Automatic detecting, transferring, overturning and stacking device for ultrathin strip-shaped pore plate corrugated plates and using method

A stacking device and perforated plate corrugation technology, which is applied to conveyor control devices, object stacking, transportation and packaging, etc., can solve the problems of low production efficiency, the length of the device turning mechanism cannot be less than 4.9 meters, etc., to improve work efficiency. Efficiency, eliminating mechanical repetitive labor, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

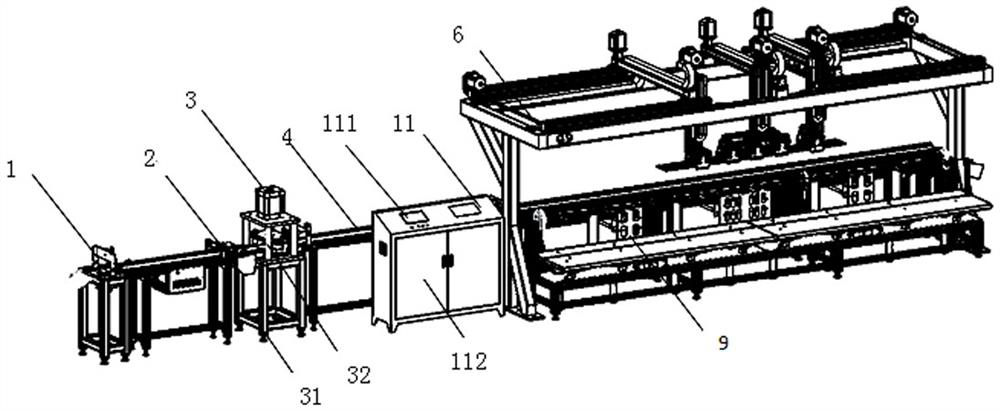

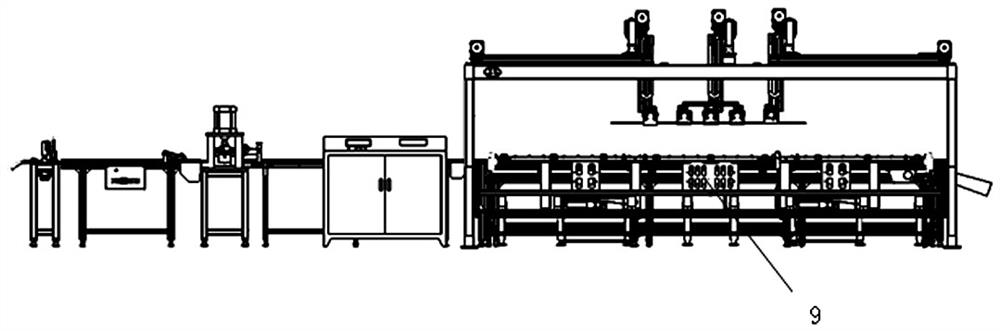

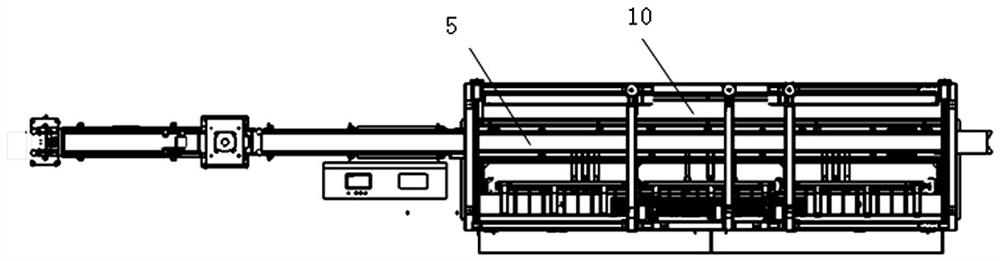

[0043] Such as Figure 1-18 As shown, an ultra-thin belt-shaped orifice plate corrugated plate automatic detection, transfer, flipping and palletizing device includes an automatic detection device 1, a length measuring device 2, a shearing device 3, a buffer conveying device 4, a feeding conveying device 5, Lifting and transplanting device 6, turning device 7, lifting stacking device 8, material pushing device 9, waste conveying device 10, electric control device, are all provided with conveying track mutually, described automatic detection device 1 comprises support 92, and The width detection mechanism 11 and the height detection mechanism 12 arranged on the upper end of the bracket 92; the length measuring device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com