Technology method of sealed scented jasmine tea

A process method and technology for jasmine flowers, applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problems of reducing the concentration of aroma substances on the surface of tea, enhance the ability to absorb and retain aroma, reduce the scenting temperature, avoid the desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

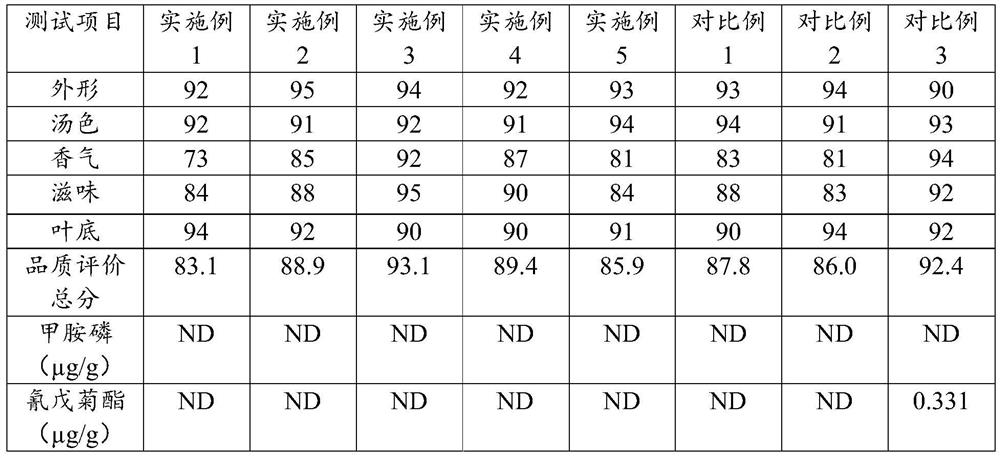

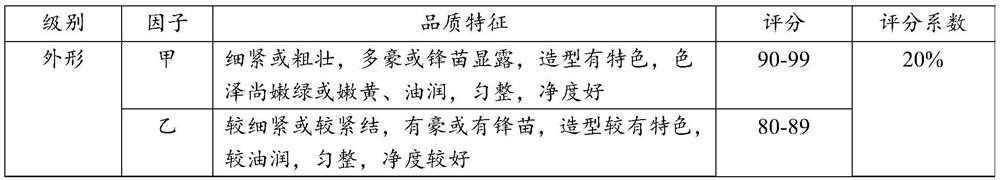

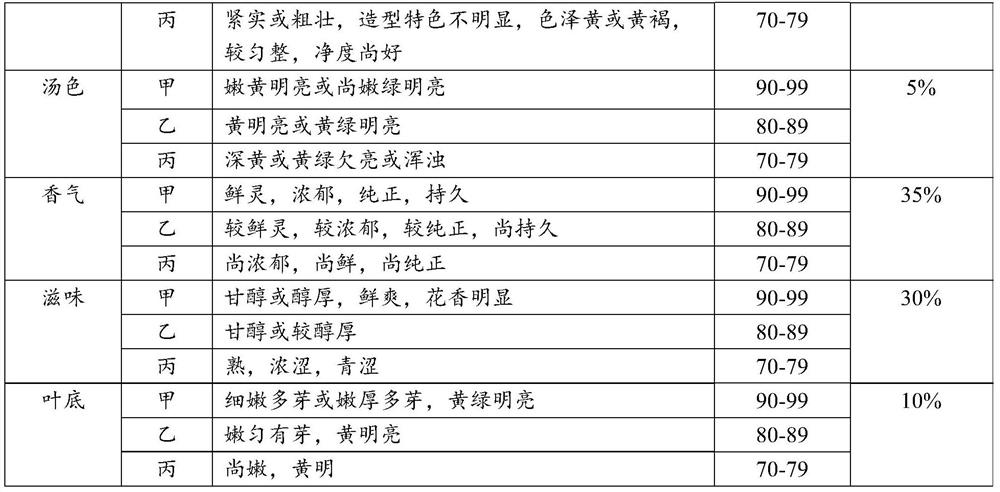

Examples

Embodiment 1

[0036] A kind of technological method of isolated scenting jasmine tea, comprises the following steps:

[0037] (1) Tea base processing and flower processing:

[0038] Tea dhool treatment: Spray 5 parts of 1% porous starch solution onto the surface of 100 parts of tea dhool, then dry at 60°C, control the water content of tea dhool to 15%, and wait for the tea dhool to cool naturally to room temperature.

[0039] Flower treatment: choose jasmine flowers as spices for scenting jasmine tea. After entering the factory, spread them thinly to dissipate heat in time, with a thickness of 12-15cm. Scenting can be carried out when the opening degree is greater than or equal to 60%. Fresh flower treatment method is commonly used in prior art.

[0040] Because the biggest difficulty in isolating scented flowers is the lack of fragrance, therefore, in the scenting method, the proportioning and quality of scented flowers are also one of the aspects that affect the problem. It is advisabl...

Embodiment 2

[0049] This embodiment is a process for scenting jasmine tea in isolation. The difference between the specific steps and Embodiment 1 of the present invention is that the water content of the tea base is 10%. Adopt the processing method of present embodiment, prepare a kind of jasmine tea.

Embodiment 3

[0051] This embodiment is a process for isolated scenting jasmine tea, the difference between the specific steps and the embodiment 1 of the present invention is that the water content of the tea base is 15%. Adopt the processing method of present embodiment, prepare a kind of jasmine tea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com