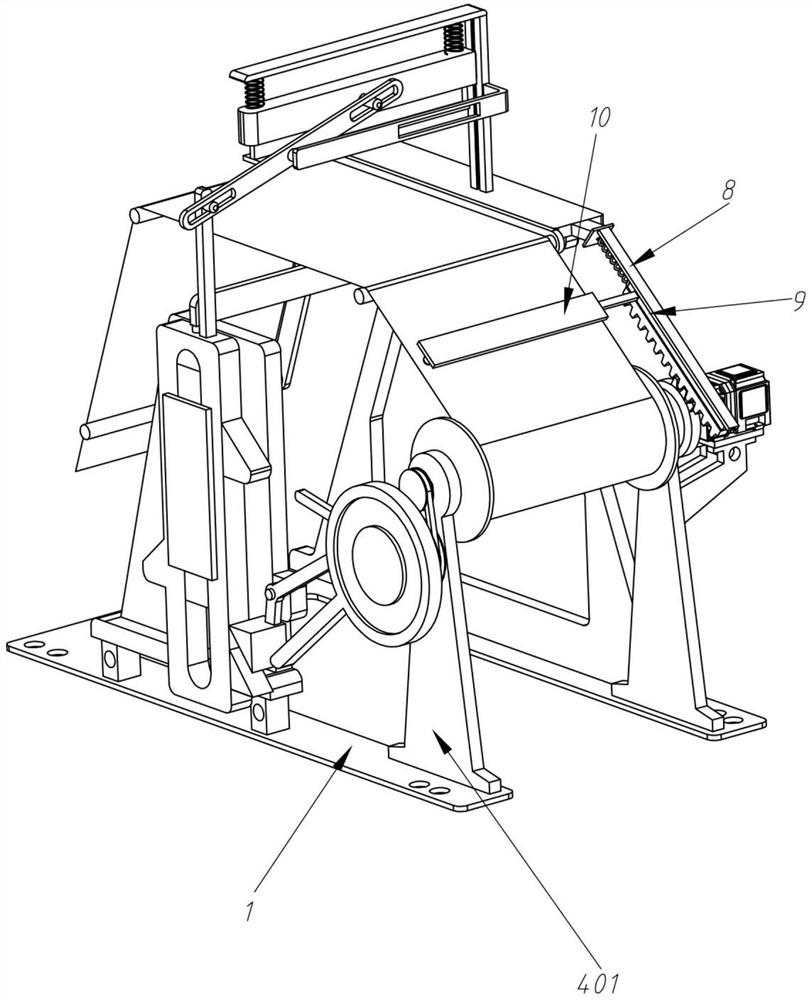

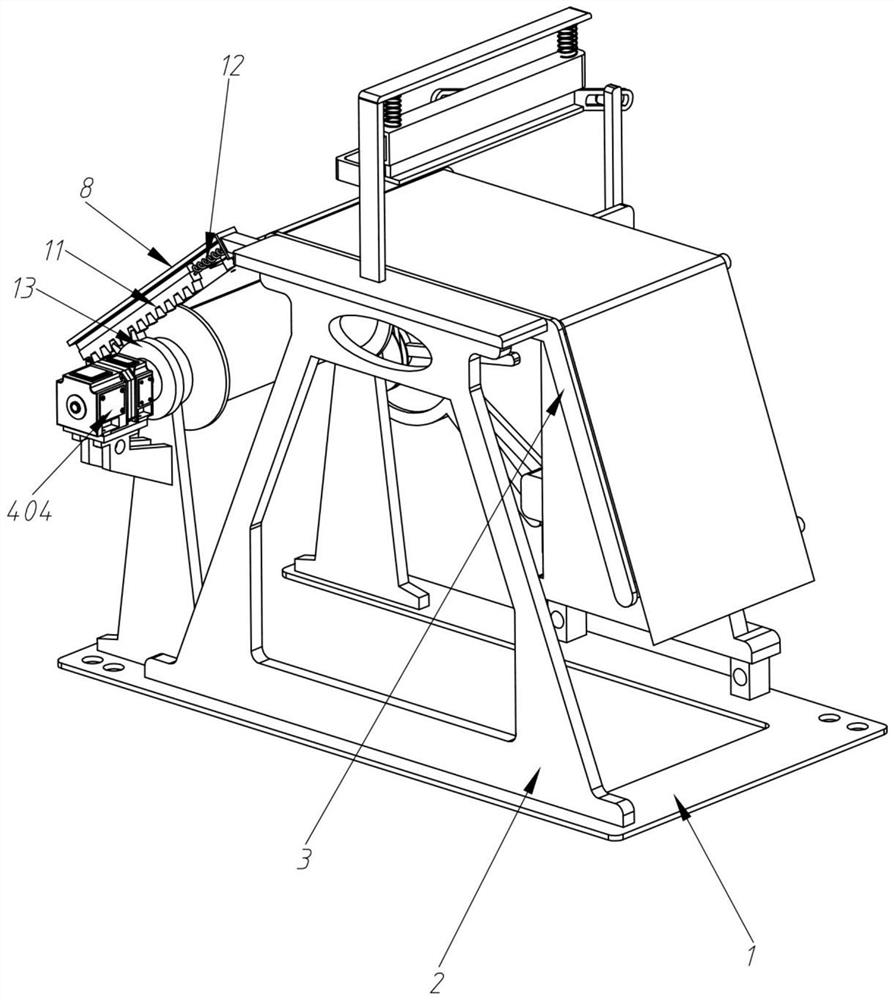

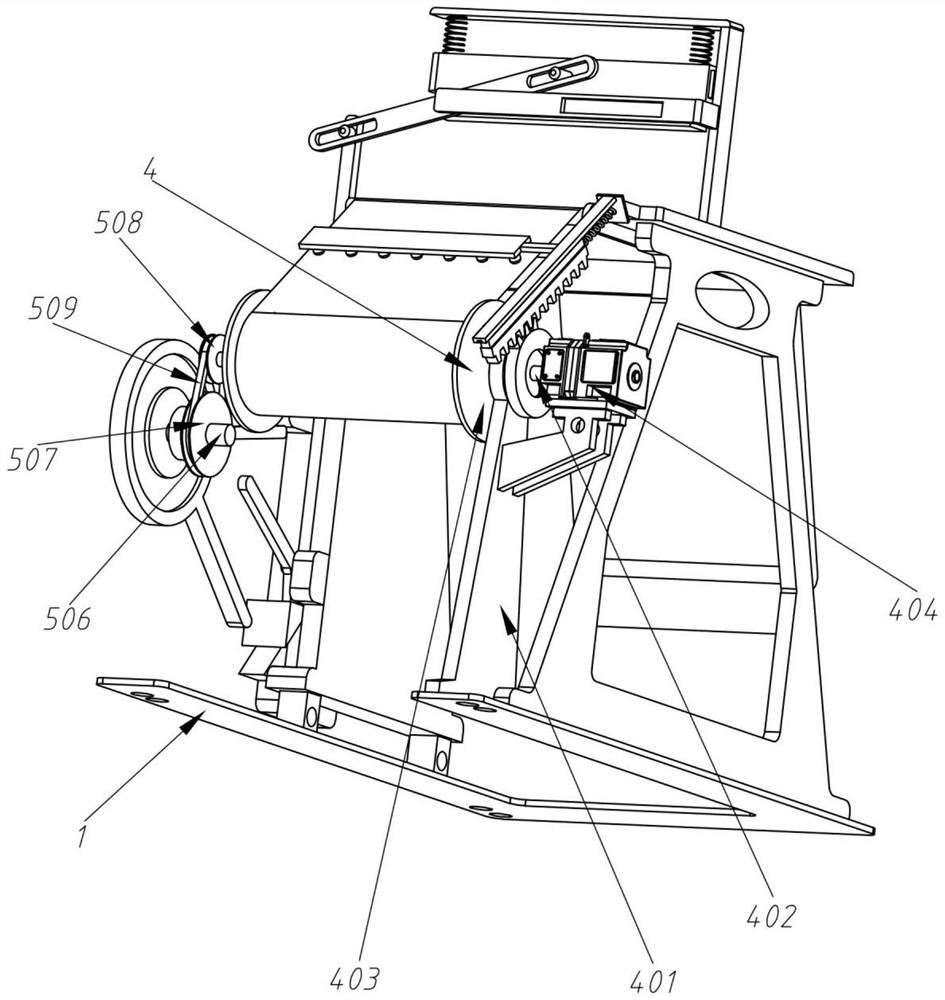

[0022] A kind of test equipment for fabric rubbing and decolorization, such as Figure 1-6 As shown, it includes a U-shaped support plate 1, a support seat 2, a guide frame 3, a cloth winding assembly 4, a cloth pushing assembly 5, and a cloth friction defiling test assembly 7. The support seat 2 is fixedly installed on the U-shaped support plate 1, the guide frame 3 is fixedly installed on the support base 2, the cloth winding assembly 4 is installed on the U-shaped support plate 1 and is close to the support base 2, and the cloth pushing assembly 5 is installed on the U-shaped On the support plate 1 and connected with the cloth winding assembly 4 , the cloth friction stripping test assembly 7 is installed on the upper side of the support base 2 and connected with the cloth pushing assembly 5 .

[0023] Further, the cloth winding assembly 4 used for winding the fabric includes a bearing plate 401, a transmission shaft 402, a winding roller 403 and a servo motor 404, and the U...

Embodiment 2

[0029] On the basis of Embodiment 1, such as Figure 1-2 As shown, it also includes a slide rail 8, a slide bar 9, a friction colorimetric plate 10, a rack 11, a third compression spring 12 and a sector gear 13, and the slide rail 8 is fixedly installed on one end of the support base 2 and is connected with the guide The frame 3 is close, the sliding bar 9 is slidably installed on the slide rail 8, the friction colorimetric plate 10 is fixedly installed on the sliding bar 9 and the material of the frictional colorimetric plate 10 is white rubber, and the frictional colorimetric plate 10 is made of white rubber. 10 is used to move left and right on the upper surface of the fabric for decolorization detection. The rack 11 is fixedly installed on the bottom side of the slide bar 9, and a third rack is installed between one end of the slide bar 9 and one side of the slide rail 8. The spring 12 is compressed, the sector gear 13 is fixedly installed on the transmission shaft 402 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com