A machine tool fixture

A technology of machine tool fixtures and clamping components, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve problems such as deformation, lower product quality, and inability to stably clamp workpieces, so as to improve stability, improve quality, The effect of strong economic extension value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

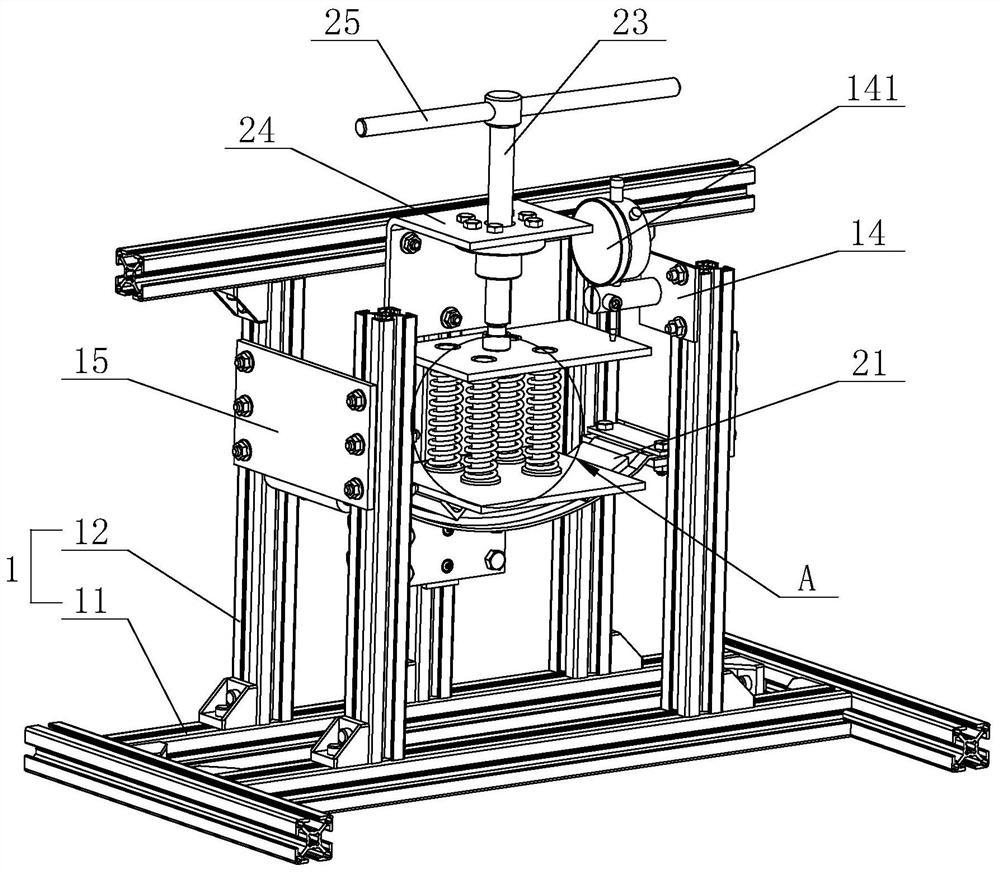

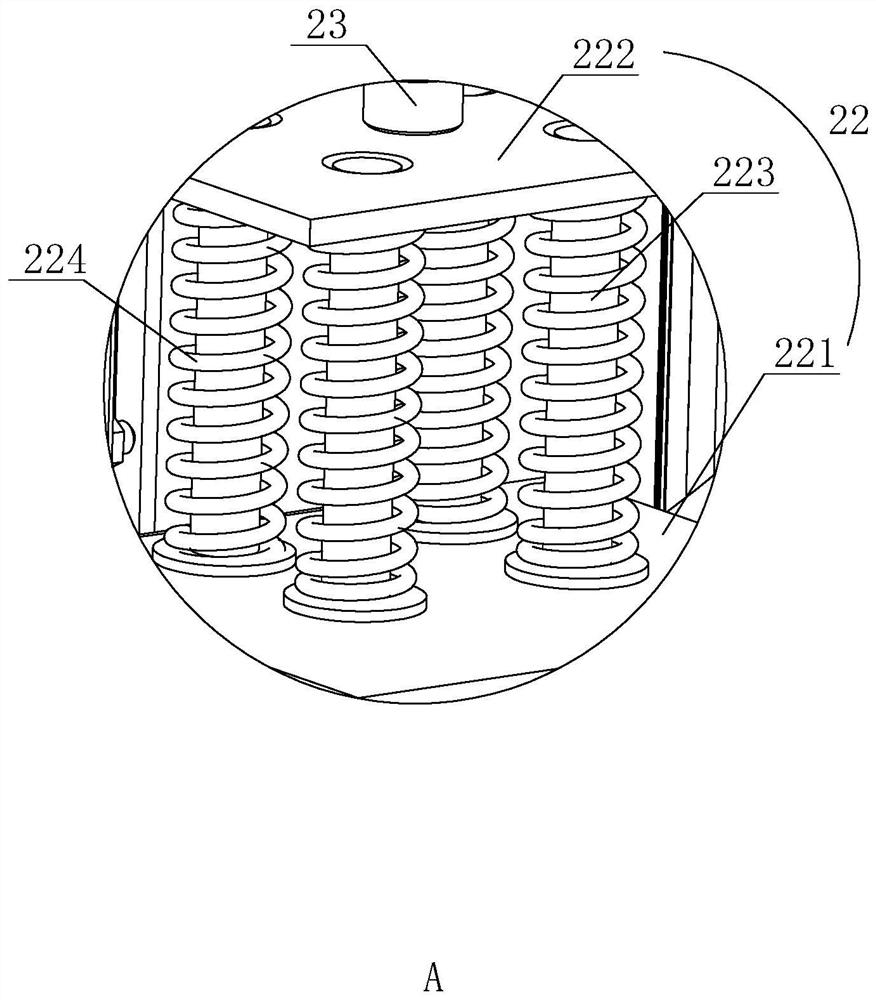

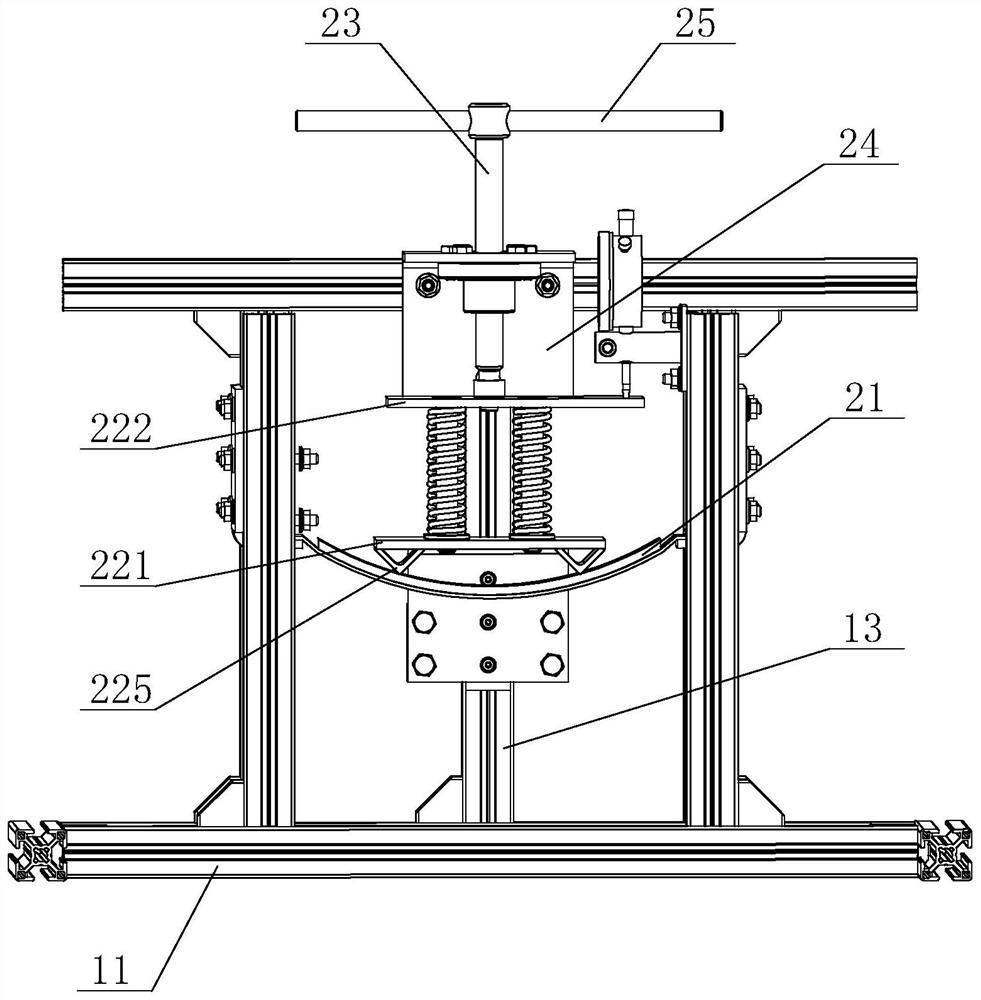

[0033] refer to figure 1 , is a machine tool fixture disclosed in the present invention, including a support assembly 1 and a clamping assembly, the support assembly 1 includes a base 11 and four support rods 12 fixed on the base 11, the clamping assembly includes a bottom plate 21, an elastic pressing part 22 and the lifting screw 23 used to adjust the lifting of the elastic pressing part 22, the bottom plate 21 is fixed between the four support rods 12. A reinforcement plate 15 is arranged between the two support rods 12 , both ends of the reinforcement plate 15 are fixed on the support rods 12 by bolts, and the reinforcement plate 15 is detachably and fixedly connected to the bottom plate 21 . The reinforcing plates 15 are respectively fixed between the two supporting rods 12, which increases the stability of the fixture structure, and provides conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com