Vegetable quality-improvement device used for gardening cultivation

A vegetable and horticultural technology, which is applied in the field of vegetable quality improvement devices for horticultural cultivation, can solve the problems of inability to provide nutritional supplements, prevent and control diseases and insect pests, and achieve good root fertilization or pesticide application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

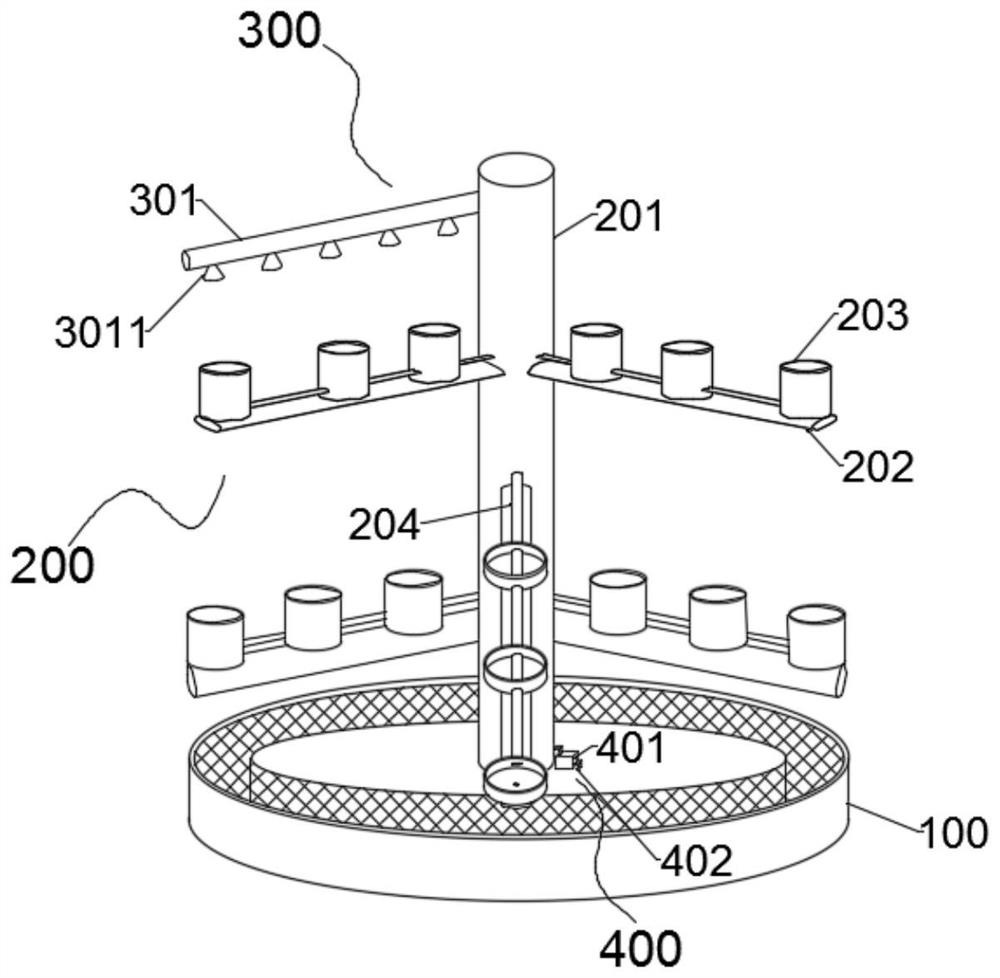

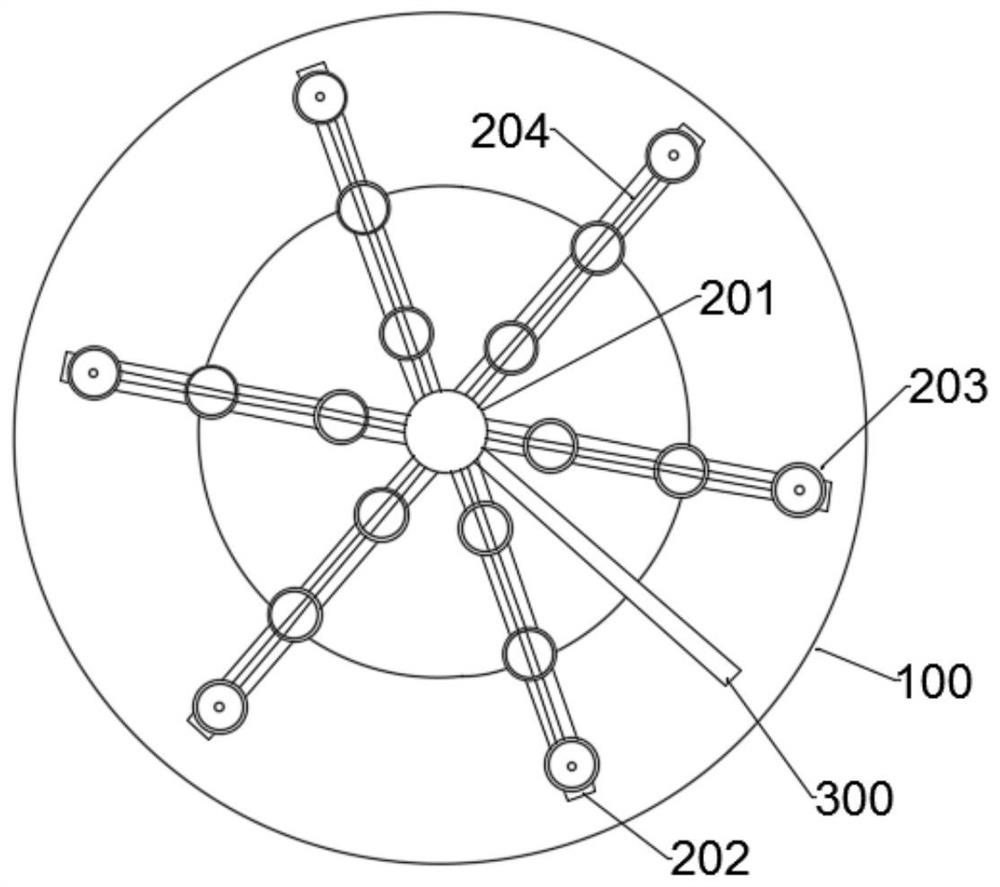

[0029] A vegetable quality improvement device for horticultural cultivation, such as Figure 1-2 As shown, it includes a fixed base 100 and a cultivation mechanism 200;

