An automatic machining system for manufacturing stainless steel valves

An automatic machine and processing system technology, applied in manufacturing tools, metal processing equipment, grinding racks, etc., can solve problems such as valve shaking, valve fixing is not stable enough, and processing cost increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

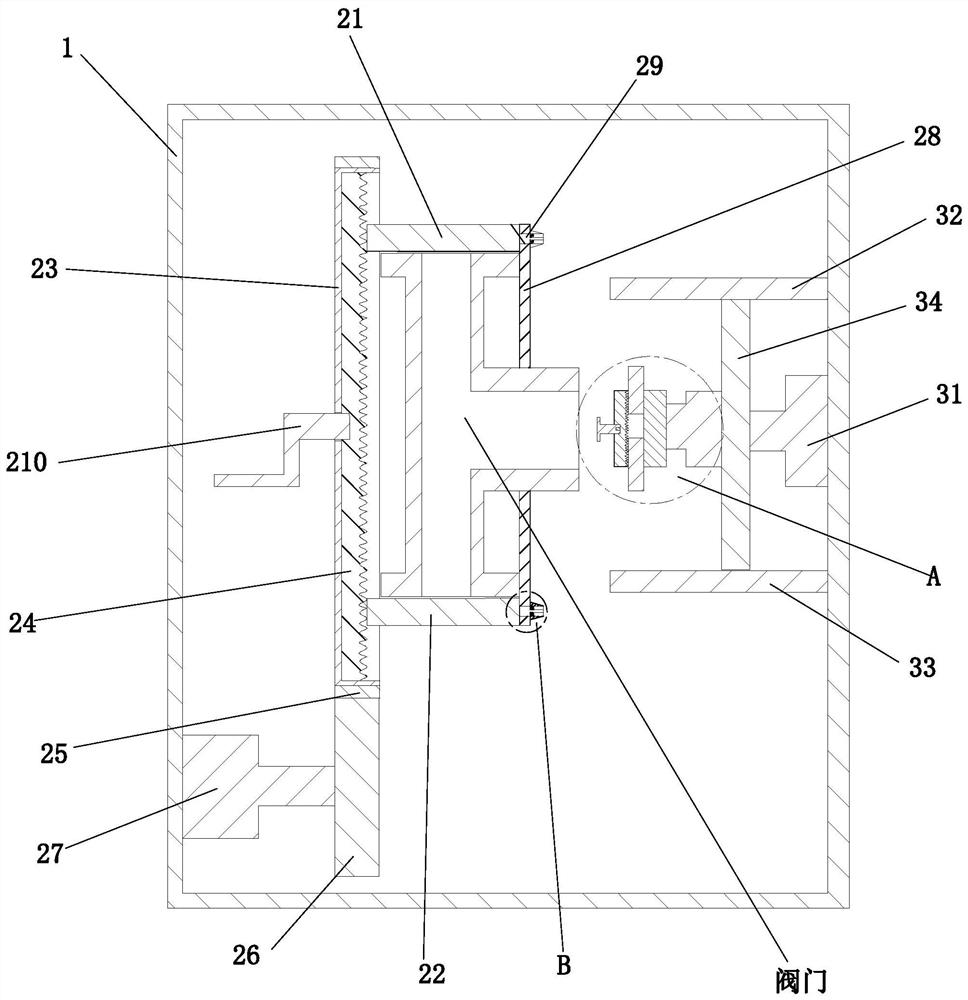

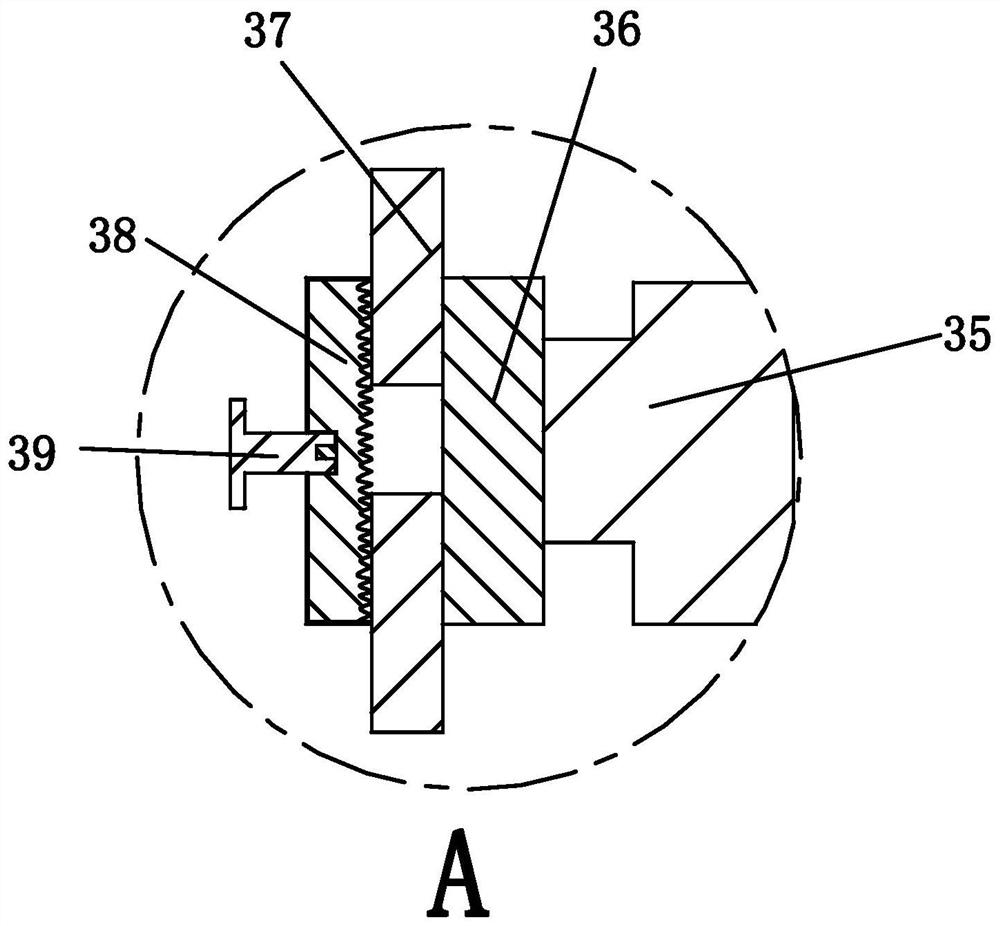

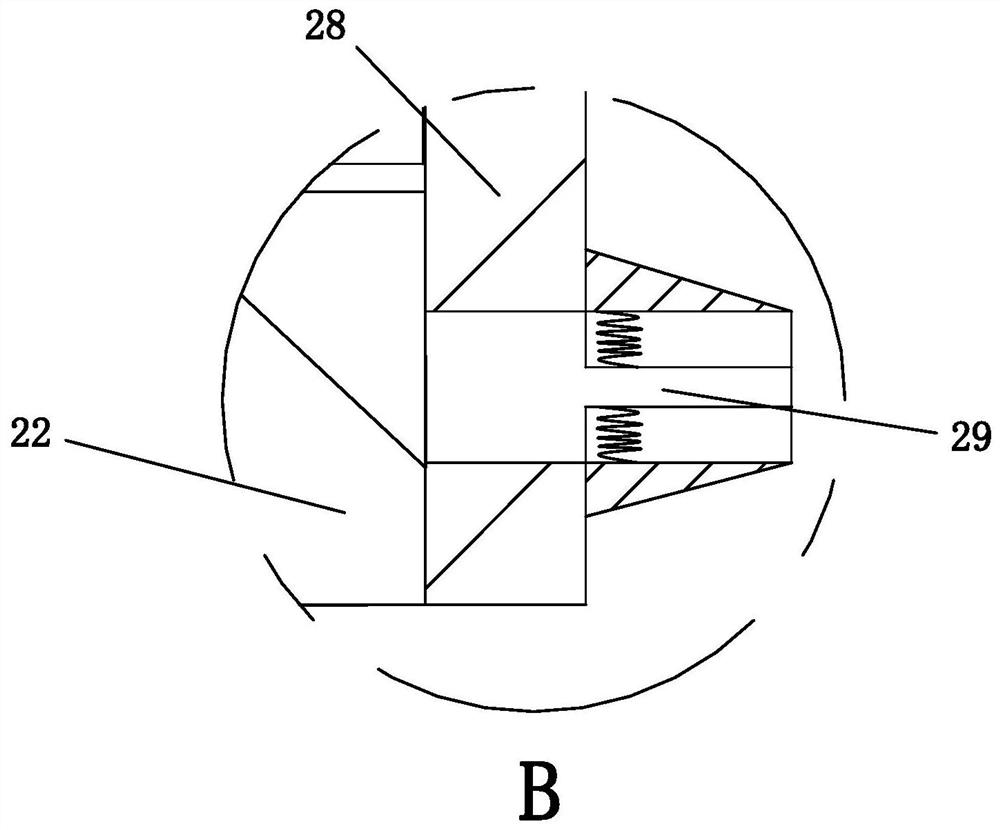

[0029] Such as Figure 1 to Figure 6 As shown, an automatic machining system for manufacturing stainless steel valves includes a return frame 1, a clamping device 2 and a grinding device 3, the clamping device 2 is installed on the left inner wall of the return frame 1, and the grinding device 3 is installed On the right inner wall of the clip-on frame 1; wherein:

[0030] The clamping device 2 includes an upper clamping plate 21, a lower clamping plate 22, a connecting plate 23, a clamping threaded plate 24, a driving gear 26, a reversing motor 27, a fixing plate 28, a block 29 and a clamping handle 210 , the reversing motor 27 is installed on the inner wall of the lower left side of the return frame 1 through the motor base, the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com