Automatic welding slag scraping device, automatic welding slag scraping method and solar water heater

A welding slag and automatic technology, which is applied in the direction of solar collectors, solar collector components, solar thermal energy, etc., can solve the problems of effect differences and achieve the effect of high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

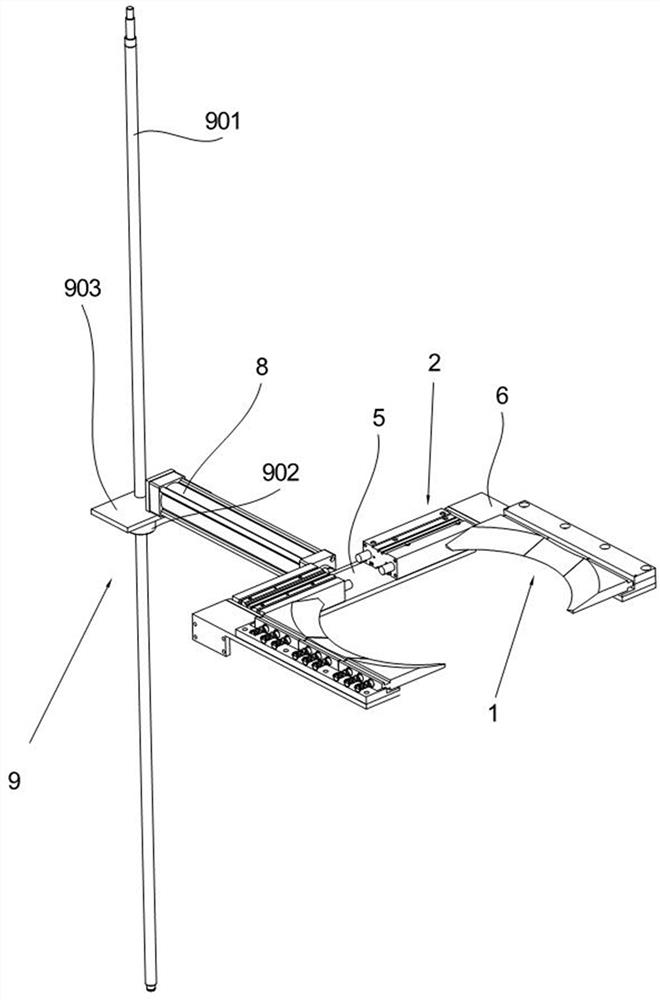

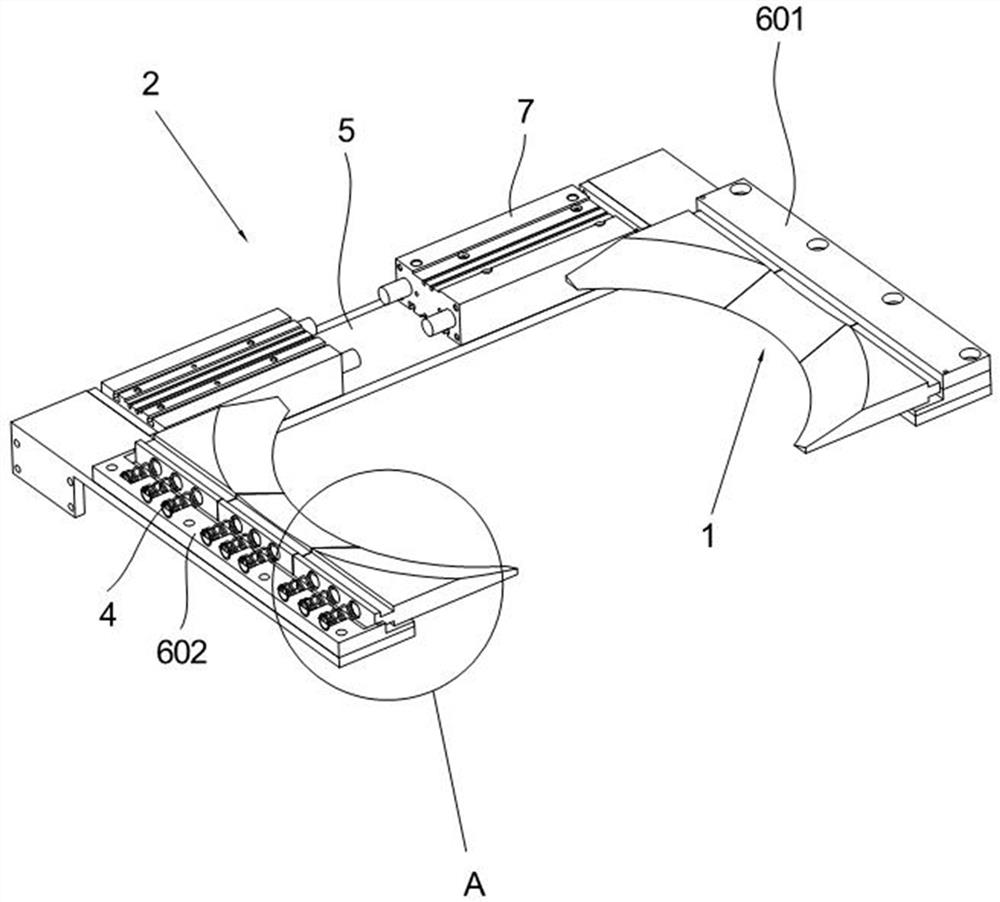

[0037] An automatic welding slag scraping device, such as figure 1 and 2 As shown, it includes at least one pair of scrapers 1 and a fixed seat 2 for fixing the scraper 1. A pair of scrapers surround a cavity for the enamel liner to pass through. An elastic structure is provided between the scraper and the fixed seat. The scraper moves with the elastic structure to adjust the size of the cavity.

