Three-dimensional head-mounted microscope

A head-mounted, microscope technology, used in microscopes, optics, instruments, etc., can solve the problems of complex shape of optical components, large loss, blocking imaging area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

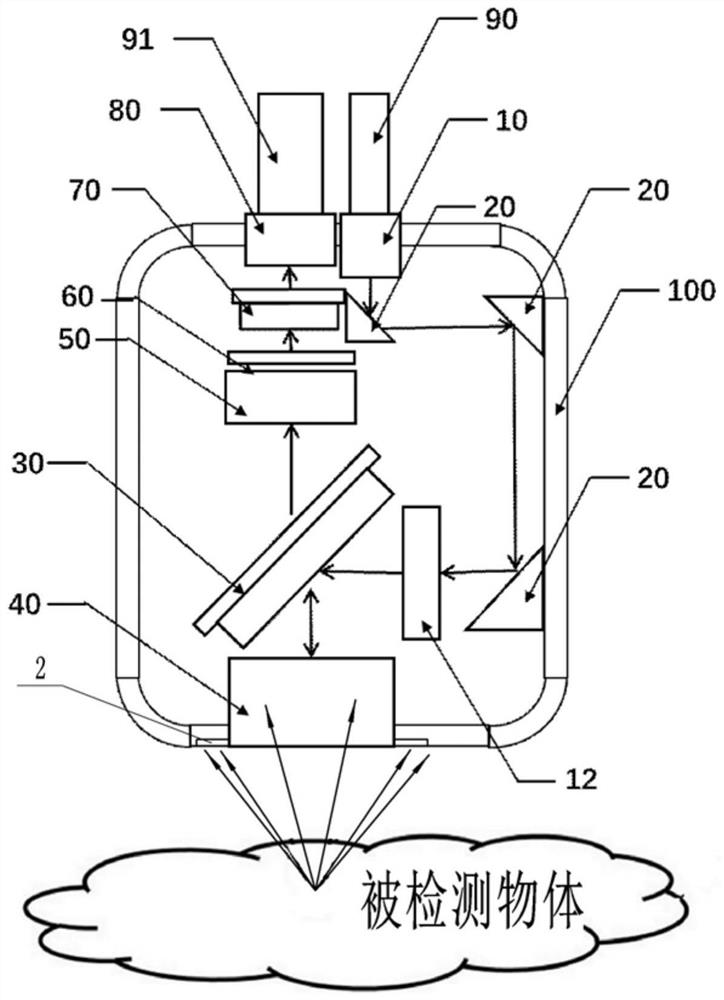

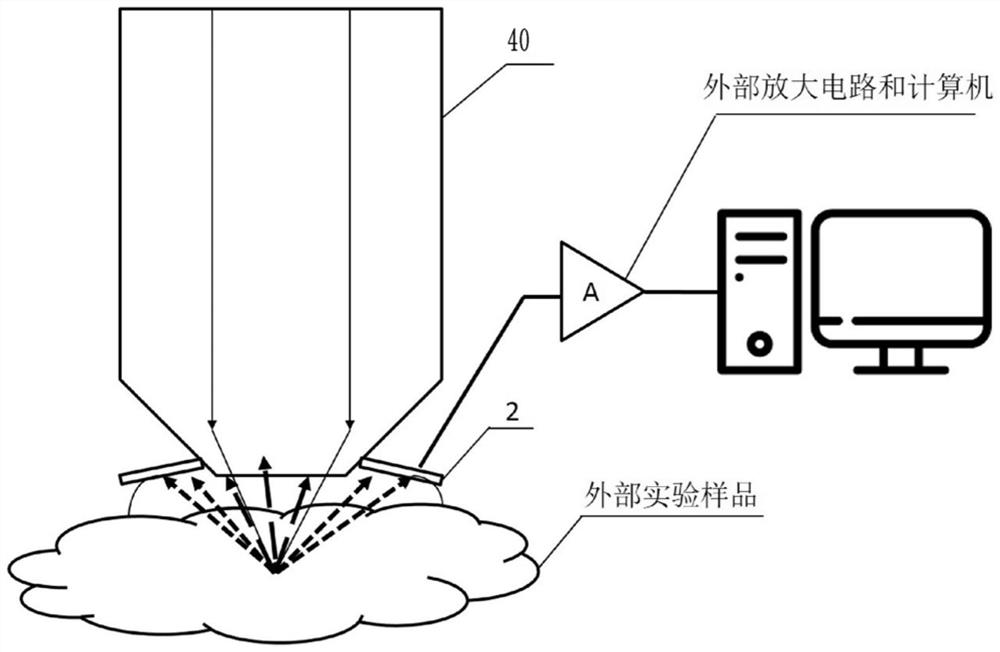

[0031] Basic as attached figure 1 Shown: a three-dimensional head-mounted microscope, including a square housing 100, the housing 100 is a sealed structure made of a high molecular polymer material, and a collimating lens 10, a cylindrical lens 12, a reflector 20, and a dichroic lens are installed in the housing 100 Chromatic mirror scanner 30, objective lens 40, focusing lens 50, wave plate 60, vertical dichroic mirror scanner 70 and collecting lens 80, specifically, for the installation method, it can be bonded, clamped, bonded or welded . combine Figure 5 with Image 6 As shown, the dichroic mirror scanner 30 in this embodiment includes 33 dichroic mirrors and a microelectromechanical driver 22 that does not affect the transmission of nonlinear optical signals. The 33 dichroic mirrors are covered on the microelectromechanical driver 22. The MEMS driver 22 can drive the dichroic mirror 33 to change the angle. Object lens 40 is an aspherical lens in the present embodimen...

Embodiment 2

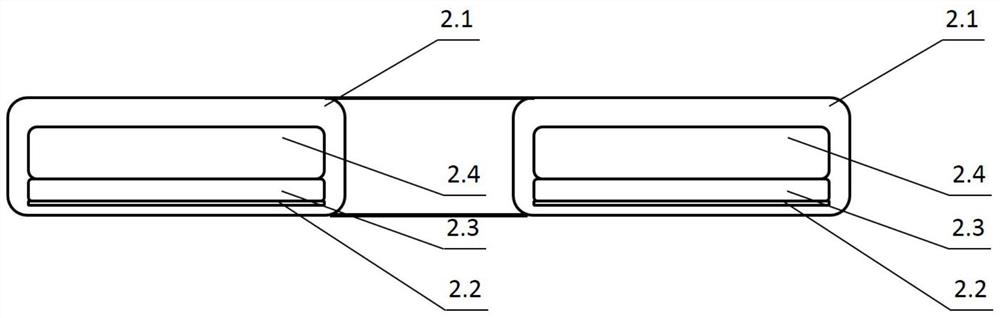

[0049] In the present embodiment, the photosensitive unit 2.3 of the photodetector 2 is formed into an annular array by a plurality of ordinary size avalanche diodes (Avalanche Photo Diode, LAAPD). Chips of common-sized avalanche diodes are used to receive fluorescent photons that cannot be picked up by microscope objectives.

Embodiment 3

[0051] The photosensitive unit 2.3 of the photodetector 2 among the present embodiment is formed ring array by two-dimensional pixel photosensor, as CCD (photoelectric coupling device) device, CMOS (metal semiconductor oxide) device, FPA (focal plane array) device, PMT (photomultiplier tube) device, single photon counting device or hybrid device based on any of the above multiple photoelectric conversion principles, such as Hamamatsu's hybrid photodetector (HPD), the central hole or transparent material is used to pass through the microscope objective An annular array of two-dimensional pixel photosensors is used to receive the fluorescent photons that cannot be received by the microscope objective.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com