A plugging structure and construction method for the lower port of branch roadway

A technology of port and roadway, which is applied in the field of plugging structure and construction of the port under the branch road, which can solve the problems of affecting safety production, long time consumption, and heavy labor, so as to ensure the impact resistance and stability, and avoid the deformation of the plugging structure , The effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In the continuous mining and charging process, the lower port of the branch road needs to be blocked, the sealing mechanism of the lower port of the branch road needs to ensure the sealing and stability, and the lower port of the branch road needs to be quickly blocked.

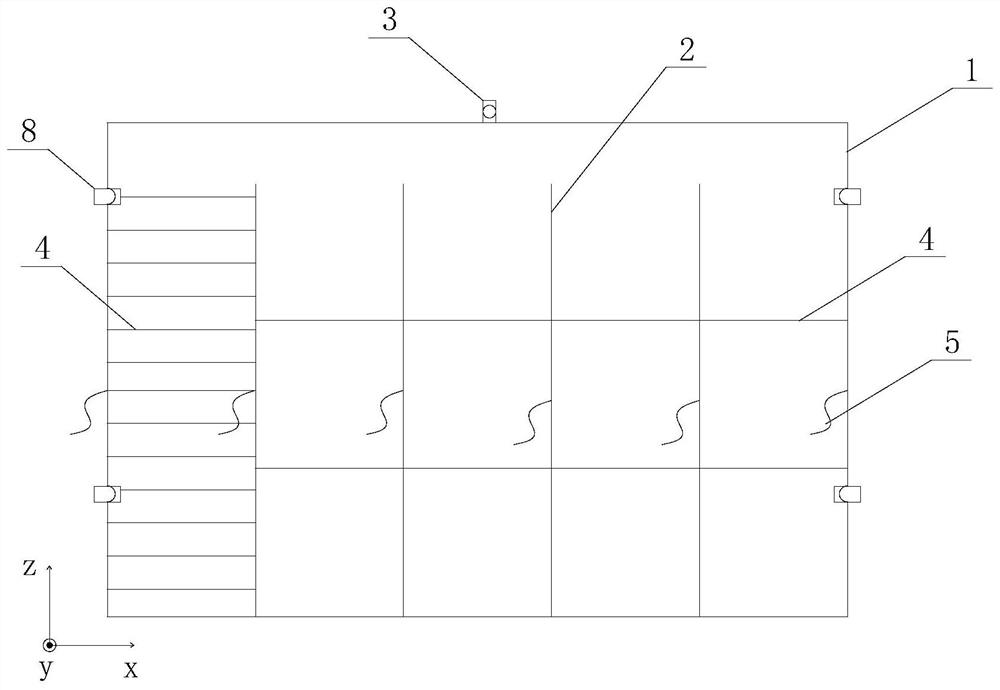

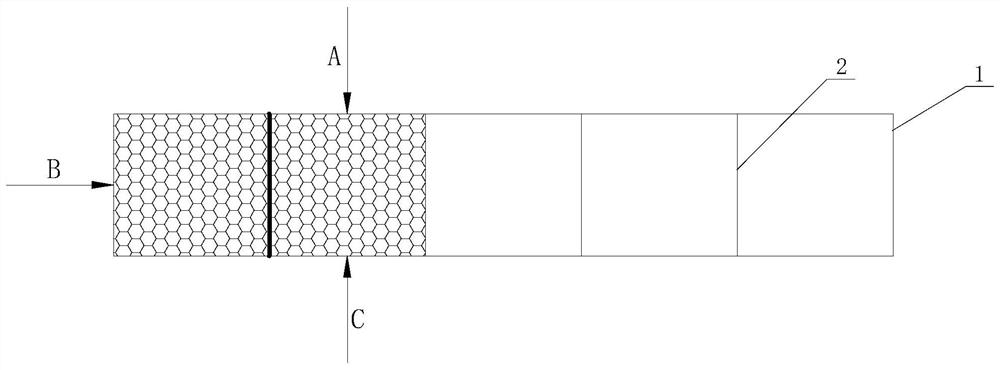

[0045] A plugging structure for the lower port of a branch road, which is provided with an isolation cloth in the mold bag, the isolation cloth extends from the lower edge of the mold bag along the second direction and the third direction, the isolation cloth and the mold bag are closely connected, and the mold bag The space inside the bag is divided into multiple sections along the first direction. Wherein the mold bag can be made of nylon fiber cloth, and the nylon fiber cloth is also provided with a waterproof layer, and the isolation cloth and the mold bag can be made of the same material. The upper edge surface of the mold bag is connected with the roadway roof, and the lower edge surface is conne...