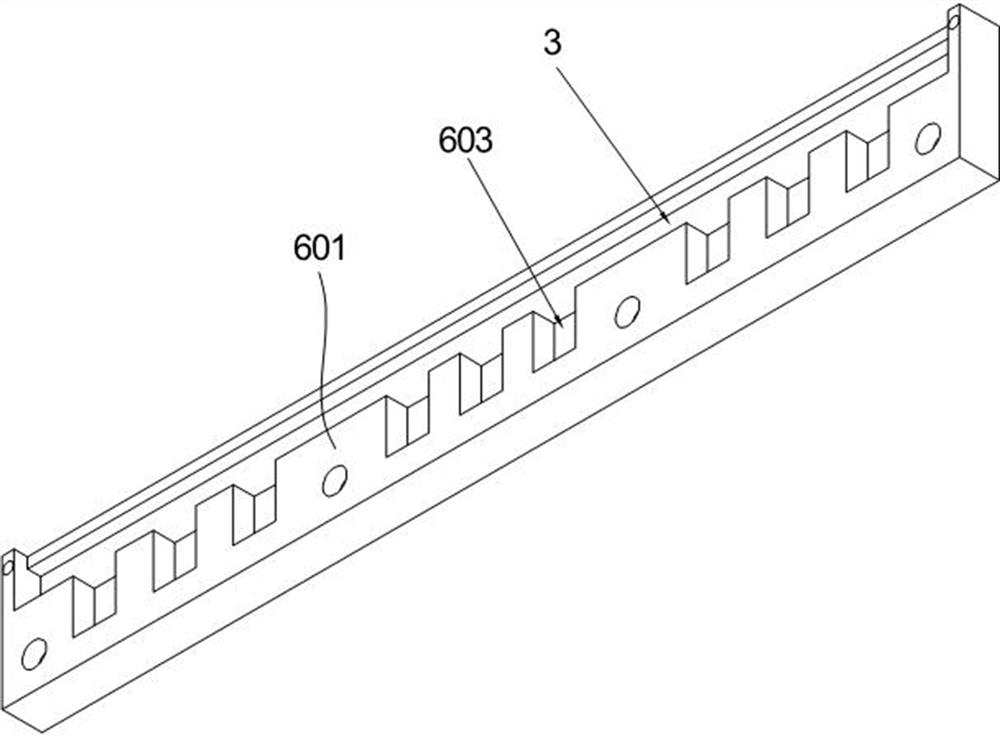

[0038] Preferably, the elastic structure includes an insertion slot, an insertion block slidingly arranged in the insertion slot, and an elastic member for adjusting the position of the insertion block in the insertion slot, and the insertion slot is set On one of the scraper and the fixing seat, the plug block is arranged on the other of the scraper and the fixing seat. In this embodiment, an insertion slot 3 is provided in the fixed seat 2, and the end of the scraper 1 is provided with an insertion block 101 slidably connected in the insertion slot 3, and the width of the inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com