Printing apparatus

A technology of printing device and printing department, which is applied in the direction of printing device, printing, typewriter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

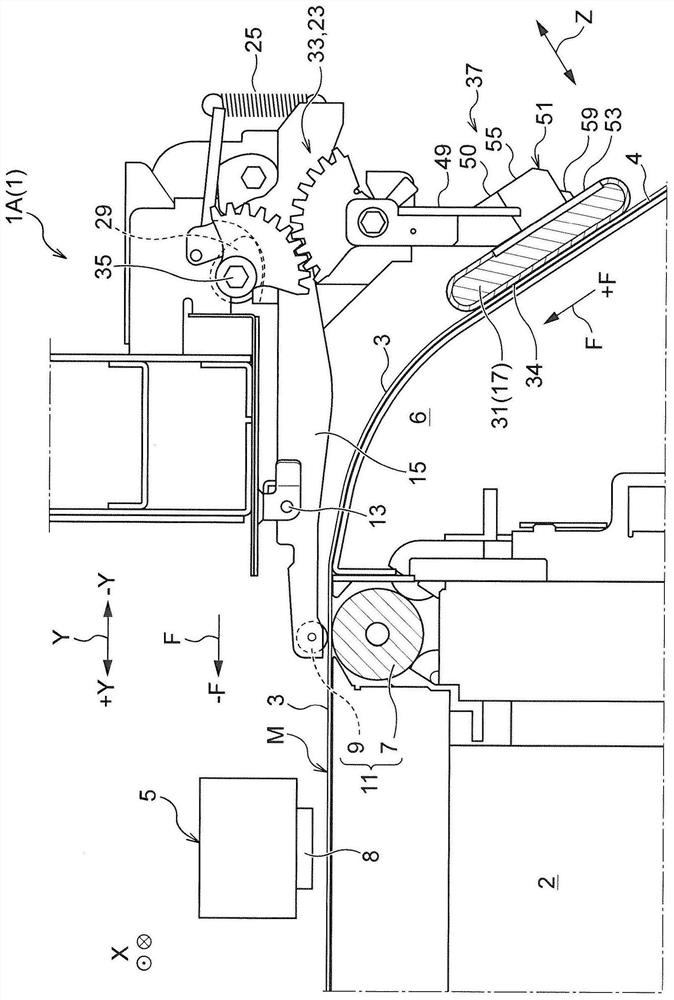

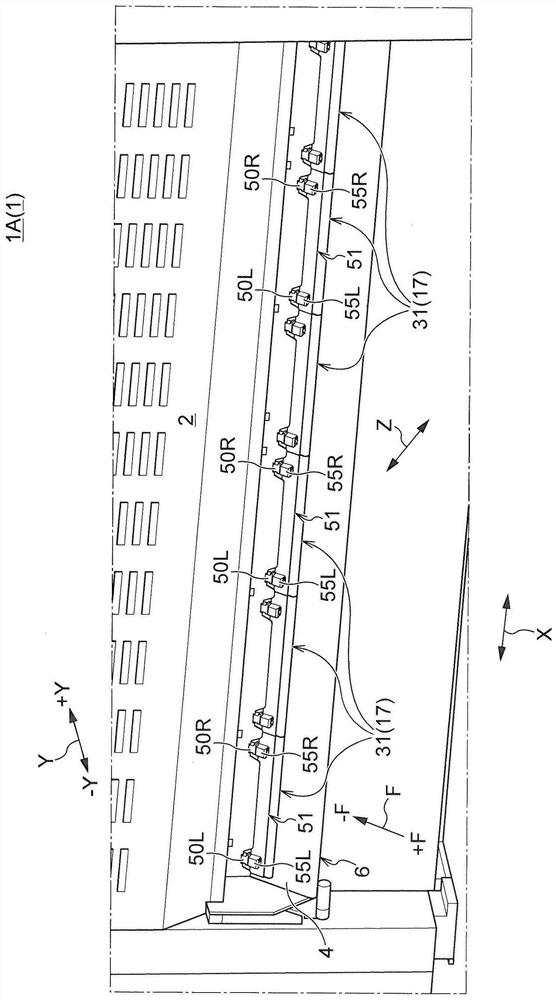

[0042] (1) Outline of the overall structure of the printing device (refer to figure 1 as well as figure 2 )

