A prefabricated building wall with thermal insulation function

A building wall and prefabricated technology, applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of physical and mental damage, insufficient energy saving and environmental protection, etc., and achieve the effect of improving the sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

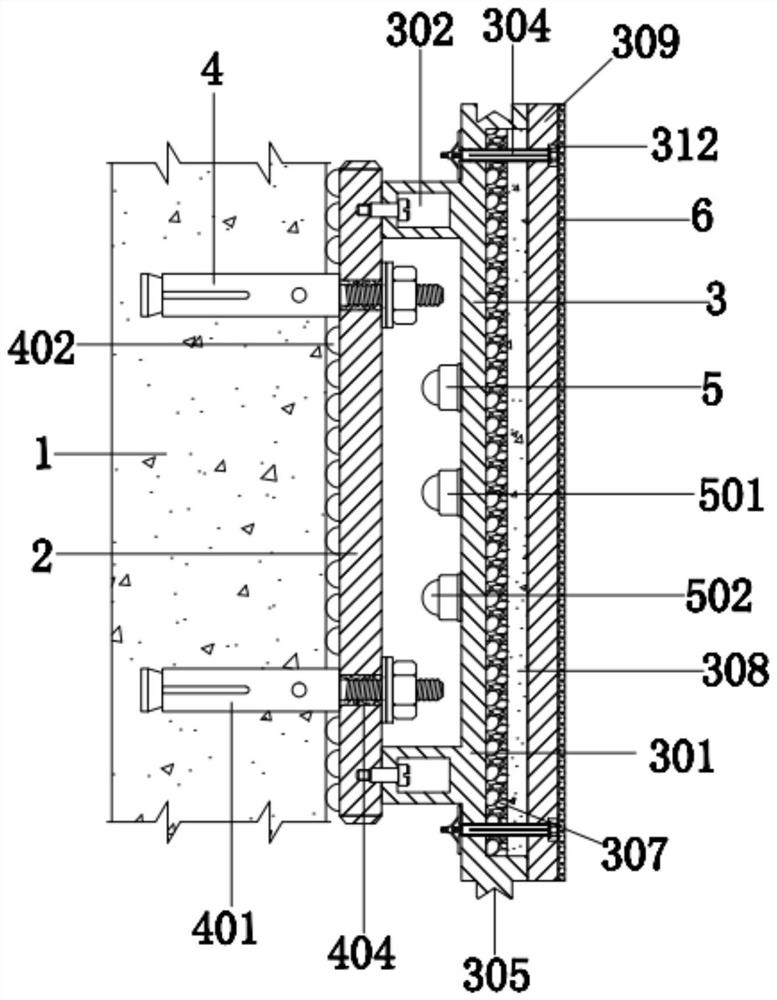

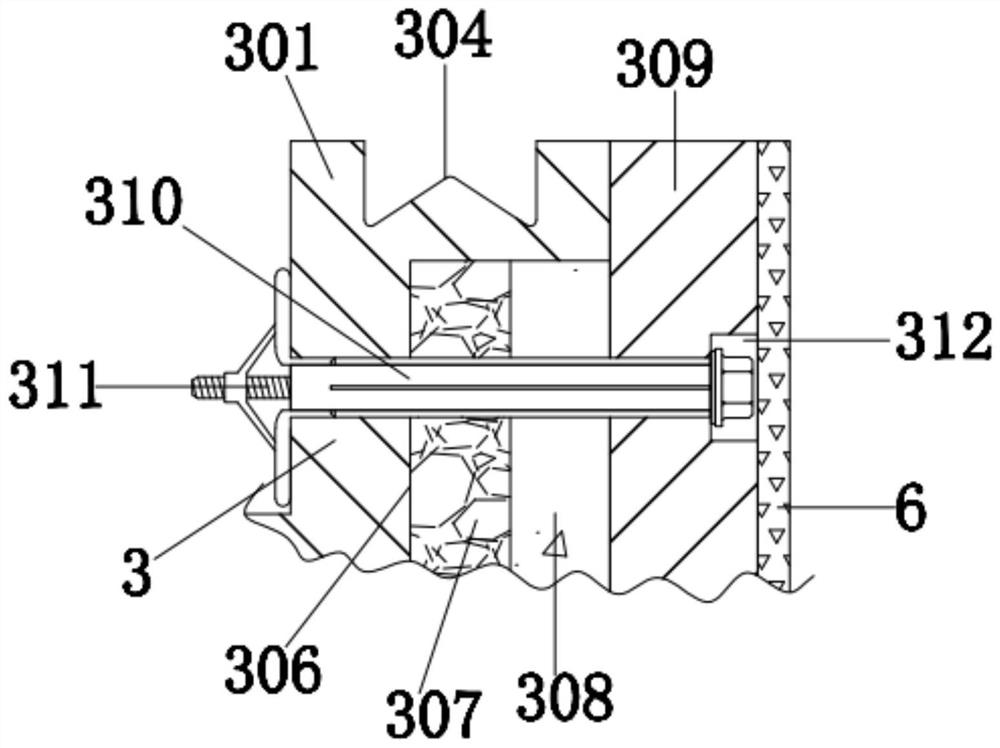

[0041]A prefabricated building wall with thermal insulation function, comprising a base wall 1, the outer surface of the base wall 1 is connected with a keel 2, and the outer surface of the keel 2 is installed with a building decoration wall 3, and the building decoration wall 3 includes a glass magnesium board 301, through groove 302, bolt 303, wedge groove 304, wedge 305, groove 306, insulation layer 307, sound insulation layer 308, decorative plate 309, expansion tube 310, screw 311 and round groove 312, the glass magnesium plate 301 The upper and lower ends of the left surface of the glass magnesium plate 301 are in close contact with the right surface of the keel 2, and the upper and lower ends of the left surface of the glass magnesium board 301 are provided with through grooves 302, and bolts are inserted into the left, front, and rear ends of the inner through groove 302. 303, the bolt 303 runs through the glass magnesium board 301 and is connected to the keel 2 threade...

