Surface type reverse osmosis membrane filter element

A reverse osmosis membrane, surface-type technology, applied in reverse osmosis, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc., can solve problems such as water leakage, reverse osmosis membrane filter element is difficult to fix and pressurize, and damage the osmotic membrane. for ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

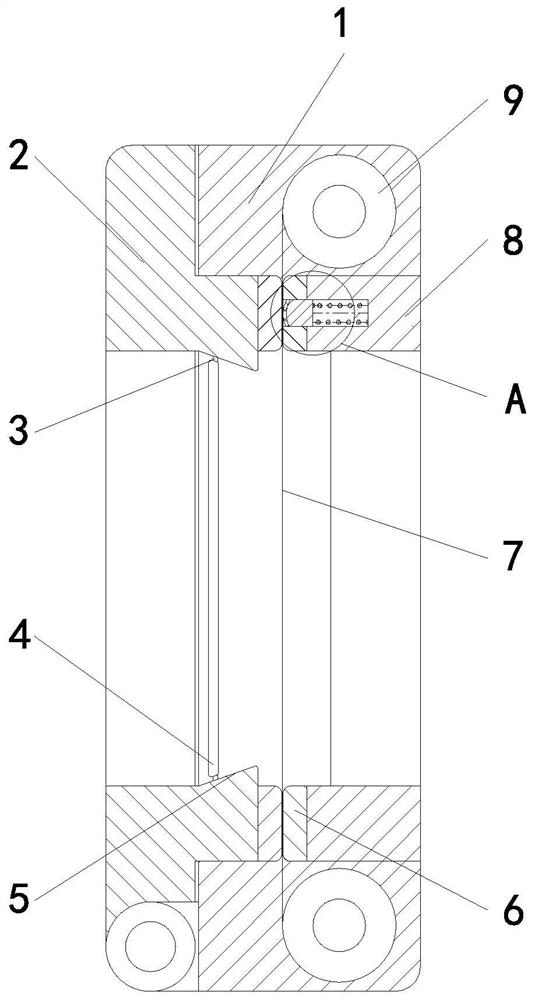

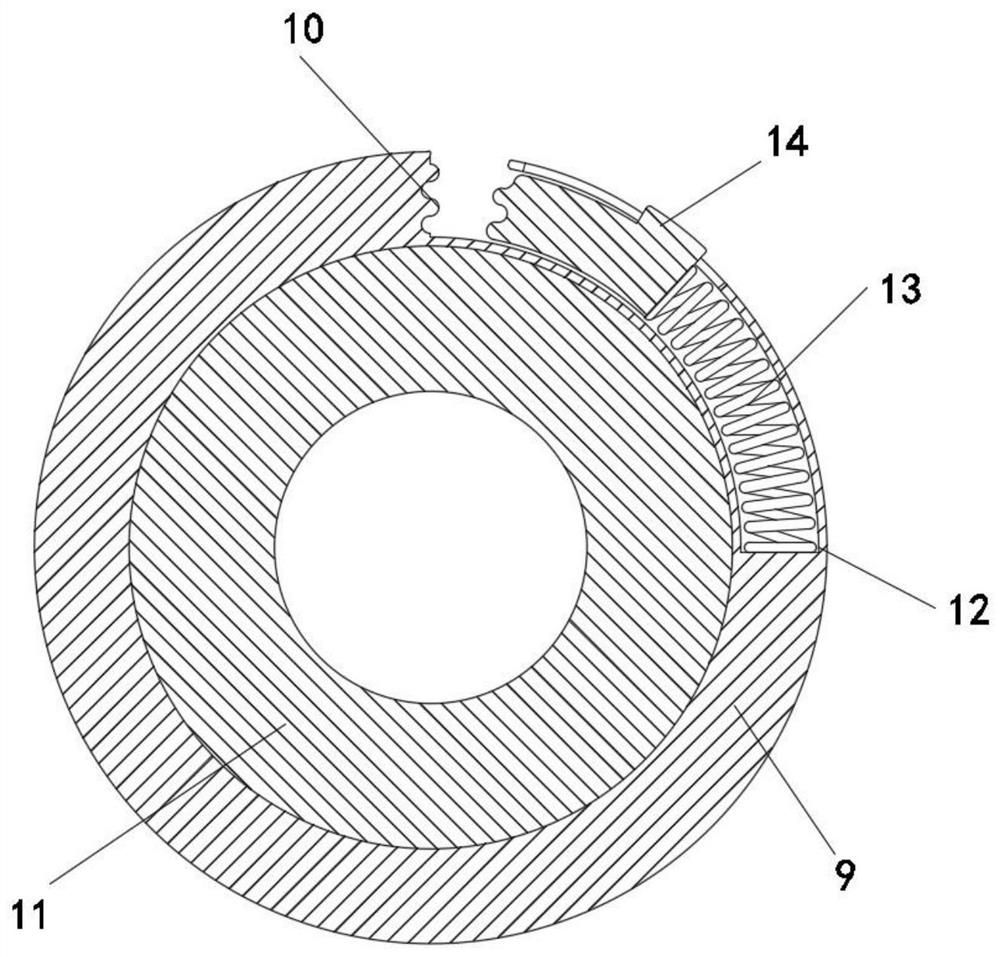

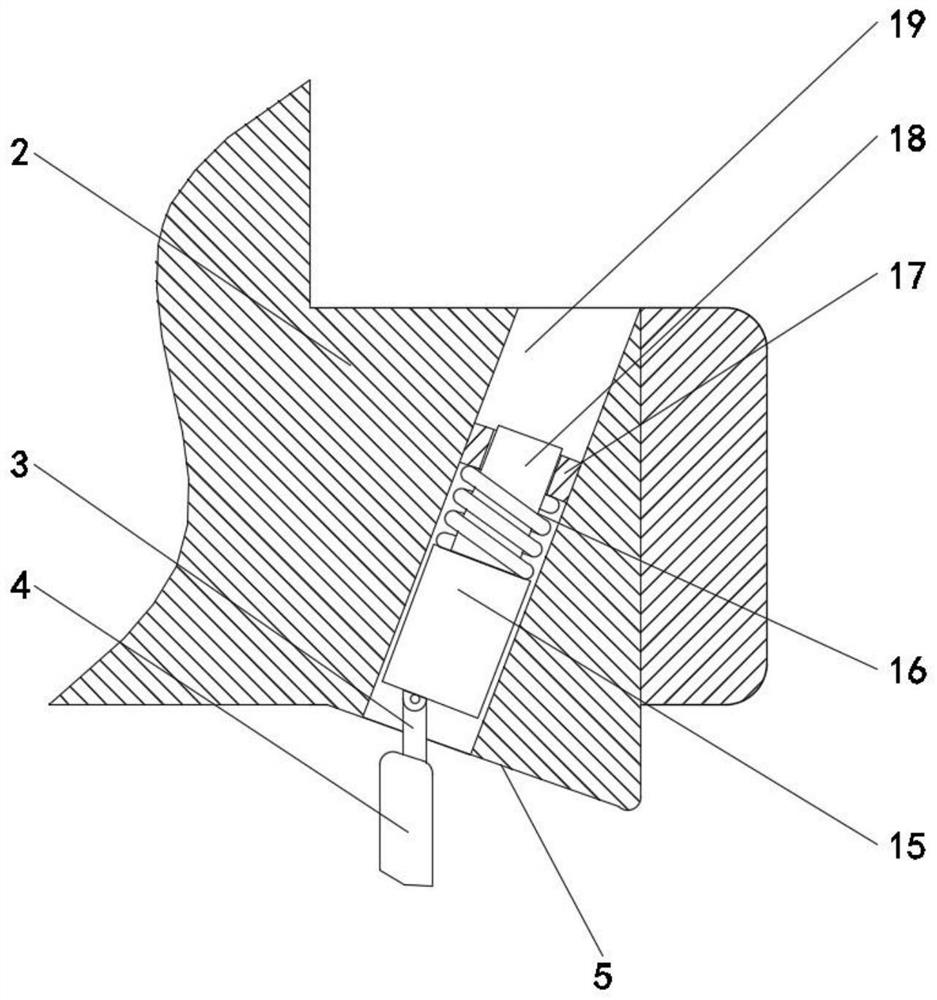

[0029] As an embodiment of the present invention, the first housing 1 is provided with a second pressing plate 8, and a gasket 6 is welded on the side of the second pressing plate 8 close to the second housing 2, and the second housing 2 is close to A gasket 6 is welded on one side of the second pressing plate 8 . During operation, under the joint cooperation of the limit ring 9 and the arc-shaped block 14, the two sides of the permeable membrane 7 are fixed, so that the permeable membrane 7 is kept flat, and the first shell 1 and the second shell 2 are passed through. The rotating shaft rotates so that the adjacent side of the four gaskets 6 clamps the permeable membrane 7, presses the entire permeable membrane 7, and uses the gaskets 6 to fix the permeable membrane 7 in the other two directions, so that the permeable membrane 7 is in use. No water leakage, improve the use effect.

[0030] As an embodiment of the present invention, a set of grooves 20 are formed on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com