Self-learning rotational speed control method based on active observation of load change rate

A load change and control method technology, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as poor speed control quality, achieve the effects of improving robustness, reducing calibration workload, and improving control quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

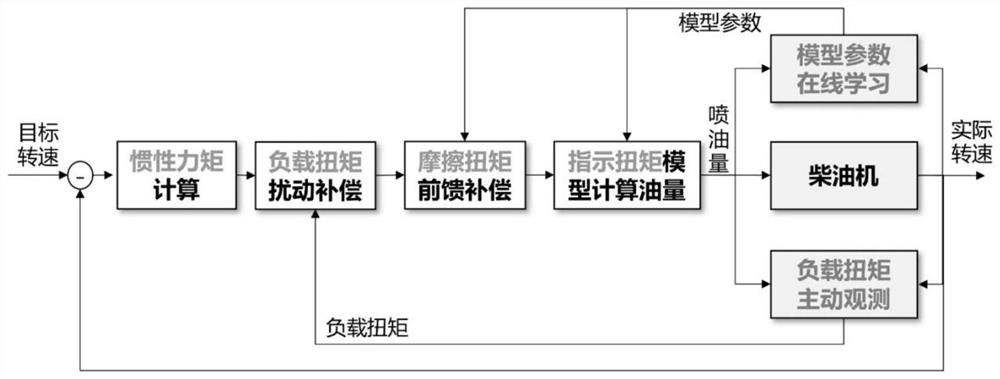

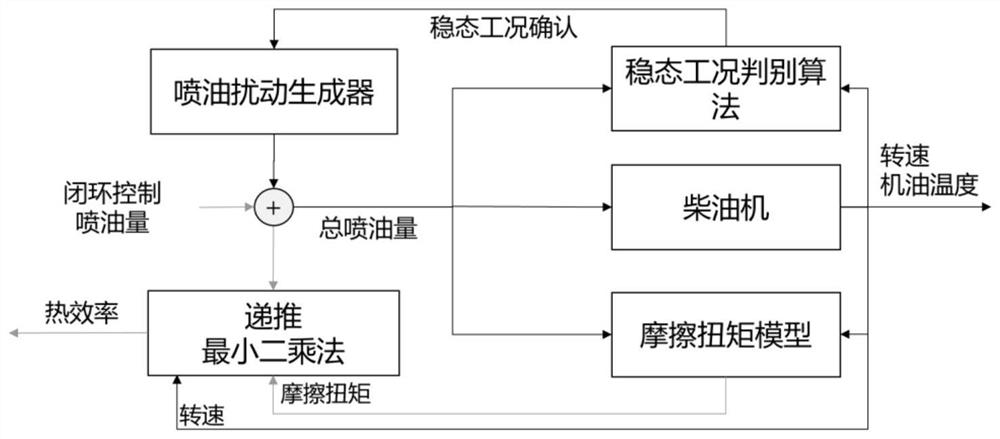

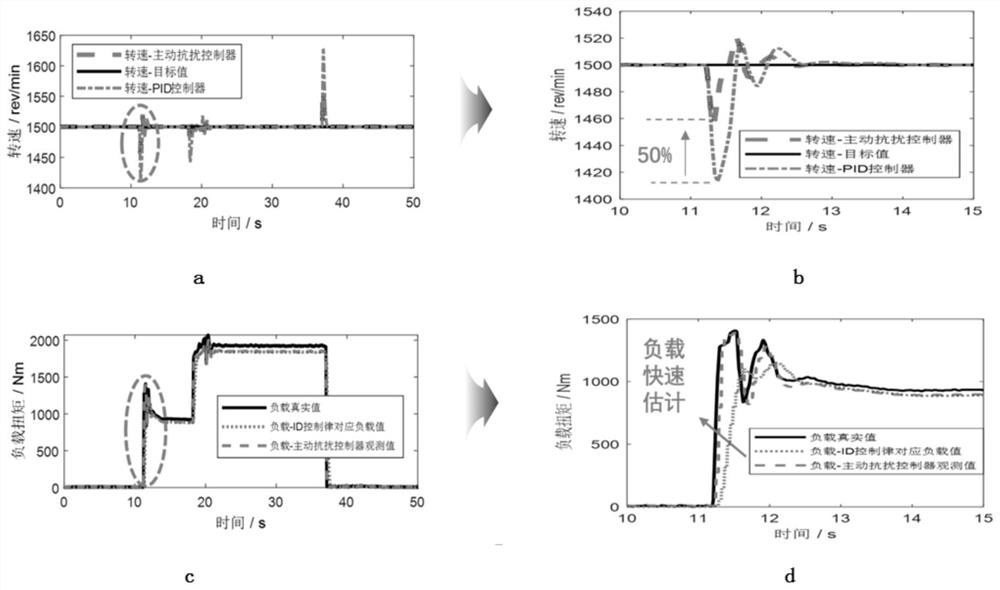

[0045] A method for self-learning control of engine speed based on active observation of load change rate, comprising the following steps:

[0046] Step 1, according to the deviation between the target engine speed and the actual engine speed, calculate the required moment of inertia through feedback control; use the friction torque model to estimate the current friction torque to obtain the friction torque;

[0047] Step 2, aiming at the dynamic change process of the engine speed, on the basis of the dynamic speed, add two "expansion states" of load torque and load torque change rate;

[0048] Step 3, using the reduced-order extended state observer method, combined with the friction torque, to observe the rotational speed, load torque and load torque change rate online, and obtain an estimated value of the load torque;

[0049] Step 4, on the basis of the moment of inertia obtained in step 1, use the estimated value of the load torque observed in step 3 to make compensation t...

Embodiment 2

[0056] Further, in the step 1, the moment of inertia u 0 The calculation method is:

[0057] u 0 =k p (ω ref -ω) (1)

[0058] where: ω ref is the target engine speed (unit: rpm), ω is the actual engine speed (unit: rpm), the engine can be a diesel engine, k p It is a proportional coefficient, which can be adjusted according to the required speed response speed.

[0059] Furthermore, in the step 2, the differential equation model of the engine speed adds two "expansion states" to obtain a speed dynamic model with expansion states:

[0060] Rewritten as formula (2):

[0061]

[0062] Among them, ω is the actual speed of the engine (unit: rpm), Represents the derivative of the actual engine speed, J is the moment of inertia of the crankshaft rotation system (unit: kg m 2 ), M i is the indicated torque (unit: Nm), M Fri is the friction torque (unit: Nm), M load is the load torque (unit: Nm).

[0063] To simplify the expression of (2), let As the equivalent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com