Salt distribution system for high-temperature molten salt storage tank

A high-temperature molten salt storage tank and molten salt technology, applied in the field of heat storage systems, can solve problems such as leakage accidents, uneven temperature distribution of molten salt, stress cracking at the tank bottom and tank wall welds, etc., to reduce thermal shock, The effect of avoiding stress cracking and solving the uneven temperature distribution of molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

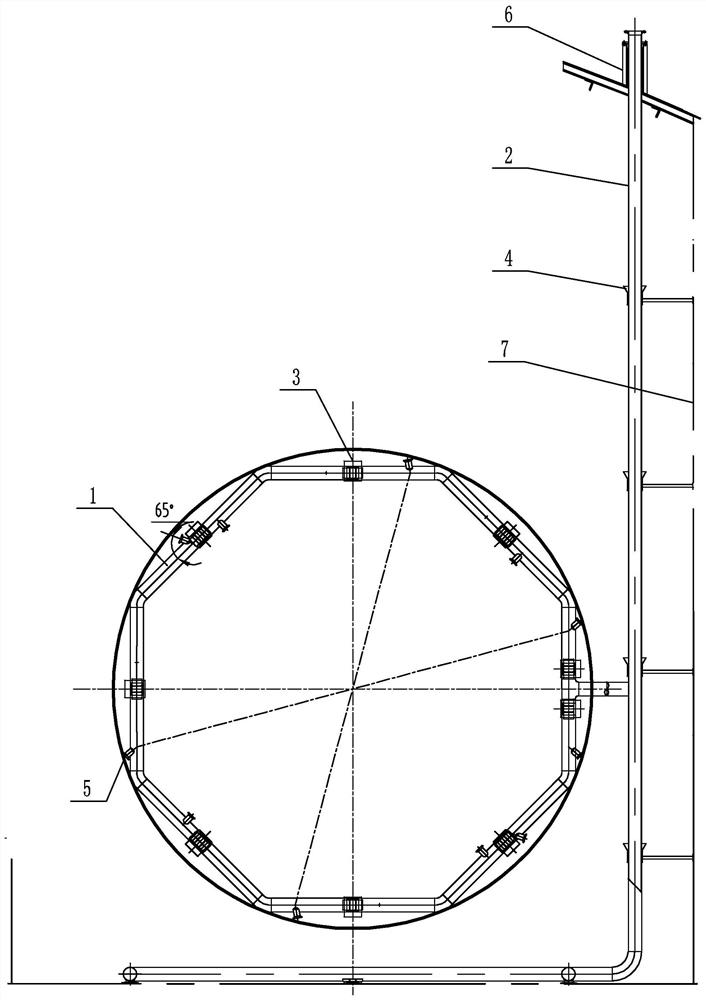

[0019] Specific implementation mode one: combine Figure 1 to Figure 11 To illustrate this embodiment, a salt distribution system for a high-temperature molten salt storage tank includes a tank bottom molten salt distribution ring 1, a vertical pipe section 2, a tank bottom support 3, a tank top connection structure 6, a nozzle 5 and multiple tank wall supports 4, The vertical pipe section 2 is vertically installed in the tank body 7 through a plurality of tank wall supports 4 arranged in sequence from top to bottom. The upper end of the vertical pipe section 2 is connected to the tank body 7 through the tank roof connection structure 6, and the molten salt distribution at the bottom of the tank The ring 1 is installed in the tank body 7 through the tank bottom support 3, and the tank bottom molten salt distribution ring 1 is connected with the vertical pipe section 2, the tank bottom molten salt distribution ring 1 is an octagonal ring, and the tank bottom molten salt distribu...

