Intelligent blanking size calculation system for various types of multiple part blanks

A blank and blanking technology, applied in the field of intelligent blanking size calculation system, can solve problems such as waste of leftovers, inability to realize process pre-processing, and lack of intelligent management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

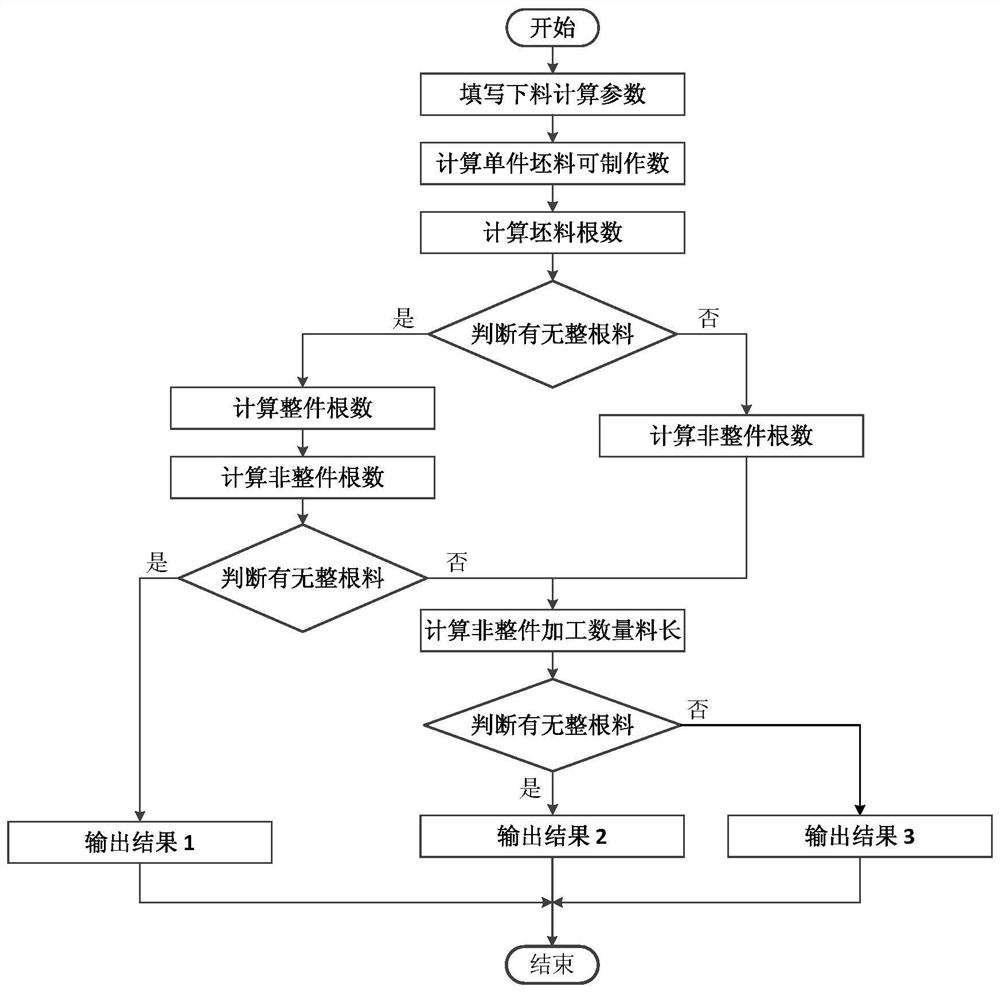

[0261] Example (1): Bar material blanking

[0262] Fill in the calculation parameters of bar blanking as shown in Table 1.

[0263] Table 1 Bar blanking calculation parameters

[0264]

[0265] The production quantity is 200 pieces. The blank blanking results are as follows:

[0266] "Saw: 250.00-4 pieces; 99.50-1 piece".

[0267] After verification and calculation, the blank blanking result of the system is correct.

[0268] Reference Image 6 , The system automatically fills in the content and requirements of the blanking process (step), and indicates the remarks in it.

