Fast-assembly connecting structure and nut-free hammering fixing method

A connection structure and quick installation technology, applied in the direction of connection components, pins, mechanical equipment, etc., can solve the problems of unstable installation and cumbersome installation process, and achieve the effects of convenient operation, labor saving, convenient installation, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

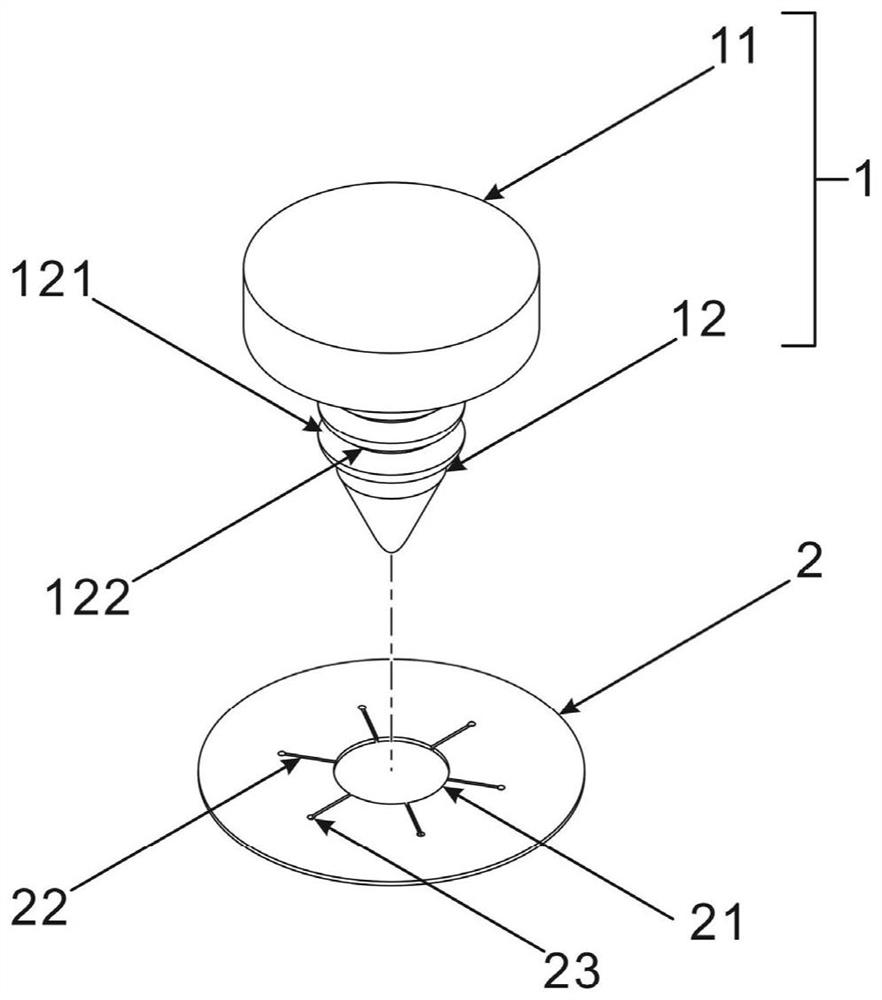

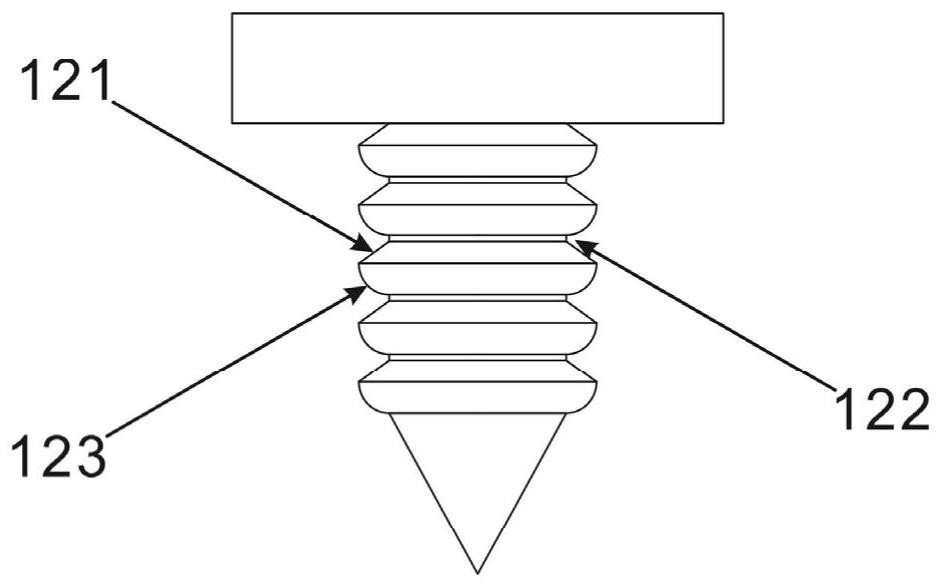

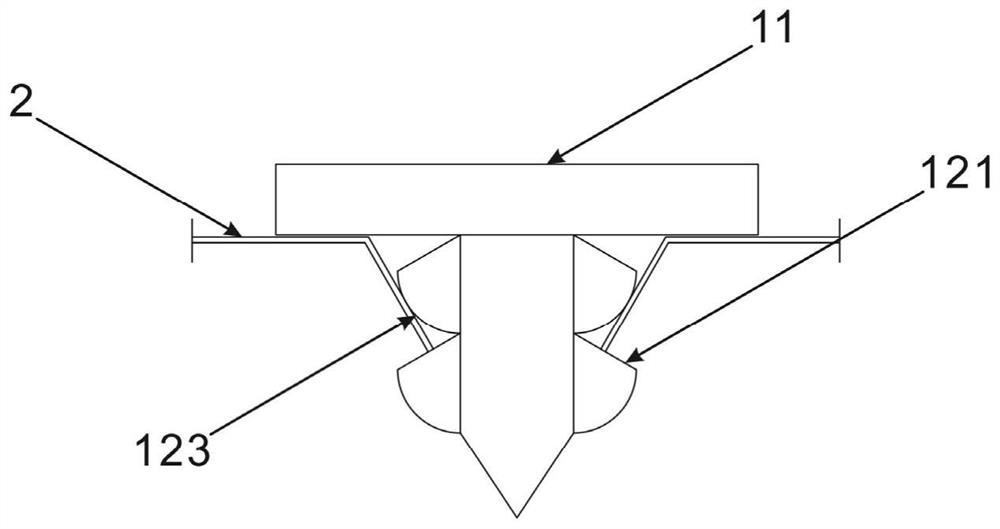

[0040] The invention provides a quick-fit connection structure, such as figure 1 As shown, the quick-fit connection structure includes a connecting piece 1 and a metal sheet 2, the metal sheet 2 is arranged in various shapes, and the metal sheet 2 is set as a thin iron sheet, wherein: the connecting piece 1 includes a limiting part 11 and The column part 12 arranged on the limiting part 11, the diameter of the limiting part 11 is greater than the diameter of the column part 12, the column part 12 is provided with an annular protrusion, and an insertion groove 122 is formed between adjacent annular protrusions, and the insertion The side of the groove 122 away from the stopper 11 is inclined to form the abutment surface 121; the metal sheet 2 is provided with a mounting hole 21, and when the connector 1 is connected to the metal sheet 2, the post 12 is inserted into the mounting hole 21 , the inner edge of the installation hole 21 is bent and inserted into the insertion groove ...

Embodiment 2

[0055] Embodiment 2 is based on Embodiment 1: the present invention provides a kind of nutless vertical fixation method, comprising the following steps:

[0056] (i) Make holes for the objects to be connected (this step is not required for the objects to be connected that already have holes in them);

[0057] (ii) adopt punching machine to press mounting hole 21, straight seam 22 and anti-crack hole 23 to metal sheet 2, the two ends of straight seam 22 are connected with installation hole 21 and anti-crack hole 23 respectively, the quantity of straight seam 22 and anti-crack hole 23 The number is the same, and all the straight seams 22 are arranged circumferentially relative to the mounting holes 21;

[0058] (iii) Align the post 12 of the connector 1 with the opening and the installation hole 21, and hammer the stopper 11 of the connector 1, so that the post 12 passes through the opening and the installation hole 21 in sequence, During the hammering process, the inner edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com