A food processor with good cleaning effect

A food processing machine and cleaning effect technology, which is applied in the field of food processing, can solve the problems of wasting electric energy, poor lifting effect of the pulverizer, and great influence on cleaning and crushing effects, and achieve the effect of saving cleaning water and reducing attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

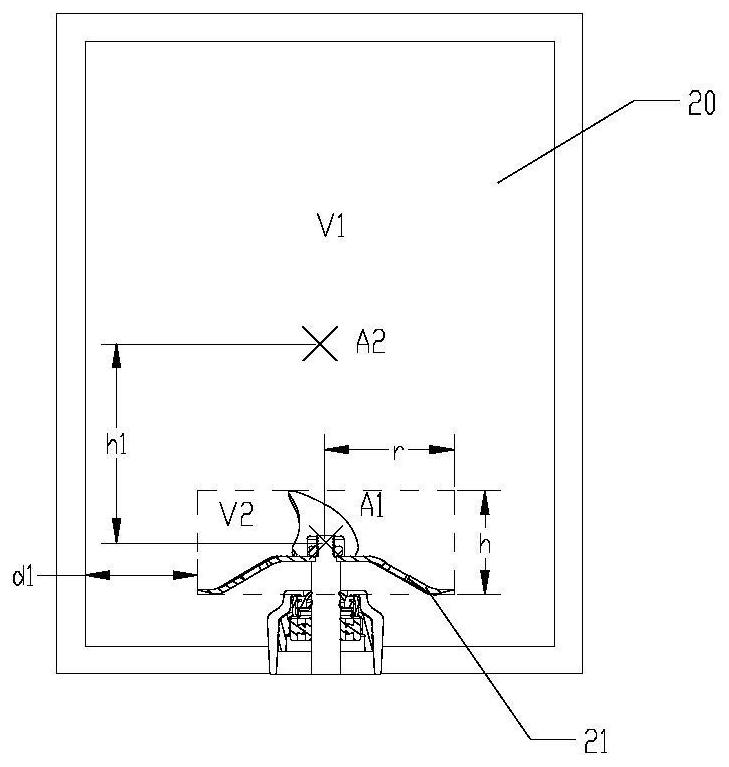

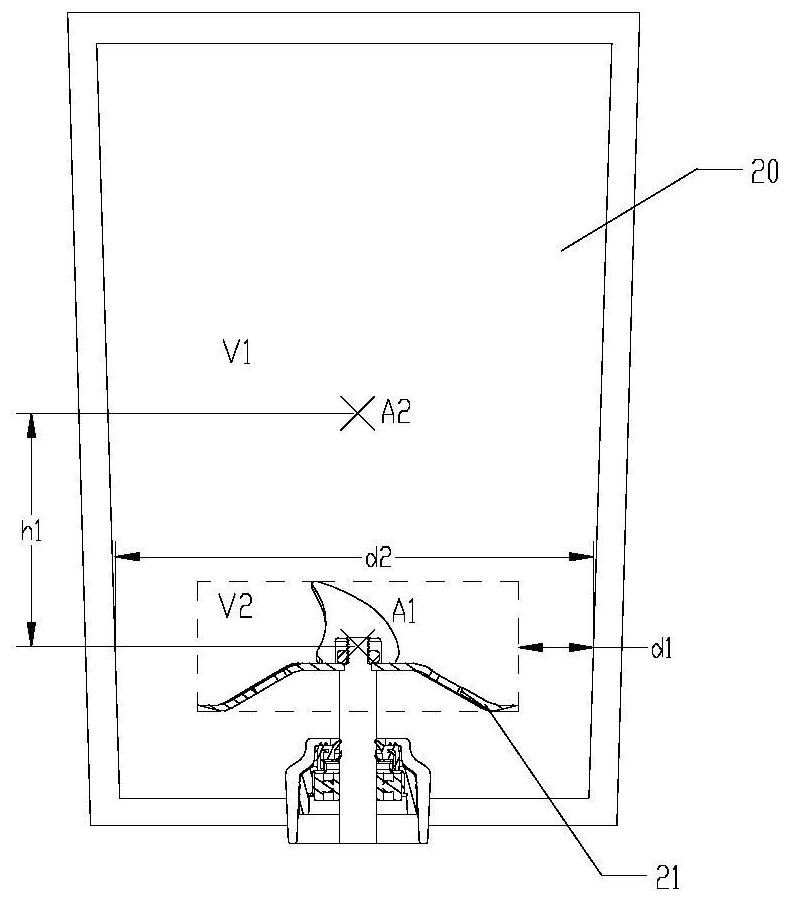

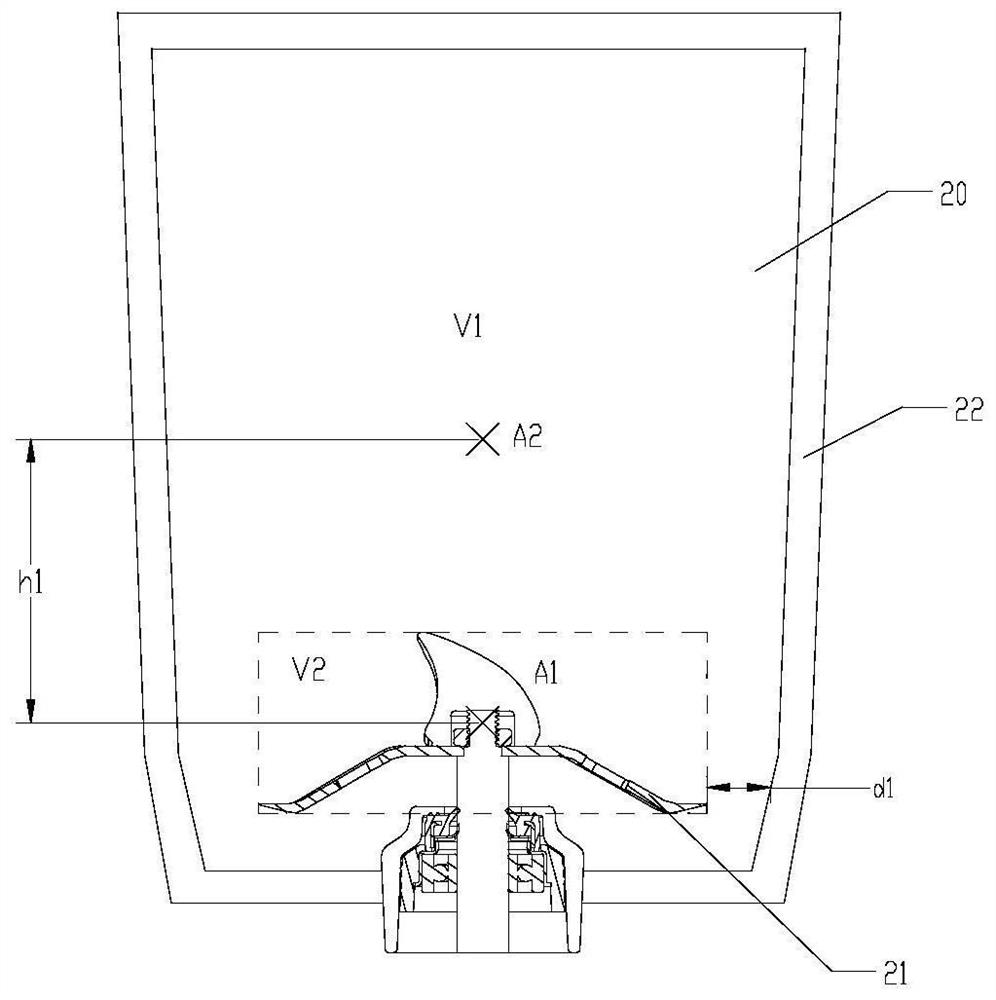

[0037] The invention provides a food processing machine with good cleaning effect, such as figure 1 As shown, the food processing machine includes a crushing chamber 20, the bottom of the crushing chamber 20 is provided with a cleaning knife 21, the volume of the crushing chamber 20 is V1, and the cleaning knife 21 is a four-leaf knife that is symmetrically distributed in the center, wherein the two oppositely arranged knives The leaf part is bent upwards to form the upper blade, and the other two blades are partially bent downward to form the lower blade. The tip of the upper blade is the highest point of the cleaning knife, and the tip of the lower blade is the lowest point of the cleaning knife 21. point, the height of the orthographic projection of the tip of the upper blade and the tip of the lower blade on the axial direction of the crushing chamber 20 is h, the distance between the tip of the upper blade and the tip of the lower blade from the axis of the knife on the ho...

Embodiment 2

[0064] The difference between this embodiment and the first embodiment is that the main machine is equipped with a water tank to automatically feed water into the crushing chamber.

[0065] Such as Figure 4 As shown, the food processing machine includes a main machine 10, a motor 11 is installed in the main machine 10, and a stirring cup is installed above the motor 11. The stirring cup includes a cup body and a cup cover, and the cup body and cup cover are enclosed to form a crushing chamber 20. The bottom of the stirring cup is provided with The cleaning knife 21 is fixed to the output shaft of the motor 11, the mixing cup is provided with a water inlet 50, and the side of the main machine 10 is provided with a water tank 30, and the water tank 30 is connected with the water inlet 50 of the mixing cup through a water pump and a pipeline to realize automatic water intake , The stirring cup is provided with a drain pipe 60, and the outlet of the drain pipe 60 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com