A fully automatic intelligent logistics picking equipment

An intelligent logistics and fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inflexible adjustment, low automation of logistics parcel picking, and small range of mobile adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be described below in conjunction with examples, as will be described herein, and is merely the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in the scope of the present invention without any other embodiments obtained without creative labor.

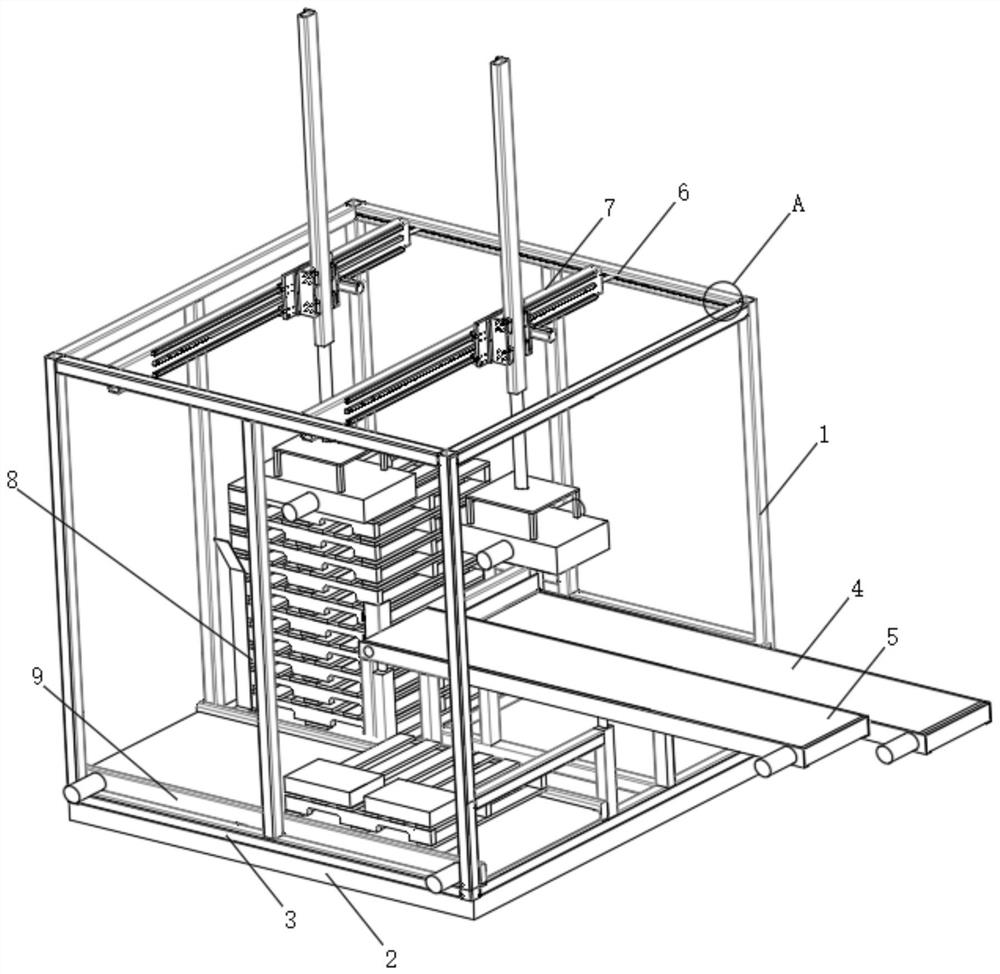

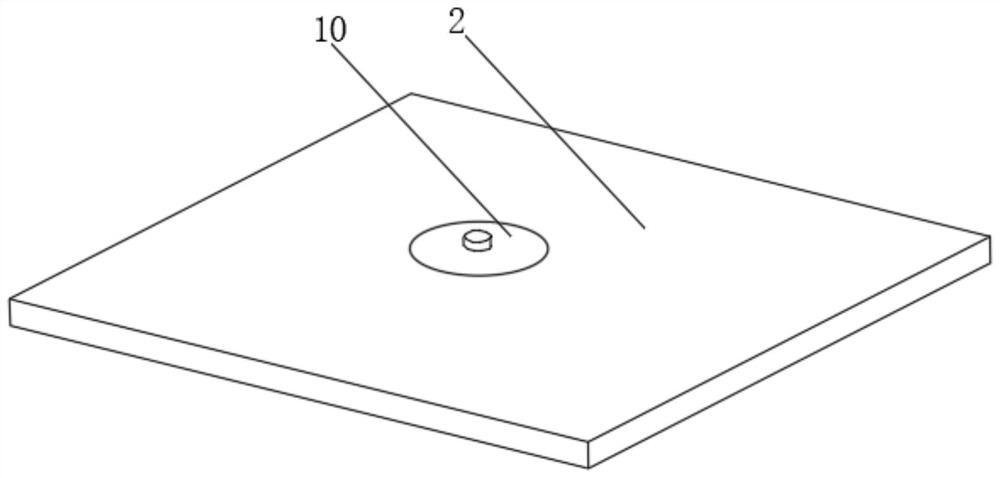

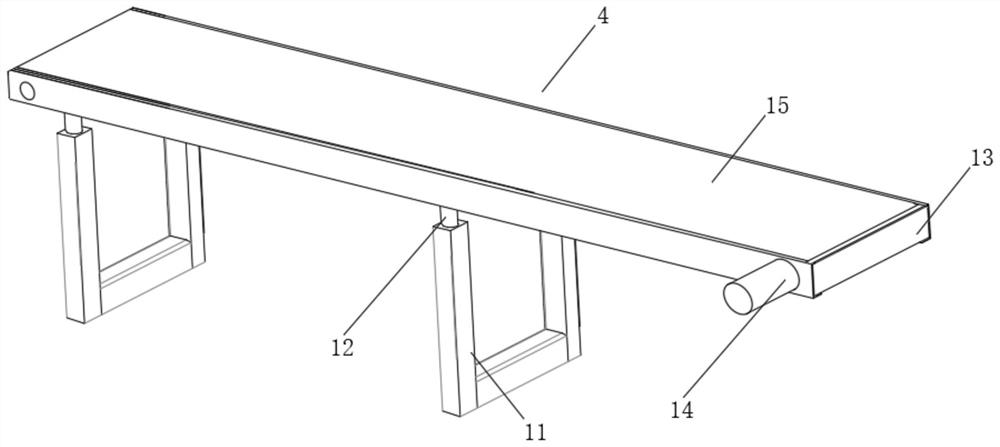

[0043] See Figure 1-11 As shown, a fully automated intelligent logistics picking device, including the loading frame 1, a base 2 having a rectangular form structure, a first orientation disk 4, and a selection rack 7, the base 2 is located below the loading frame, and the base 2 is set There is a first motor 10, and the first motor 10 is rotated by the output shaft, and the loading frame 1 is provided with the first mold disk 4, and the first mold disk 4 is provided with a second mold disk. 5, the second mold disk 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com