Embodiment 2

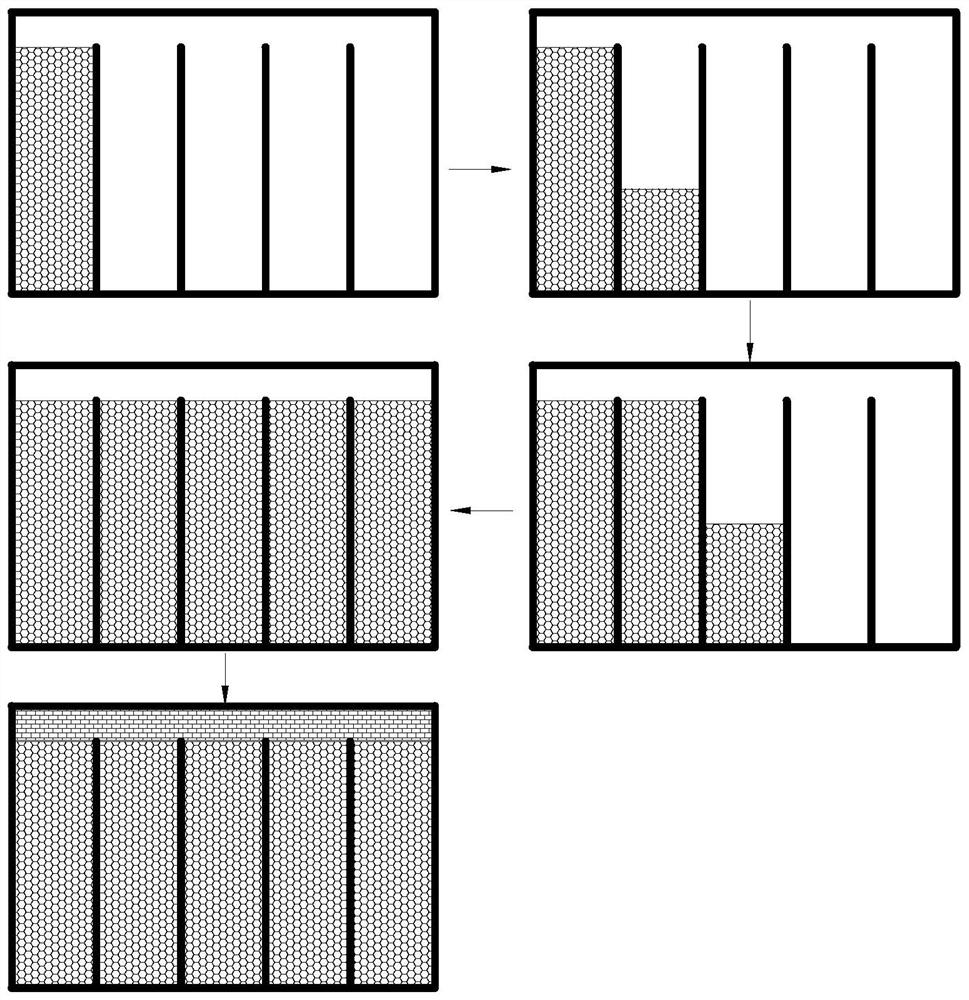

[0056] A plugging structure for the lower port of a branch road. An isolation cloth is arranged in the mold bag, and the isolation cloth extends from the lower edge of the mold bag along the second direction and the third direction, and divides the space inside the mold bag into multiple sections along the first direction. There is an interval in the third direction between the upper edge surface of the mold bag and the upper end of the isolation cloth, a fixing part is arranged on the outer side of the mold bag, and an exhaust hole is also arranged on the mold bag. Reinforcing ribs are also arranged in each segment on the mold bag. Wherein the inside of the mold bag can be provided with 5 segments, or more segments, and the grouting port is arranged on the upper part of the 1st segment, the 3rd segment and the 5th segment, that is, respectively on the two sides of the first direction. Set grouting ports at the two ends and in the middle; thus, grouting can be performed first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com