Cover-excavation top-down underground passage structure and construction method thereof

An underground passage, cover and dig reverse work technology, applied in the field of construction engineering, can solve the problems of long construction period, narrow work space, high construction cost, reduce construction cost and construction period, simple construction process, and solve the effect of narrow work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

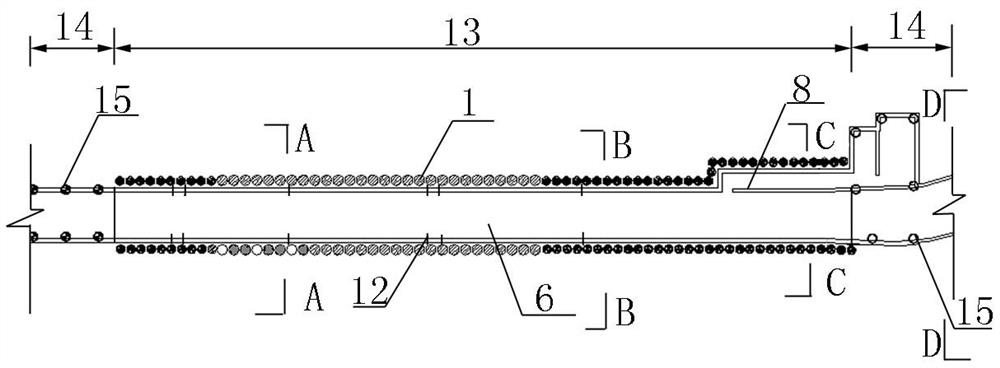

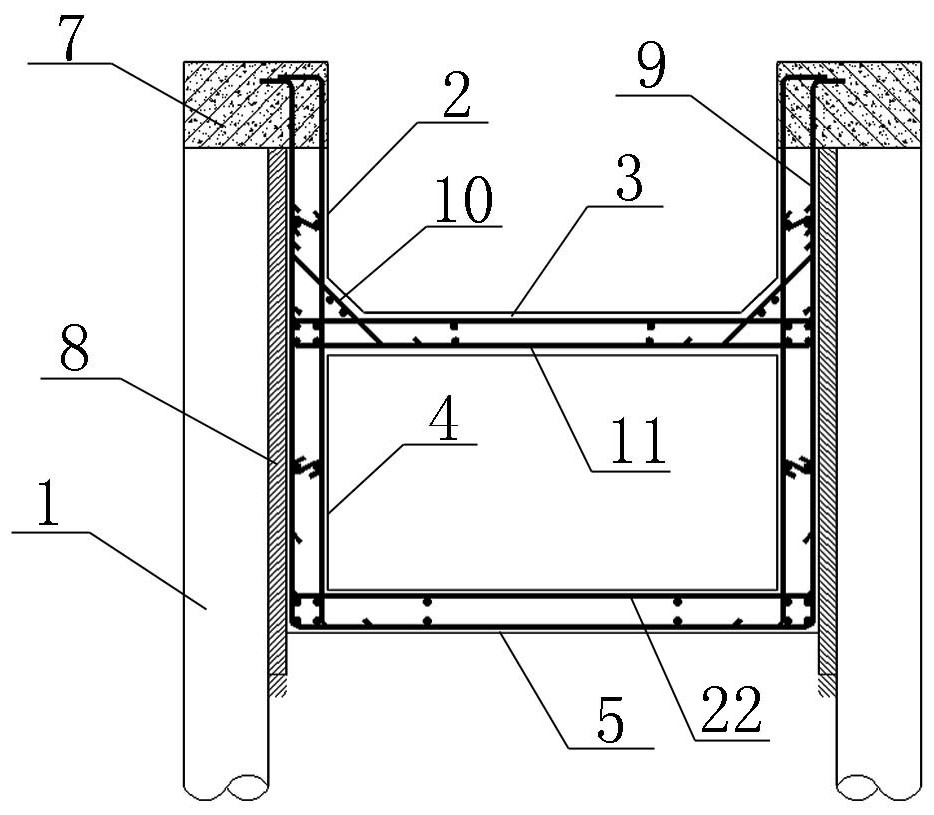

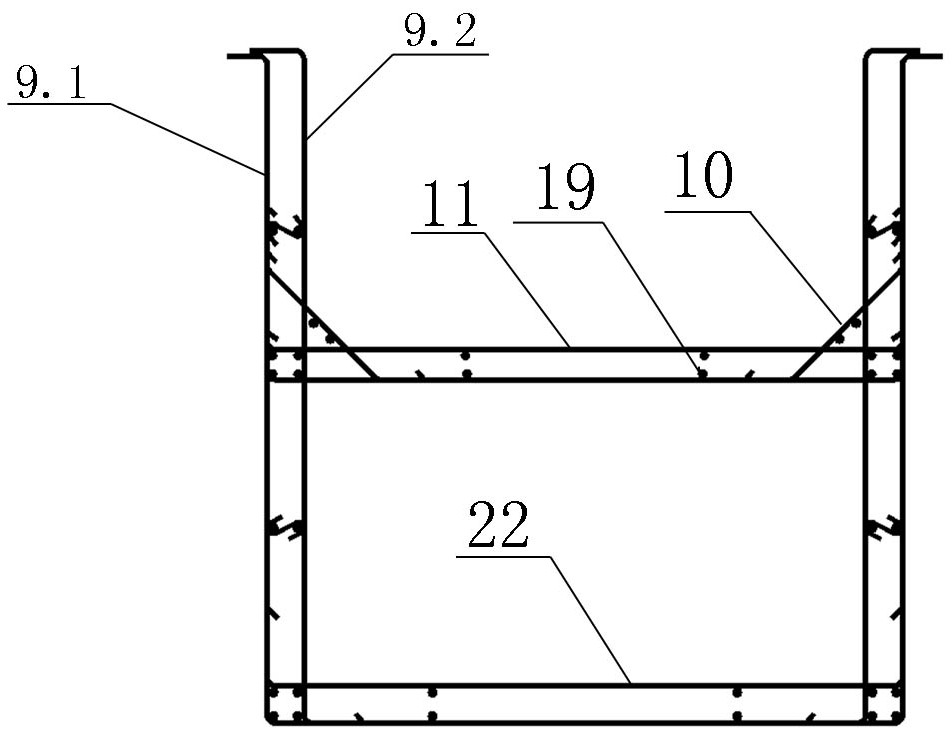

[0040] In this embodiment, the pile foundation construction is carried out first in the cover-excavation and reverse work area. After the pile foundation construction is completed, the wall laitance is removed, the debris at the pile head is cleaned, and the crown beam 7 and the hanging wall reinforcement 9 are tied. The part beyond the bottom surface of the crown beam 7 is connected with the top horizontal steel bar 11, and then the formwork is supported and the concrete for the roof 3 and the hanging wall 2 is poured. After the concrete strength reaches 100%, it can be backfilled and handed over to the area above the underground passage for anti-terrorism warning The building is under construction outdoors.

[0041] After the earthwork backfilling in the cover-excavation area is completed, the excavation of the lower layer of earthwork needs to wait for the open excavation area 14 on both sides to be excavated to the bottom of the pit, and then the excavator will excavate fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com