Combined embedded sleeve pipe

A combined, pre-embedded technology, applied in the direction of pipes, pipes/pipe joints/pipes, adjustable connections, etc., can solve the problems of affecting construction quality, easy confusion, and increasing installation difficulty, so as to solve the on-site welding process and save construction. cost, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

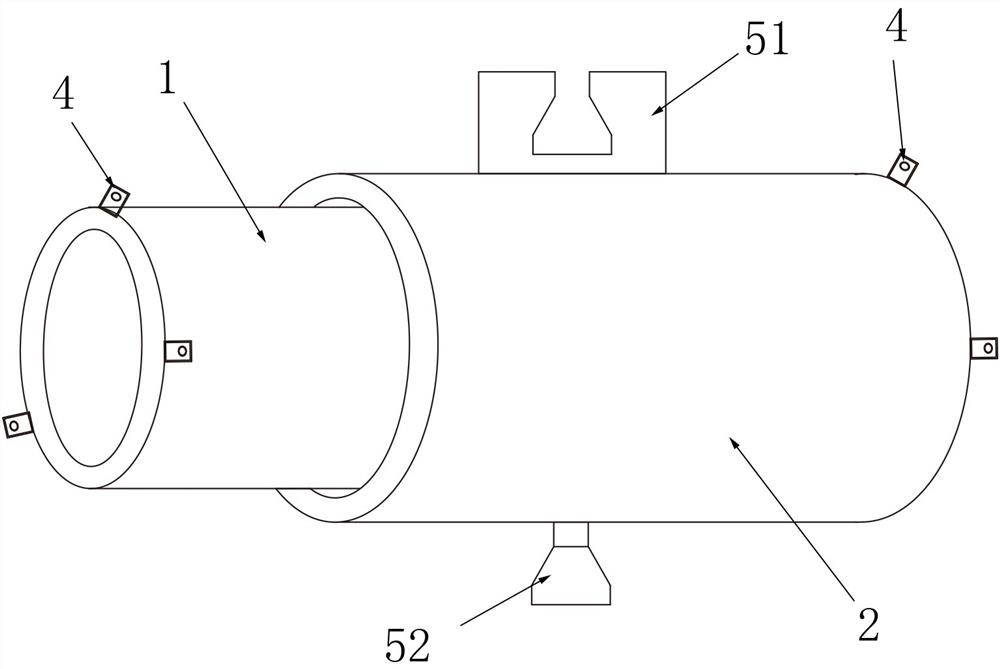

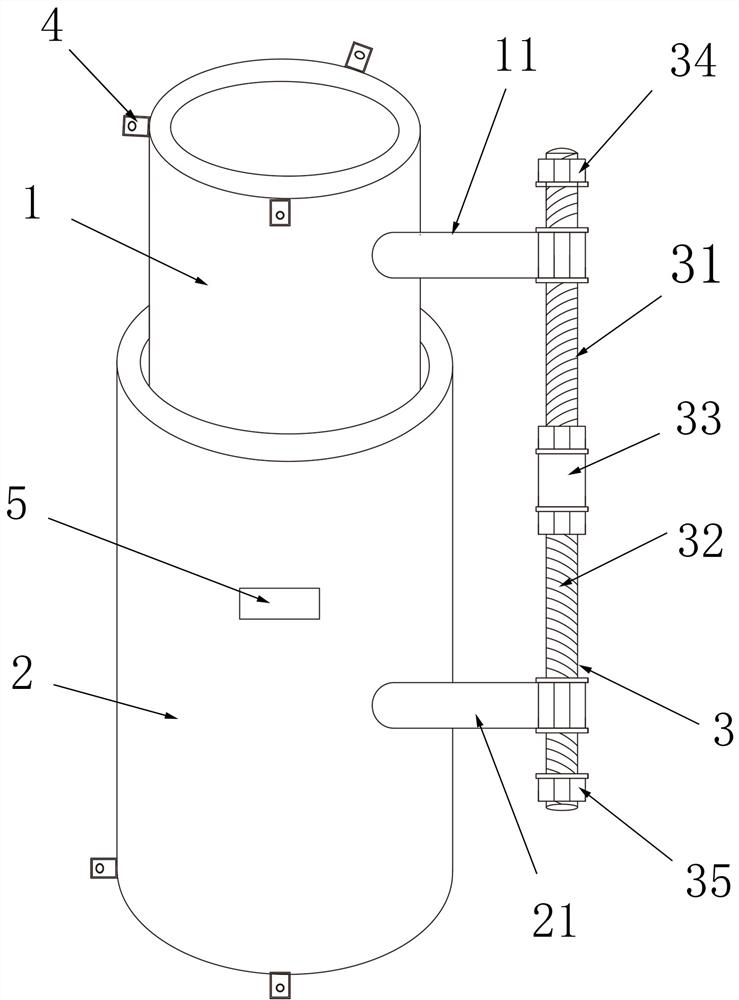

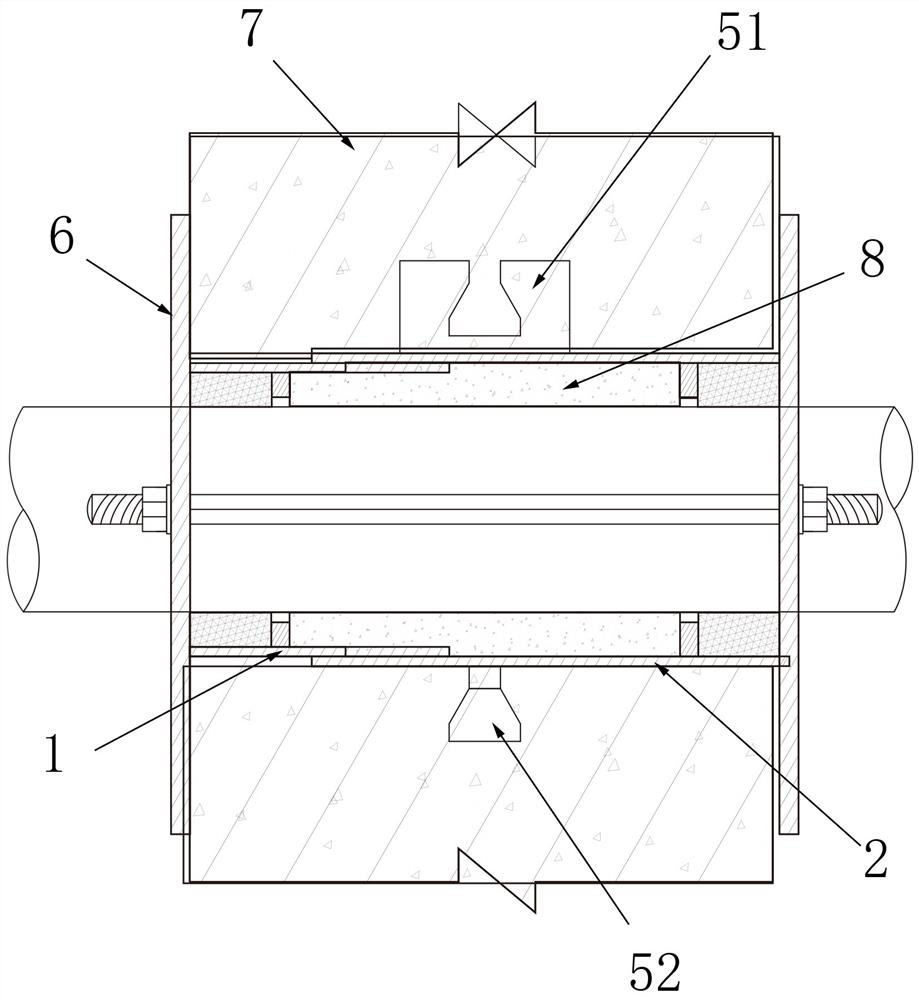

[0016] See attached picture. The embedded casing described in this embodiment includes an inner tube 1 and an outer tube 2 which are coaxially arranged. The inner tube 1 is placed inside the outer tube 2, and the gap between the two is not more than 3 mm; the inner tube 1 is on the outer circumference A first mounting rod 11 is fixed, and a second mounting rod 21 is fixed on the outer circumference of the outer tube 2, and the ends of the first and second mounting rods are provided with screw holes; it also includes a screw 3 with a hexagonal connecting block 33 in the middle of the screw. The screws at both ends of the hexagonal connecting block are respectively provided with a forward thread 31 and a reverse thread 32. The first mounting rod 11 on the outer side of the inner tube is threaded with one end of the screw 3 through the screw hole, and the second mounting rod 21 on the outer side of the outer tube passes through The screw hole is threaded with the other end of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap