Channel plate underwater grouting stabilizing and lifting method

A channel and grouting technology, applied in the field of channel slab reinforcement and repair, can solve the problems of channel slab subsidence and sliding damage, difficult cement stabilization and uplift, gravel and sand layer taking away, etc., to achieve rapid repair and anti-seepage reinforcement, prevent Loosening and sliding damage, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

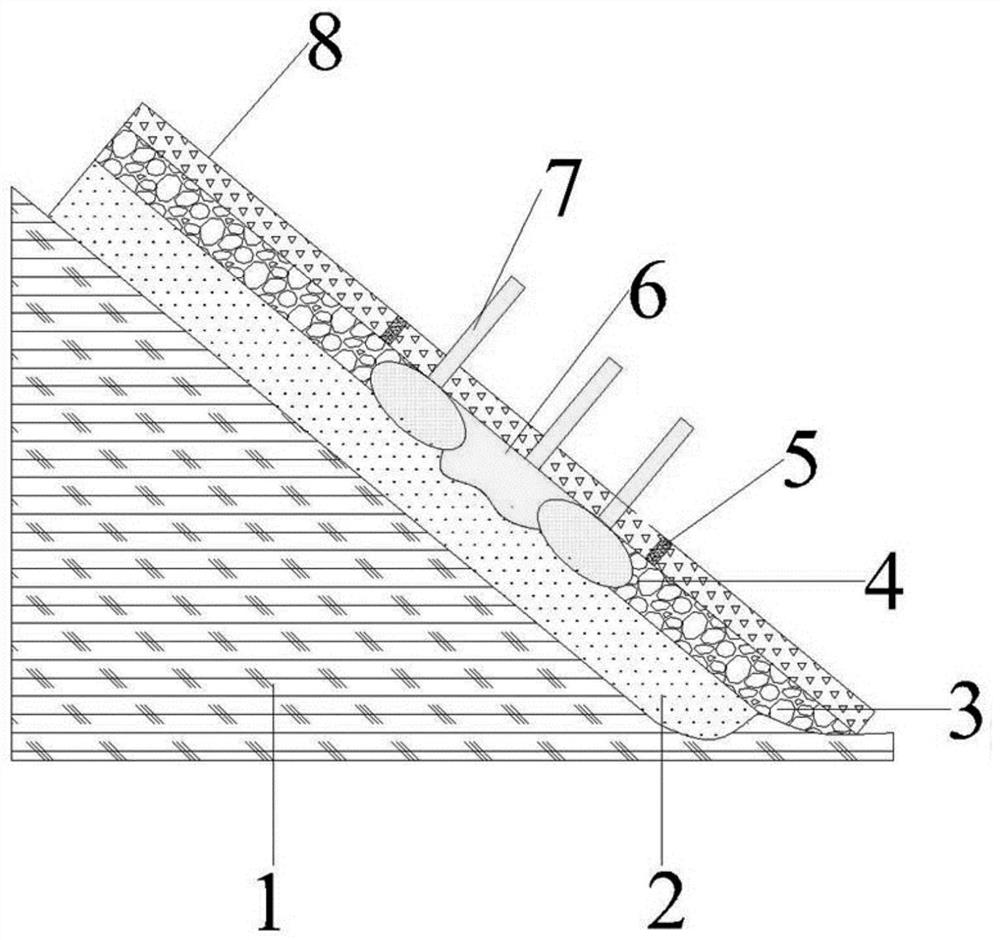

[0047] Embodiment 1, this embodiment takes the replacement of a damaged channel plate underwater as an example, for specific methods see figure 1 , image 3 , the specific construction process is as follows:

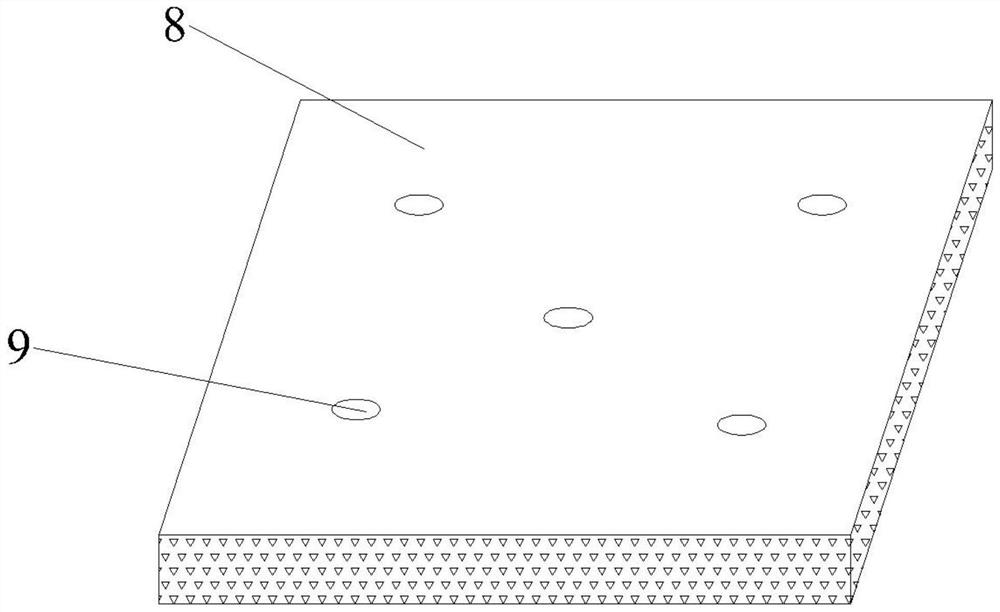

[0048] Step a, clean up the silt on the surface of the damaged channel board and the caulking materials in the joints, take out the damaged channel board, clean up the bonding material on the surface of the crushed stone layer, and level the crushed stone layer, take a new channel plate to be drilled, in accordance with image 3 Arrange the grouting holes, bind the geotextile bags on the grouting conduits, place the grouting conduits with geotextile bags in the grouting holes at the four corners of the channel plate, and place the grouting conduits without geotextile bags in the grouting holes in the middle of the channel plate , place the channel plate with the grouting conduit on the gravel layer;

[0049] Step b, adjust the grouting equipment, first fill the geotex...

Embodiment 2

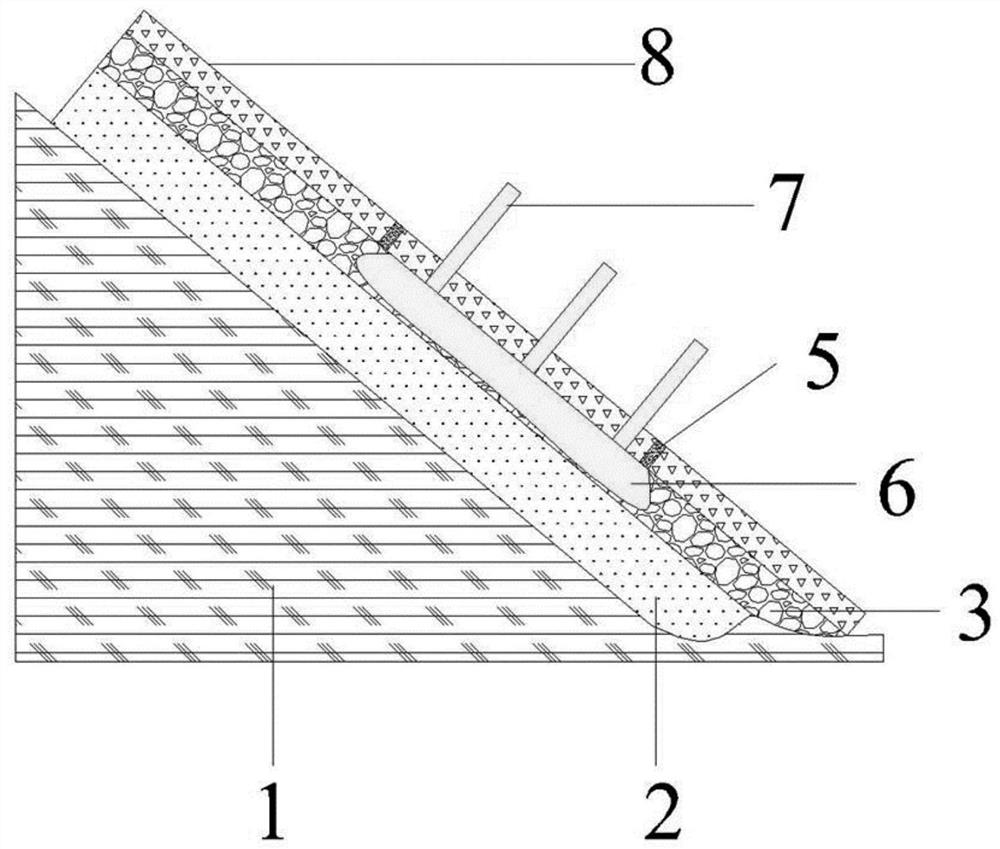

[0052] Embodiment 2, this embodiment takes the example of lifting the channel plate that sinks underwater, and the specific method can be found in figure 2 , image 3 , the specific construction process is as follows:

[0053] Step a, drill holes on the channel plate, according to image 3 Arrange the grouting holes, and place the grouting conduit on the channel plate;

[0054] Step b. Adjust the grouting equipment. First, grout the four corners of the channel plate in a diagonal form, and finally grout in the middle position. Since it takes 10-20 seconds for the polymer grout to fully expand, it needs to be injected every time. Stop and observe for 10 seconds, and stop grouting until it is flush with the original channel plate;

[0055] Step c, use a pipe cutter to cut off the excess grouting conduit, and smooth the incision with a file;

[0056] Step d: Clean excess polymer spilling from the seam on the channel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com