Embodiment ( 2

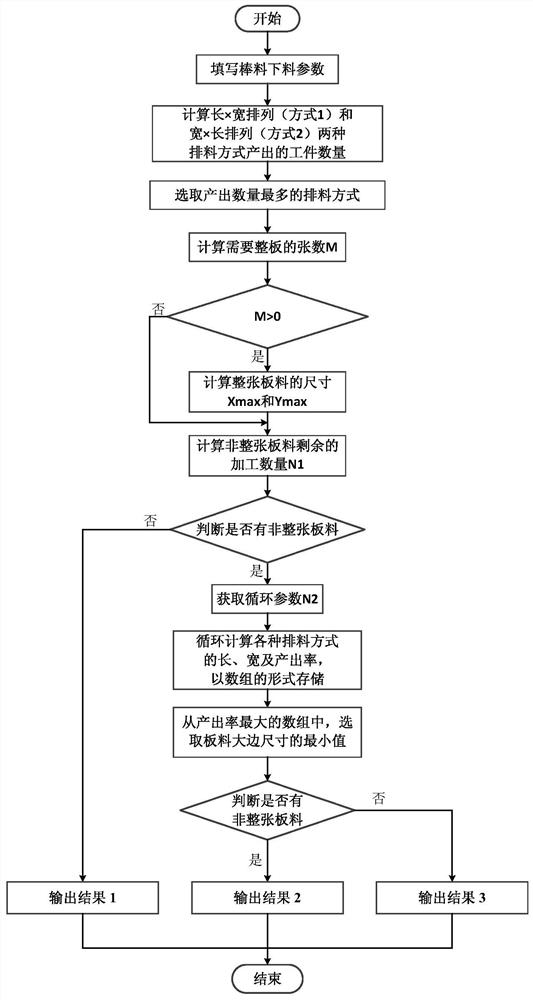

[0269] Example (2): Single sheet size blanking

[0270] Fill in the blanking calculation parameters as shown in Table 2.

[0271] Table 2 Blanking calculation parameters

[0272]

[0273] The production quantity is 12 pieces. The blank blanking results are as follows:

[0274] "Cut: 2371.00×1145.00-2 pieces (3×2)".

[0275] After verification and calculation, the blank blanking result of the system is correct.

[0276] Reference Figure 7 , The system automatically fills in the content and requirements of the blanking process (step), and indicates the remarks in it.

Embodiment ( 3

[0277] Embodiment (three): two kinds of sheet material specifications blanking

[0278] The calculation parameters of the combined blank blanking are shown in Table 3.

[0279] Table 3 Sheet blanking calculation parameters

[0280]

[0281] The production quantity is 20 pieces. The blank blanking results are as follows:

[0282] "Cut: 1853.00×1440.00-2 pieces (10×2)".

[0283] After verification and calculation, the blank blanking result of the system is correct.

[0284] Reference Picture 8 , The system automatically fills in the content and requirements of the blanking process (step), and indicates the remarks in it.

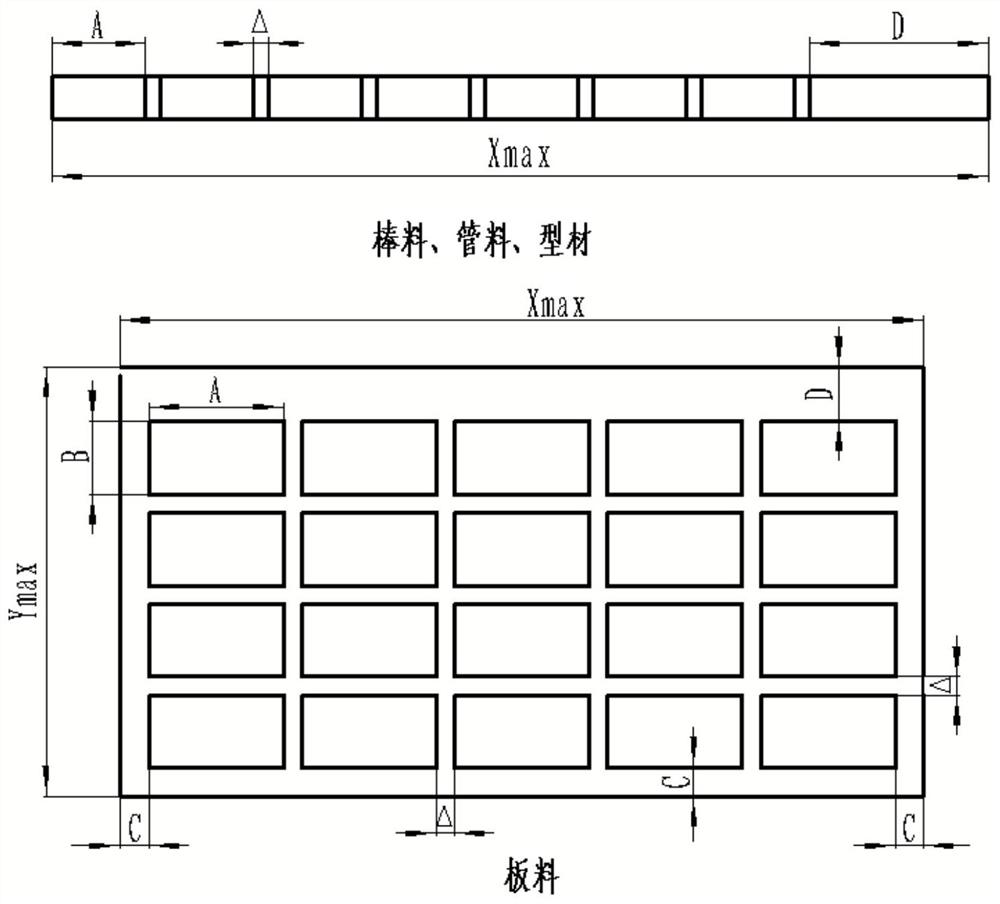

[0285] In short, the present invention first fills in the corresponding blanking parameters in the process card; then according to the product production set quantity given in the processing task sheet, the production quantity of the parts is determined by the number of parts in the manufacturing bill of materials; then the calculation formula is used , Boundary condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com