Embodiment 2

[0043] As an option, see figure 1 , 4 and 5, the prefabricated building wall with thermal insulation function, the keel 2 is connected with the base wall 1 through the connection mechanism 4, the connection mechanism 4 includes expansion bolts 401, rubber balls 402, round holes 403 and rubber cylinders 404, a plurality of rubber balls 402 are fixed on the inner surface of the keel 2 at equal intervals in turn. The rubber ball 402 and the rubber tube 404 are made of silica gel and have a certain toughness. The contact surface of the rubber ball 402 and the foundation wall 1 is tight. 403 are respectively set on the upper and lower sides of the right surface of the keel 2, the inner wall of the round hole 403 is fixed with a rubber tube 404, and the inside of the two rubber tubes 404 is provided with an expansion bolt 401, and the expansion bolt 401 connects the keel 2 to the foundation wall 1 , a plurality of rubber balls 402 are evenly distributed on the inner surface of the ...

Embodiment 3

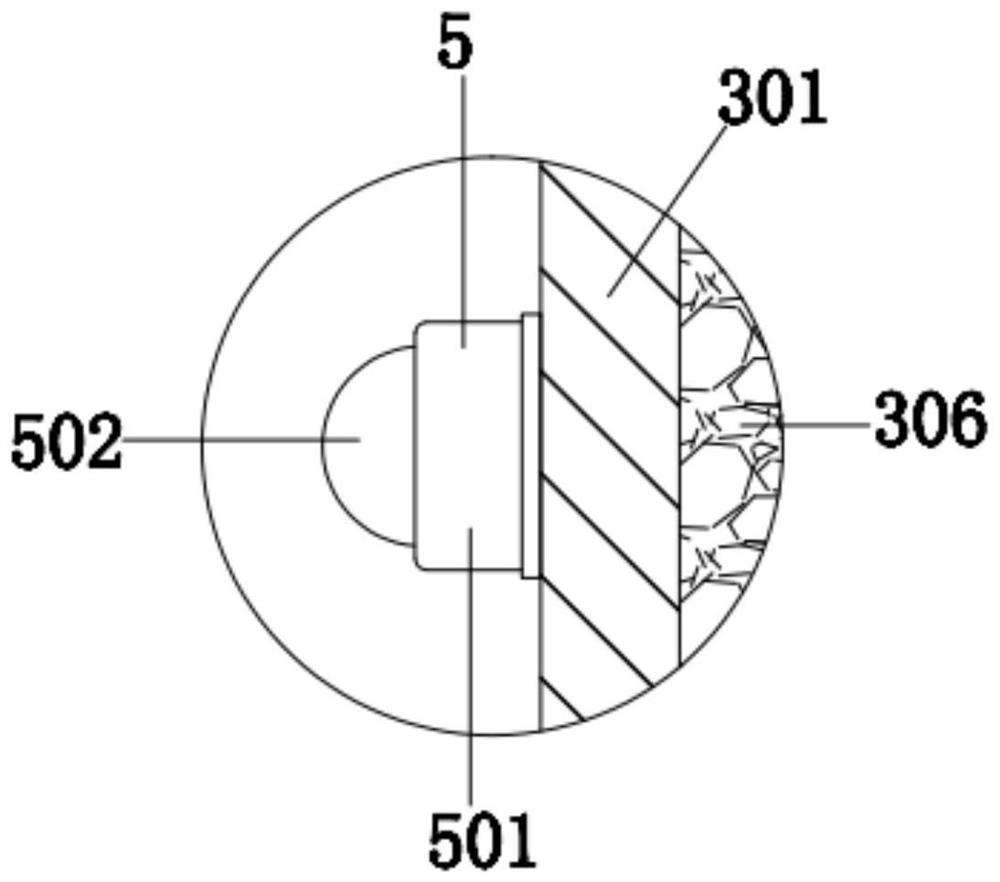

[0046] As an option, see figure 1 with 3 , a prefabricated building wall with thermal insulation function, the center of the inner surface of the glass magnesium board 301 is provided with a fire suppressing mechanism 5, the fire suppressing mechanism 5 includes a block 501 and a fire extinguishing ball 502, and a plurality of blocks 501 are evenly and equidistantly fixed on the At the center of the left surface of the glass magnesium board 301, the other side of the block 501 is clamped with a fire extinguishing ball 502. The fire extinguishing ball 502 is composed of a foam shell, a built-in dry powder driving device, and an ABC dry powder fire extinguishing agent. The outside of the fire extinguishing ball device is wound with a cross-shaped lead wire. When the external lead wire is ignited, the driving medium is activated, and the inside of the shell expands and ruptures rapidly. It is extinguished under the dual action of physics and chemistry of dry powder fire extingui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com