Semiconductor chip packaging structure and packaging part thereof

A technology of chip packaging structure and packaging components, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low paste efficiency and low degree of automation, achieve high paste efficiency, high degree of automation, and facilitate automatic paste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

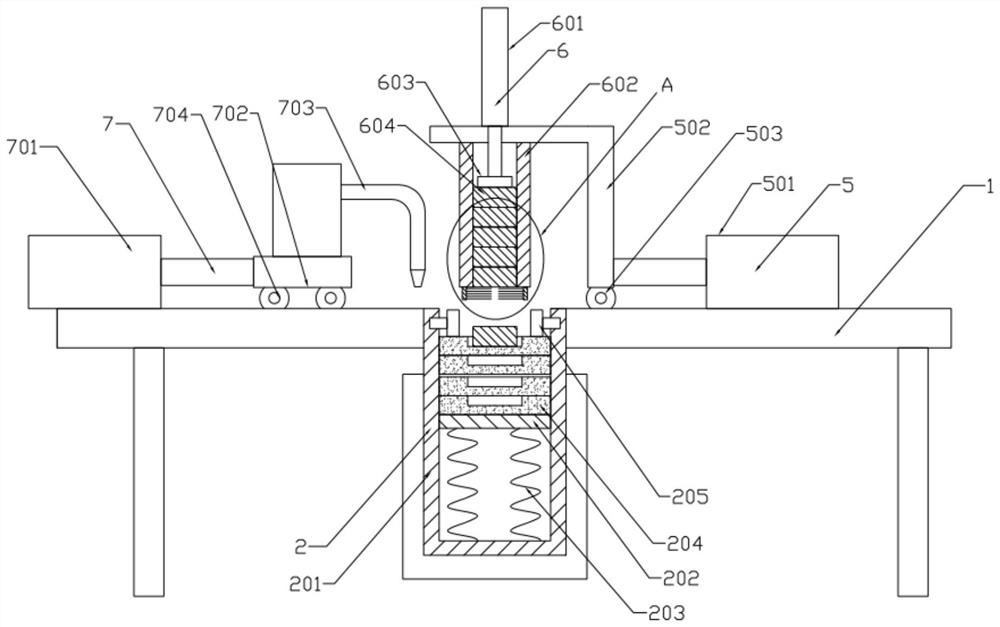

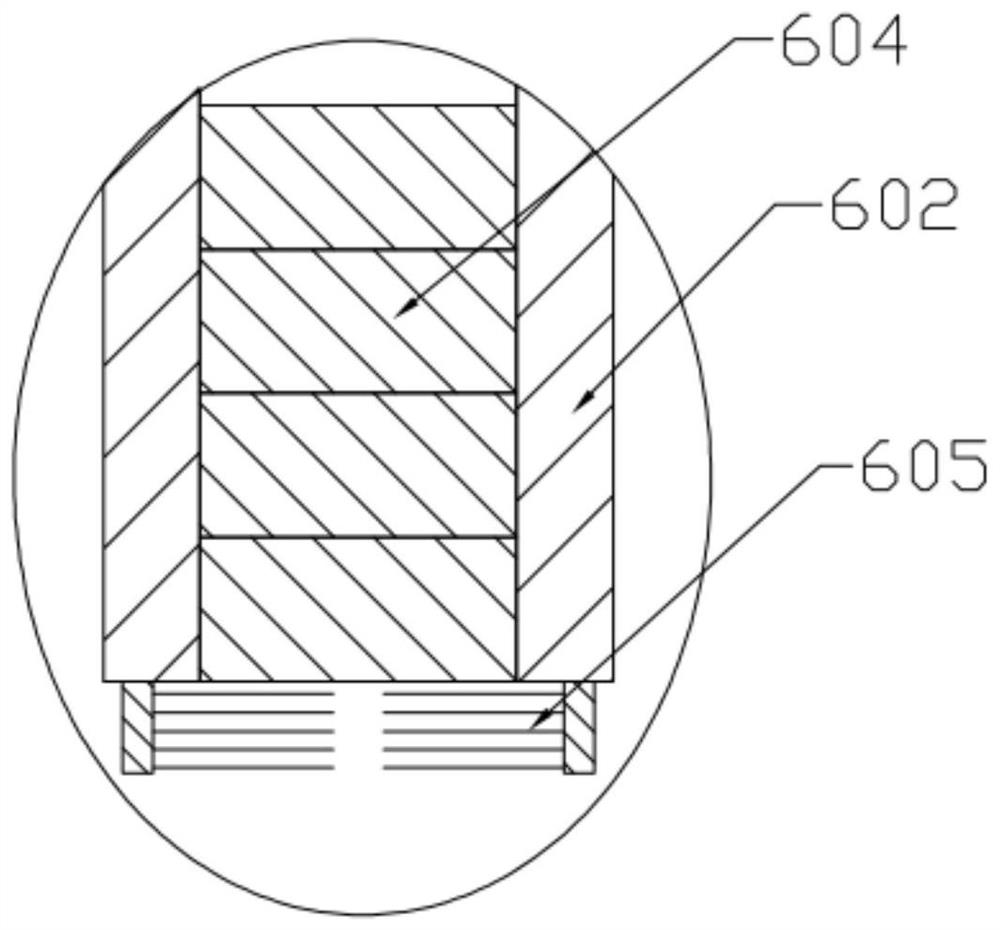

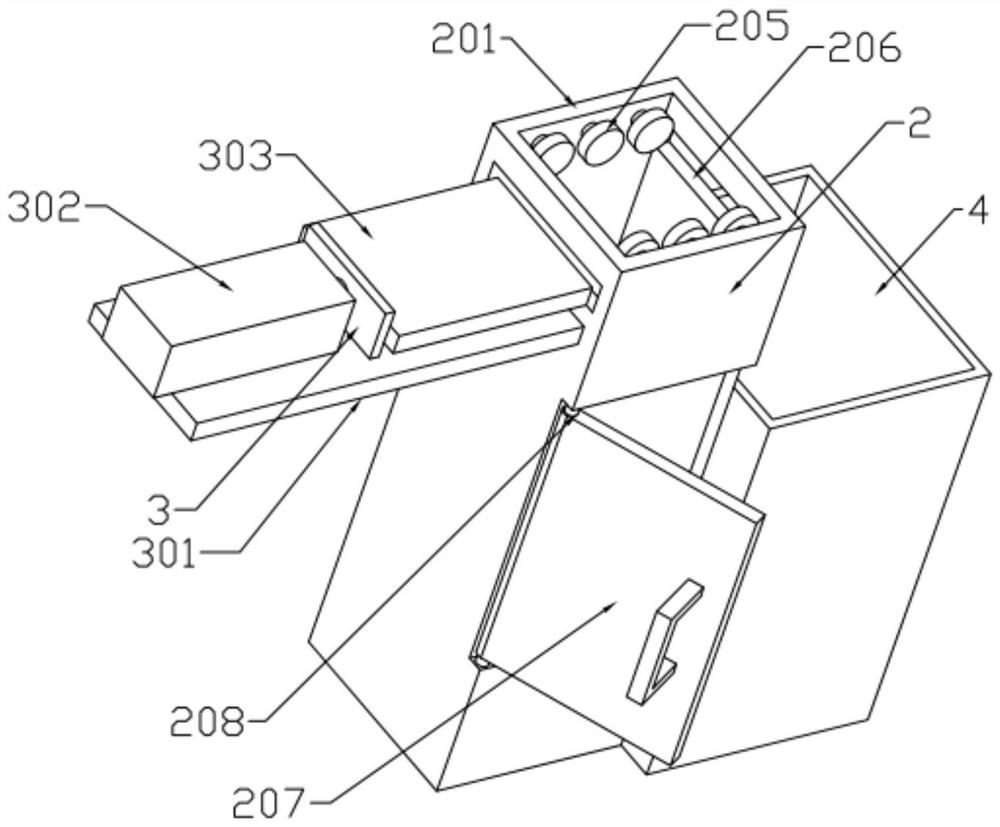

[0020] See Figure 1~3 In an embodiment of the present invention, a semiconductor chip packaging structure and its packaging components include a workbench 1, on which a substrate transport mechanism 2 is installed, and the substrate transport mechanism 2 includes: a storage shell 201, a support plate 202, a compression spring 203, a base plate 204, a limit roller 205, a discharge port 206, a cover plate 207 and a pin shaft 208, the storage shell 201 is connected to the workbench 1 by screws, and a support plate is installed in the storage shell 201 202. The support plate 202 is elastically connected to the inner bottom end of the storage case 201 through a plurality of compression springs 203. A plurality of substrates 204 are placed on the support plate 202. When the substrate 204 is placed on the support plate 202, the compression springs 203 is in a compressed state. A plurality of limit rollers 205 are installed on the left and right sides of the inner top of the storage s...

Embodiment 2

[0022] See Figure 1~3 In the embodiment of the present invention, the blanking mechanism 3 includes a mounting plate 301, a first cylinder 302, and a pushing block 303. The mounting plate 301 is mounted on the left side of the storage shell 201, and the mounting plate 301 is screwed It is detachably linked to the storage shell 201, the mounting plate 301 is equipped with a first air cylinder 302, and the telescopic rod of the first air cylinder 302 is connected to a pushing block 303, which is T-shaped.

[0023] For the semiconductor chip packaging structure and its packaging components, the cover 207 is first opened to place the substrate 204 on the support plate 202, and then the bottom plate 702 is driven by the third cylinder 701, and the dispenser 703 is driven onto the substrate 204 through the bottom plate 702. After dispensing, the third cylinder 701 drives the bottom plate 702 and the dispenser 703 to return, and the second cylinder 501 drives the L-shaped plate 502 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com