Power battery life prediction method and system

A power battery and life-span technology, applied in the field of vehicle engineering, can solve problems such as poor adaptability, unsatisfactory prediction accuracy of power battery life, long test time, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

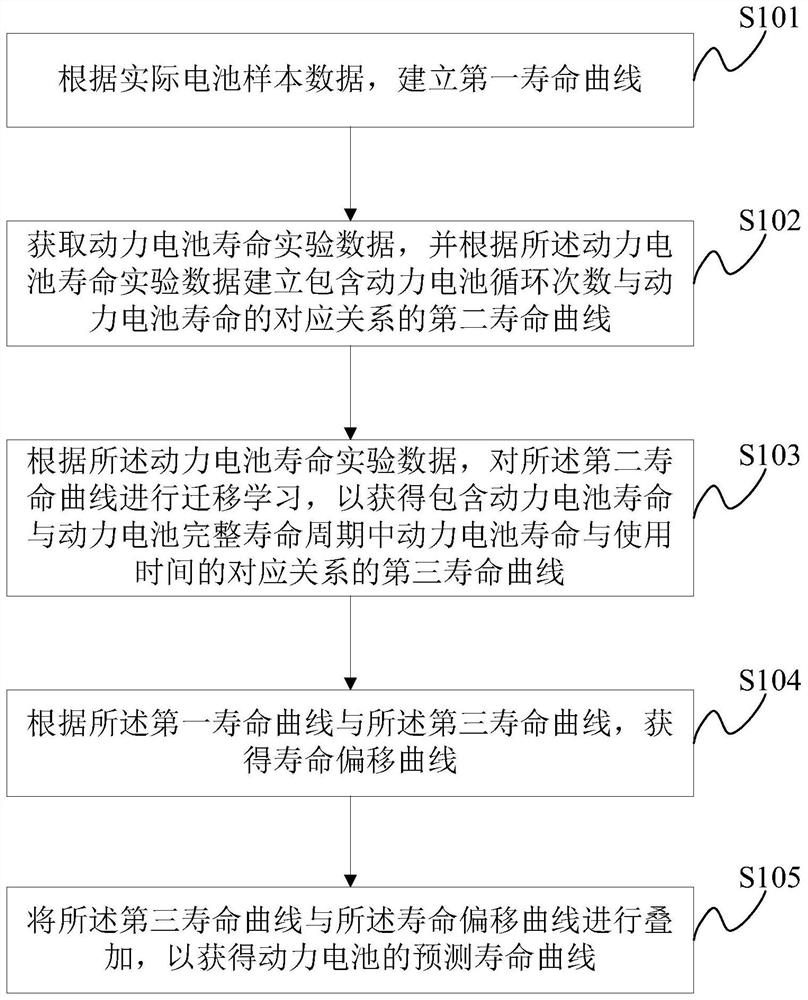

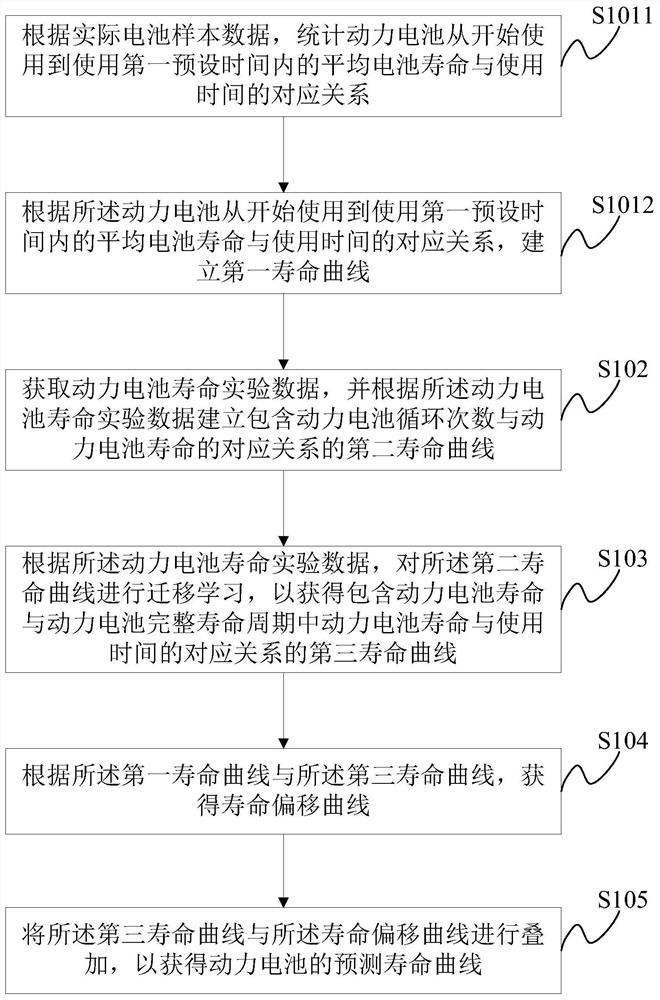

Method used

Image

Examples

Embodiment Construction

[0055] As described in the background, there are various problems in the prior art methods for power battery life prediction.

[0056] Among them, the electrochemical analysis method refers to the description of the dynamic parameters of the battery, the mass transfer process, the thermodynamic characteristic parameters, the mechanical, thermal, and electrical characteristics of the battery from the perspective of the internal physical and chemical processes of the battery, and the analysis of the operating mechanism of the battery. And establish the degradation model of the battery;

[0057] The safety method is to conduct various accelerated tests on the battery during the entire life cycle of the battery, such as temperature acceleration, discharge rate, discharge depth acceleration, etc., that is, to regularly test the battery capacity according to a certain discharge rate (manufacturer's regulations or industry standards) , to estimate the degradation model of battery cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com