Nuclear power plant auxiliary steam and steam turbine shaft seal steam pipeline joint purging method

A technology of auxiliary steam and shaft seal steam, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of power station inconvenience, installation and dismantling consume a lot of manpower and time, and occupy power station space, etc., to achieve Effects of improving cleanliness, shortening blowing time, and reducing use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

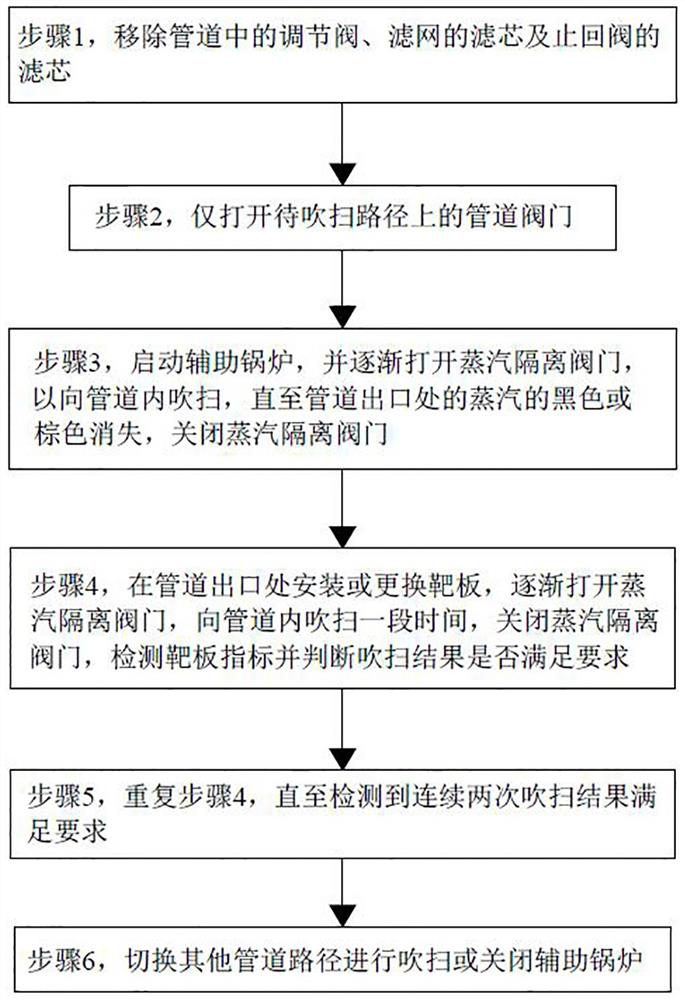

[0033] A method for combined purging of nuclear power plant auxiliary steam and steam turbine shaft seal steam pipelines, comprising the following steps:

[0034] Step 1, remove the regulating valve, the filter element of the filter screen and the filter element of the check valve in the pipeline;

[0035] Step 2, only open the pipeline valve on the path to be purged;

[0036] Step 3, start the auxiliary boiler, and gradually open the steam isolation valve to purge the pipeline until the black or brown color of the steam at the outlet of the pipeline disappears, then close the steam isolation valve;

[0037] Step 4, install or replace the target plate at the outlet of the pipeline, gradually open the steam isolation valve, purge the pipeline for a period of time, close the steam isolation valve, check the target plate index and judge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com