Loss-reduction and loss-prevention elastic control soil-pressing mechanism for potato harvester

An elastic control and harvester technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of increasing the rate of open potato, falling potato pieces to the surface, crushing and crushing damage, etc. Achieve the effect of reducing labor intensity, ensuring harvest quality, and avoiding crushing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

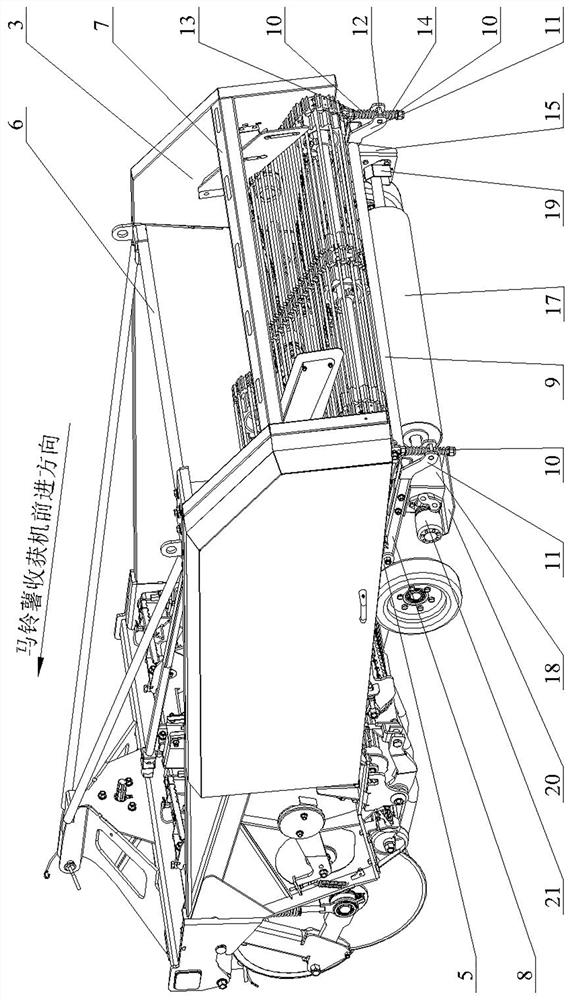

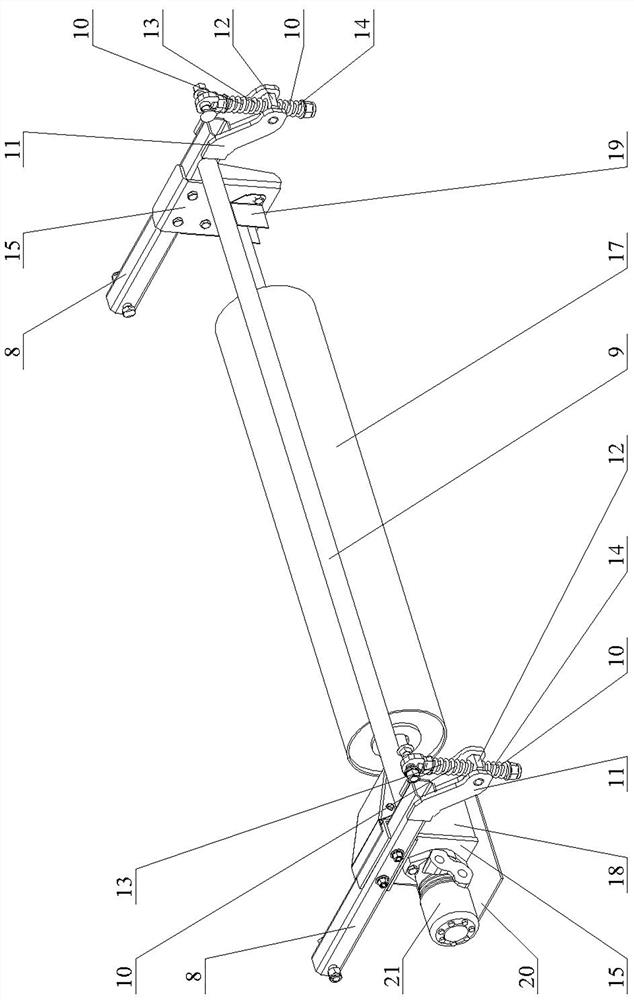

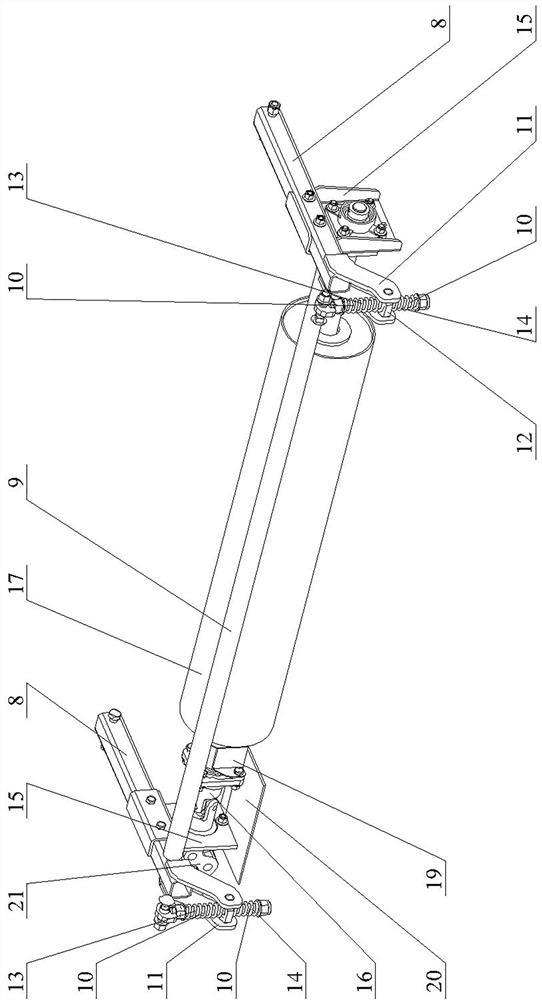

[0015] 1. Column 2. Reinforcing rod 3, Vertical plate 4, connecting rod 5, lug Ⅰ 6, crossbar Ⅰ 7, crossbar Ⅱ 8, support arm 9, crossbar Ⅲ 10, adjusting screw 11, lug Ⅱ 12, Spring seat plate 13, compression spring I 14, compression spring Ⅱ 15, mounting plate 16, coupling 17, pressure roller 18, 5-face guard 19, U-shaped guard 20, retaining plate 21, hydraulic motor.

[0016] in Figure 1~Figure 4 In the illustrated embodiment: one end of the two reinforcing rods 2 in the shape of straight rods of the frame are respectively fixedly connected to the hollow column 1 which is in the shape of straight rods, and the ends of the two reinforcing rods 2 away from the vertical column 1 are connected Together, the crossbar includes a crossbar I6 and a crossbar Ⅱ7. One end of the two crossbars I6 is respectively fixedly connected to both ends of the column 1 of the combination of one column 1 and two reinforcement rods 2, and the two crossbars The rod I6 is perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com