Plate feeder

A plate feeding machine and plate feeding technology, which is applied to conveyor objects, lifting devices, lifting frames, etc., can solve the problems of position offset, inability to transport multiple plates, and plates unable to be positioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

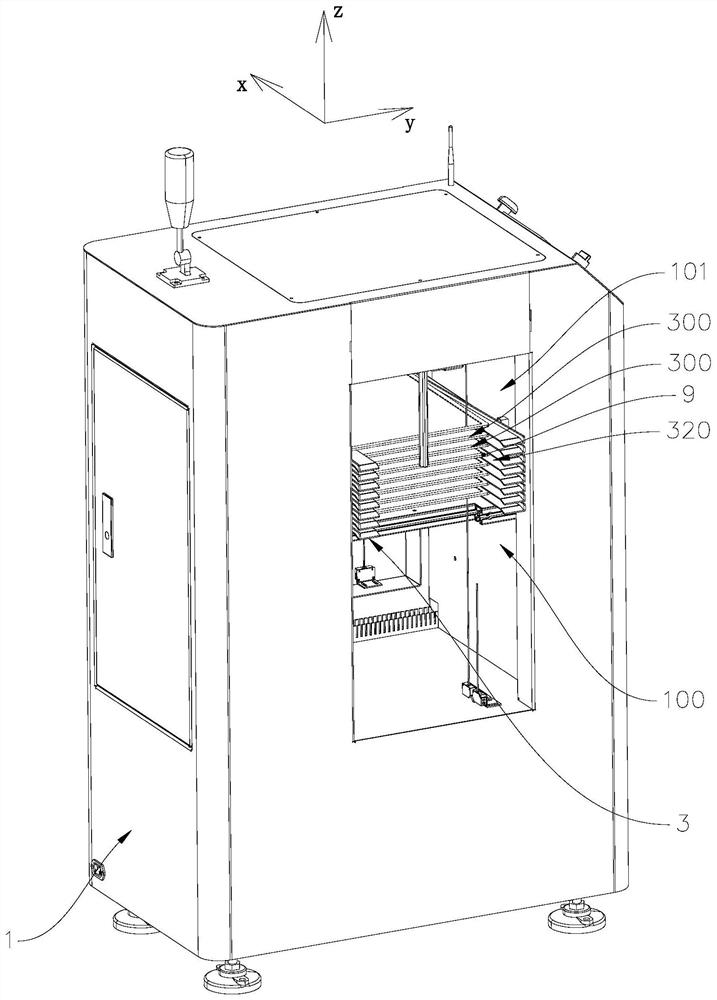

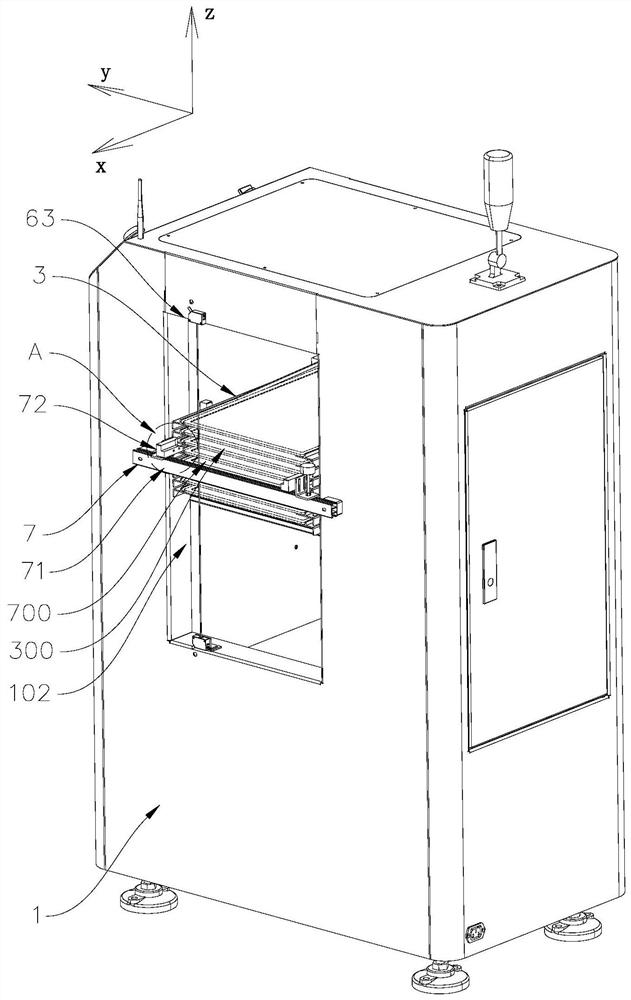

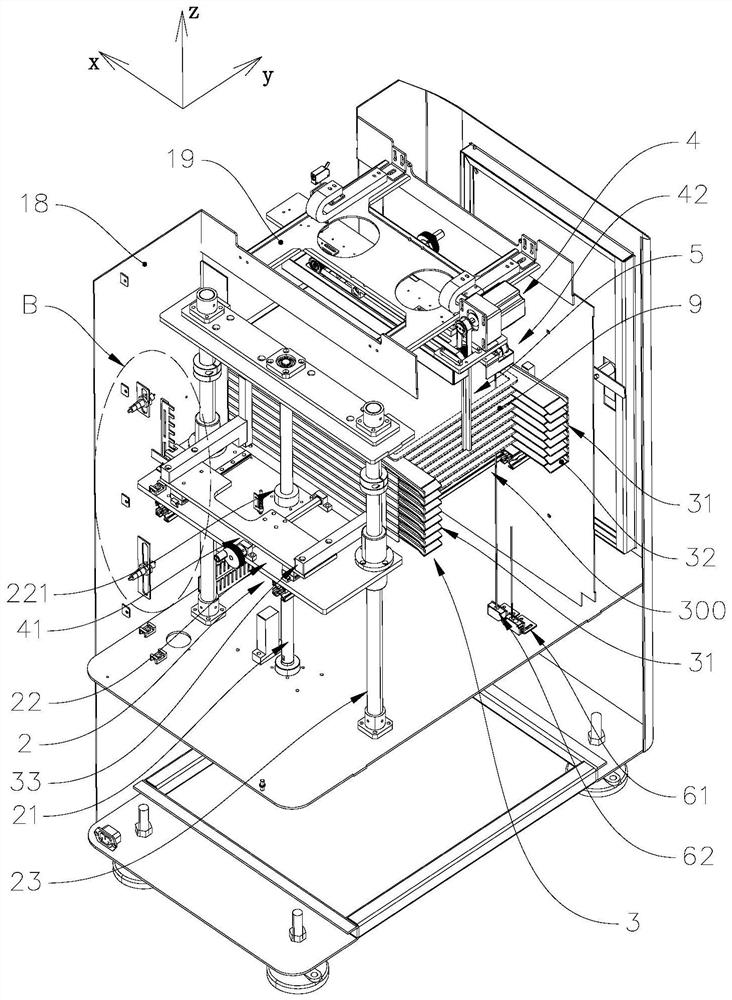

[0033] see Figure 1 to Figure 3 , figure 1 It is a structural diagram of the first viewing angle of the embodiment of the board feeding machine of the present invention, figure 2 It is a structural diagram of the second perspective of the embodiment of the board feeding machine of the present invention, image 3 A structural diagram of a part of the shell of the body is hidden for the embodiment of the board feeding machine of the present invention. A unified space Cartesian coordinate system is established in the drawings, the x-axis direction is the first horizontal direction, the y-axis direction is the second horizontal direction, and the z-axis direction is the vertical direction. The board feeding machine includes a body 1, a lifting device 2, a board holding device 3, a pushing device 4, a detection device group and a sending guide mechanism 7, and the detection device group includes a first photoelectric sensor 61 and a second photoelectric sensor 62 arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com