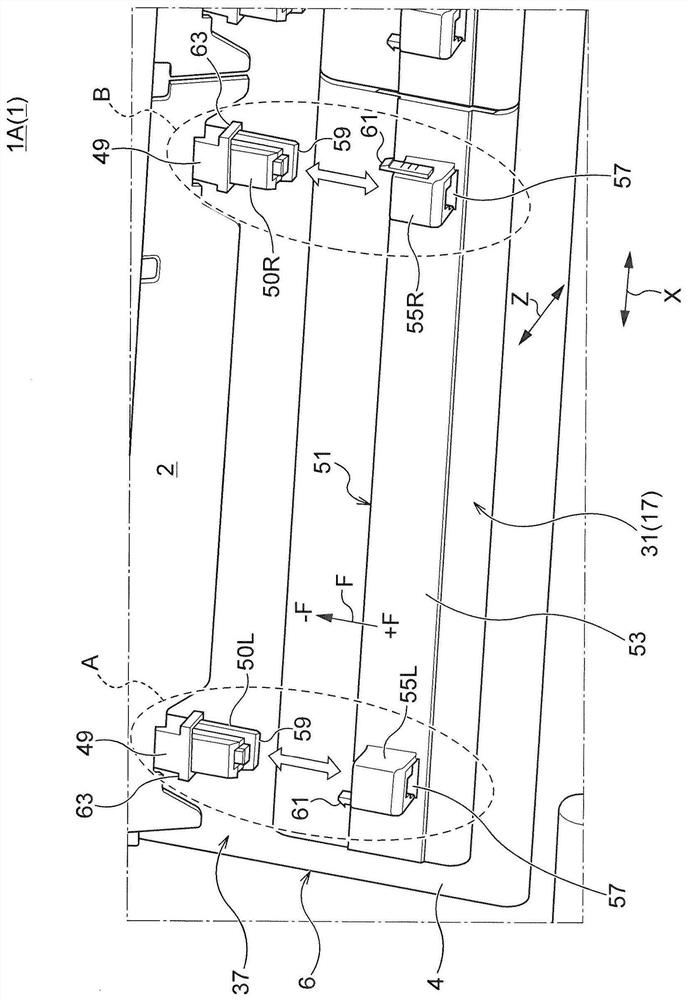

[0043] The printing device 1 of the present invention has: a printing unit 5, which prints on the printing surface 3 of the medium M; a transport unit 11, which transports the medium M along the transport direction F; a medium support surface 4, which is located in the transport direction F relative to the printing unit 5 Upstream + F, supports the medium M; the pretreatment unit 17 preprocesses the medium M supported by the medium support surface 4; and the assembly unit 50 is located opposite to the medium support surface 4, and the pretreatment unit 17 is detachable Attached to the mounting part 50 .

[0044] Furthermore, the mounting unit 50 has a position limiting mechanism 37 that limits the position of the preprocessing unit 17 relative to the medium supporting surface 4 when the preprocessing unit 17 is mounted.

[0045] The illustrated printing device 1A i...

Embodiment approach 2

[0081] Implementation mode two (refer to Figure 6 )

[0082] Next, based on Figure 6 The structure, function, and effect of the printing apparatus 1C according to the second embodiment of the present invention, which is partially different from the structure of the embodiment, will be described.

[0083] The printing device 1C according to the second embodiment is a so-called printing and dyeing device that performs printing on the fabric N, and performs processing for smoothing fluff peculiar to the fabric N by the preprocessing unit 17 .

[0084] Therefore, description of the same configuration as that of the first embodiment is omitted here, and the description will focus on the configuration unique to this embodiment, which is different from the first embodiment, that is, a configuration specific to a printing and dyeing device that performs printing on the fabric N.

[0085] The printing apparatus 1C according to this embodiment includes: a printing unit 5 for printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com