specific Embodiment approach 2

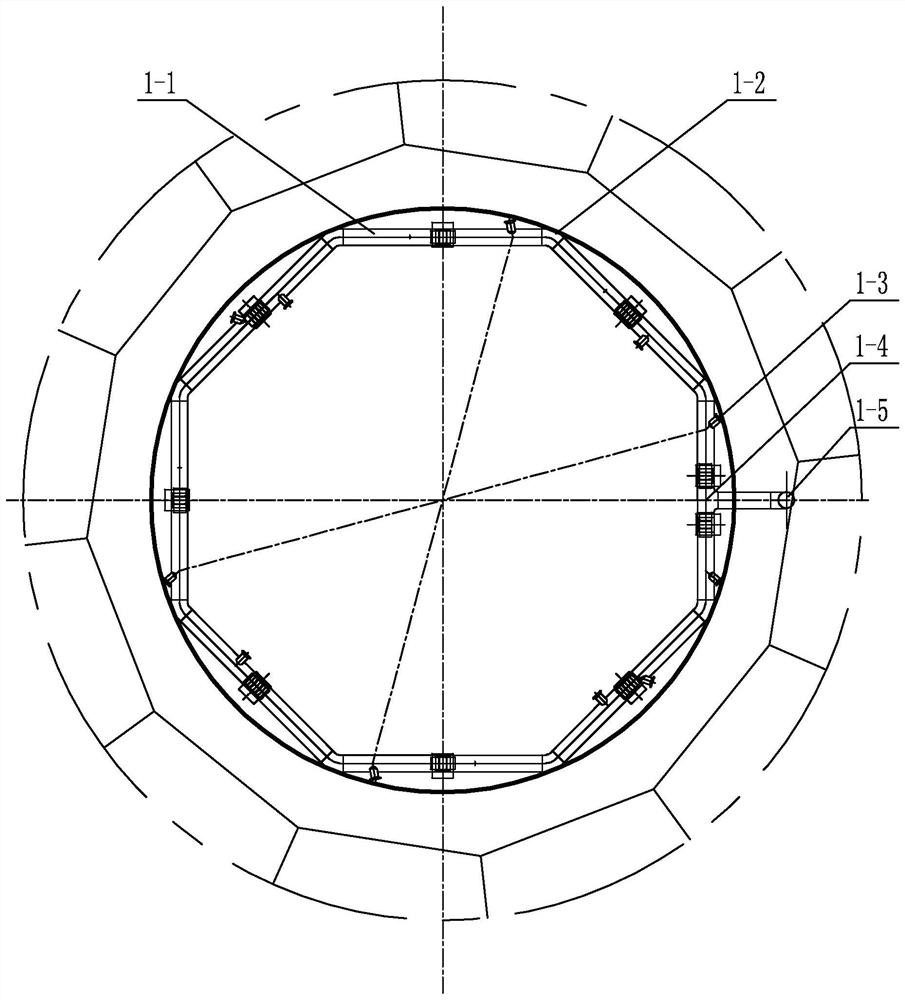

[0023] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the tank bottom molten salt distribution ring 1 of this embodiment is a regular octagonal ring. With such arrangement, it is convenient to evenly distribute the molten salt into the whole tank body. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

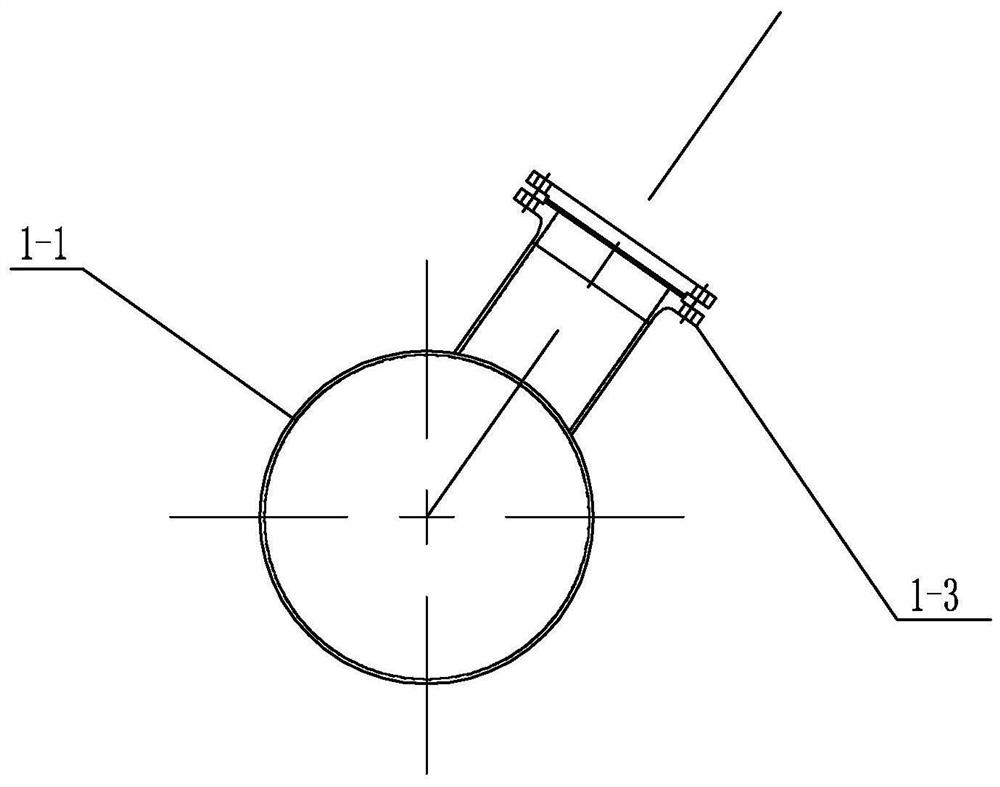

[0024] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the tank bottom molten salt distribution ring 1 of this embodiment includes a tee pipe 1-4, a plurality of straight pipe sections 1-1, a vertical section connection elbow 1-5, and a plurality of distribution ring connection elbows 1 -2 and multiple nozzle connecting flanges 1-3, the horizontal section of the tee pipe 1-4 and multiple straight pipe sections 1-1 are sequentially connected through multiple distribution rings to connect elbows 1-2 to form an annular pipe body At least one nozzle adapter flange 1-3 is installed on each straight pipe section 1-1, and the vertical section of the tee pipe 1-4 is connected to the vertical pipe section 2 through a vertical section connecting elbow 1-5. With such an arrangement, the structure is simple, and it is convenient for manufacture and connection, especially, it can form a ring shape, which provides convenient conditions for realizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com