Method for preparing N-(6-chloro-3-pyridylmethyl) methylamine by micro-channel reactor

A technology of microchannel reactor and channel reactor, which is applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc. Long time and other problems, to achieve the effect of improving yield, improving safety performance, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

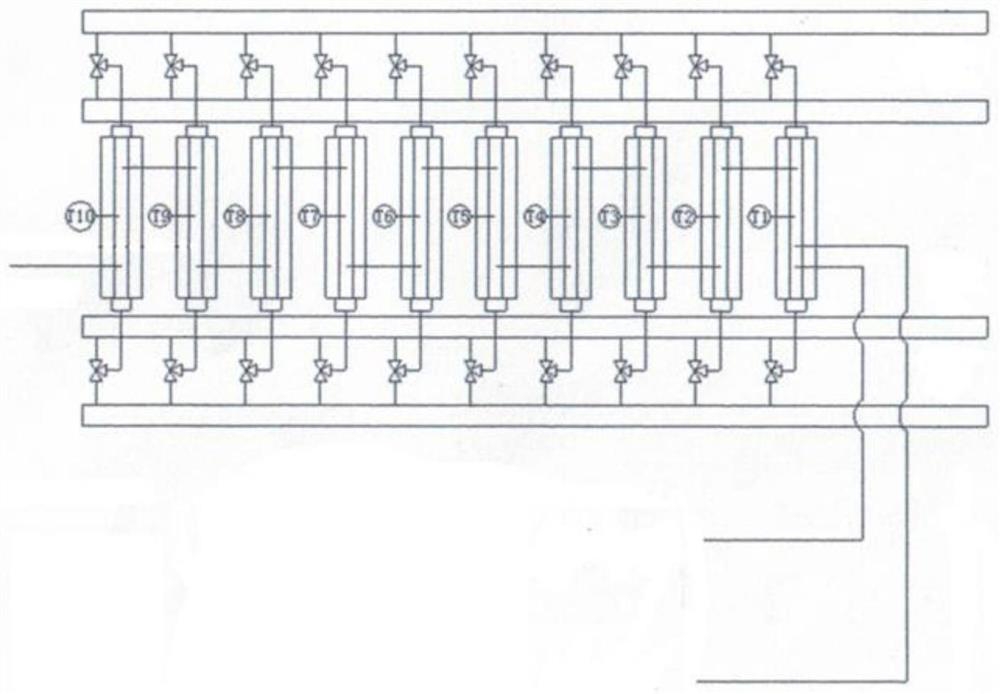

[0022] see Figure 1-2

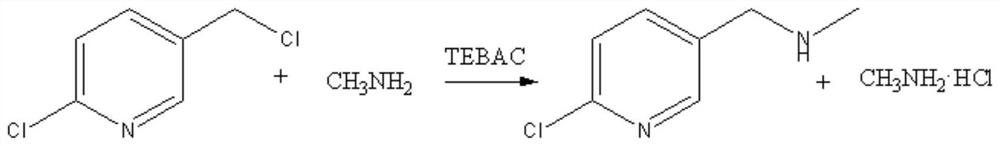

[0023] Known by above technical scheme, a kind of microchannel reactor prepares the method for N-(6-chloro-3-pyridylmethyl)methanamine, comprises the steps:

[0024] A. Add monomethylamine aqueous solution and TEBAC aqueous solution to the silk bottle, shake well to form a solution for later use;

[0025] B. Add liquid 2-chloro-5-chloromethylpyridine and an organic solvent into a four-necked flask equipped with stirring, condenser and thermometer, and stir to form a uniform and stable solution for subsequent use;

[0026] C, two streams of solutions are pumped into the microchannel reactor reaction simultaneously to obtain the mixture containing N-(6-chloro-3-pyridy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com