[0030] The surface of the fixed base 100 is provided with an annular groove 101, and the annular groove 101 is used for placing nutrient solution or liquid pesticide;

[0031] The cultivation mechanism 200 is fixed on the fixed base 100, including a vertical pole 201, a horizontal pole 202, a planting pot 203 and a catheter 204;

[0032] The vertical rod 201 is a hollow structure; the horizontal rod 202 surrounds and is arranged staggeredly on the outer periphery of the vertical rod 201 from top to bottom, and the end of the horizontal rod 202 is arranged obliquely downward;

[0033] The planting pots 203 are arranged on the cross bar 202 at intervals, and vegetables or other cultivated plants can be grown in the planting pots 203. Since the cross bars 202 are staggered, the growth light between each plant w...

Embodiment 2

[0039] The difference with embodiment 1 is:

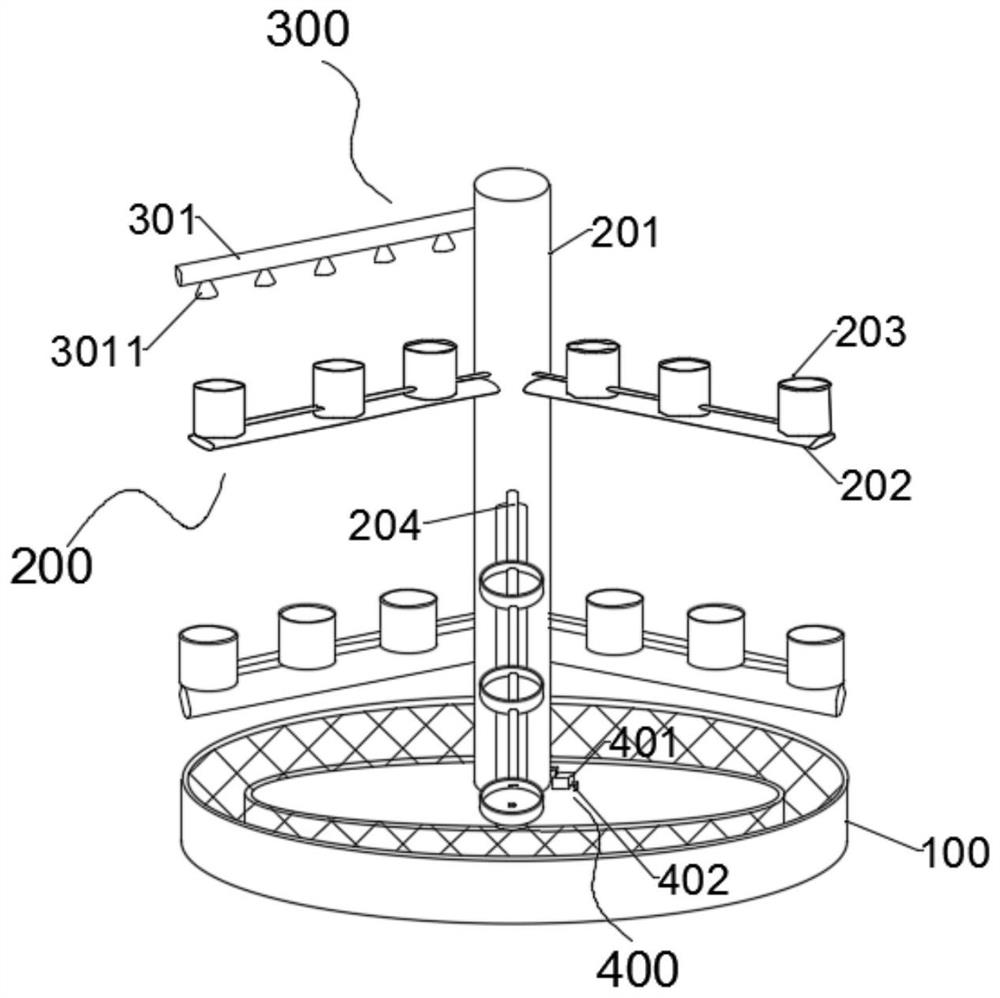

[0040] In order to prevent plant leaves or other debris from falling into the annular groove 101, thus affecting the normal operation of the extraction mechanism 400, the top of the annular groove 101 is provided with a partition to prevent the entry of debris, such as figure 1 shown.

Embodiment 3

[0042] The difference with the above-mentioned embodiment is:

[0043] After spraying the plant leaves from the spray pipe 301, the excess liquid will fall on the fixed base 100, part of it will enter the annular groove 101 for recycling, and part will fall on the fixed base 100 except the annular groove 101. , in order to enable this part of the liquid to be fully utilized, the top of the annular groove 101 is set lower than the upper surface of the fixed base 100, that is, from the edge of the annular groove 101 to the vertical rod 201, from the edge of the annular groove 101 to the fixed base The edges of 100 are slope-shaped, and the annular groove 101 is at the lowest point, so that the liquid at other places on the fixed base 100 will automatically flow into the annular groove 101 to be reused, as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com