Low temperature electrical heating heat exchange device

A heat exchange device and electric heating technology, which is applied in the direction of heat storage heaters, fluid heaters, heat exchangers, etc., can solve the problems of large volatilization and waste of heat exchange media, uneven heating of heat exchange media, and large dimensions , to achieve the effect of reducing the overall size and improving the utilization rate of the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

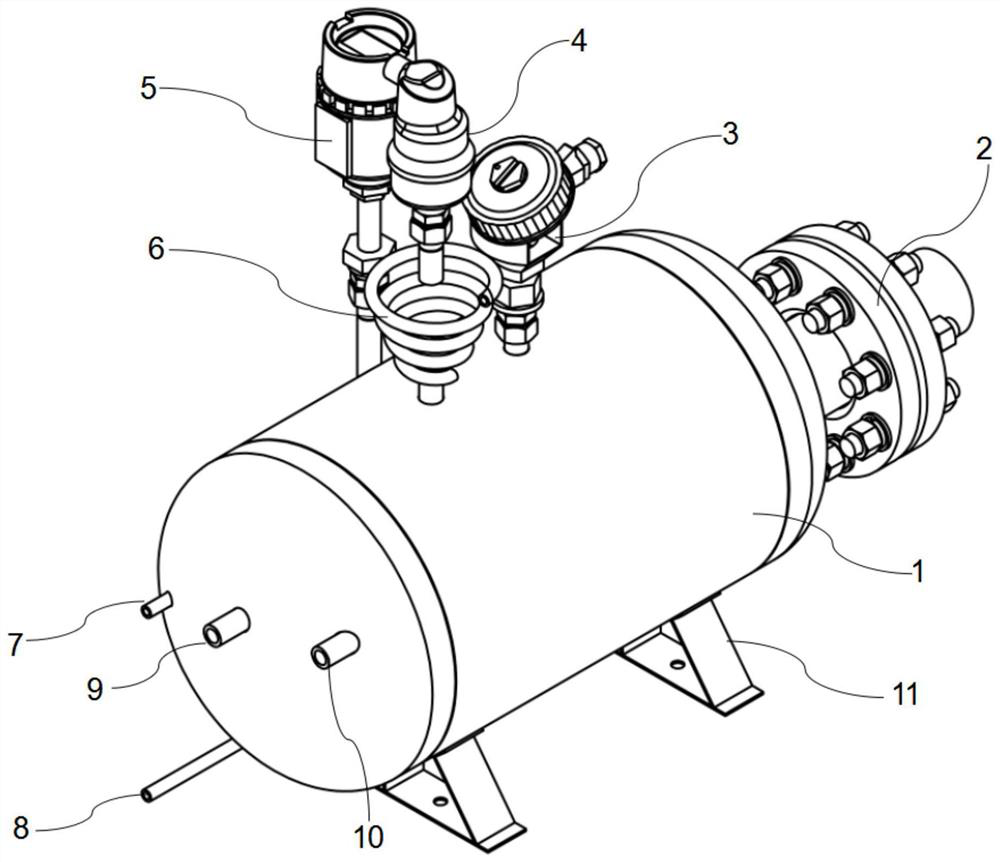

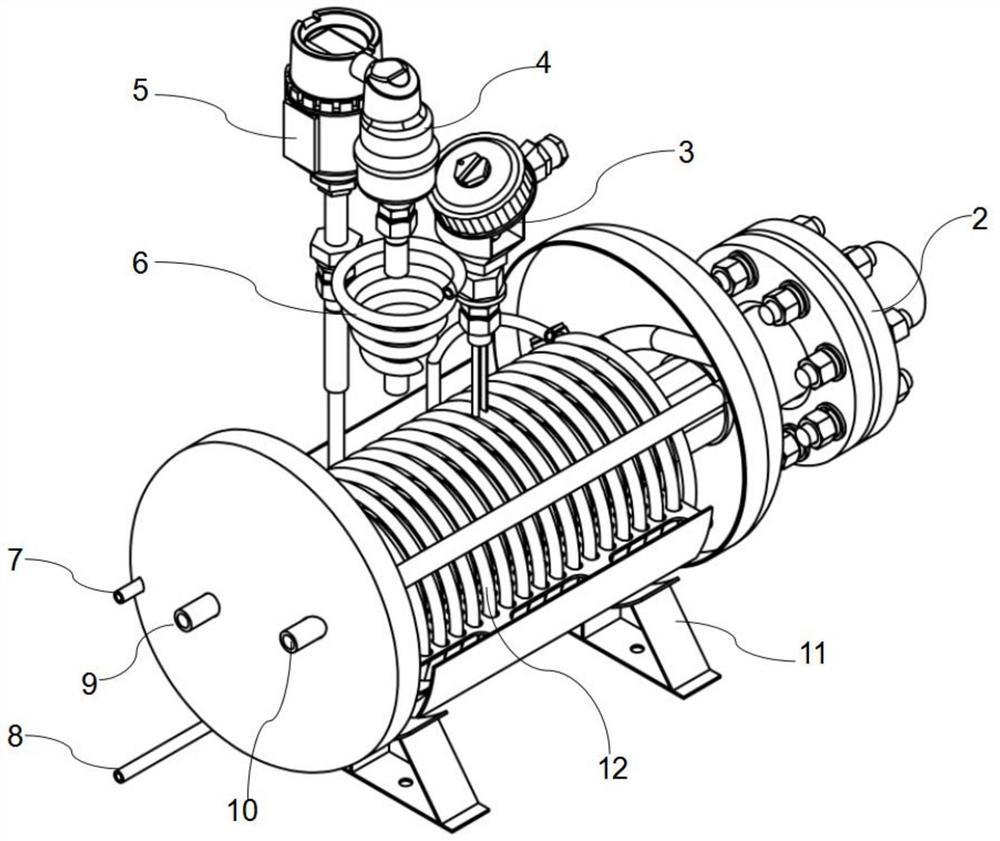

[0035] In this embodiment, a low-temperature electric heating heat exchange device is specifically disclosed, which is mainly composed of an electric heating rod 2, a heat exchanger shell 1, a coil group 12, a liquid level gauge 3, an automatic discharge valve, and a temperature transmitter 5 and other components, in order to be able to realize the gasification or heating function of the low-temperature medium, the specific design is as follows:

[0036] like figure 1 , figure 2 As shown, the heat exchanger shell 1 is used as the carrier of the device and the heat exchanger shell 1 is set in a cylindrical shape. Preferably, the heat exchanger shell includes a cylindrical body and elliptical heads that are hermetically fitted at both ends of the cylindrical body, and the coil group is placed on the central axis of the cylindrical body or below the central axis. The top of the body is equipped with an automatic exhaust valve, a liquid level gauge and a temperature transmitter...

Embodiment 2

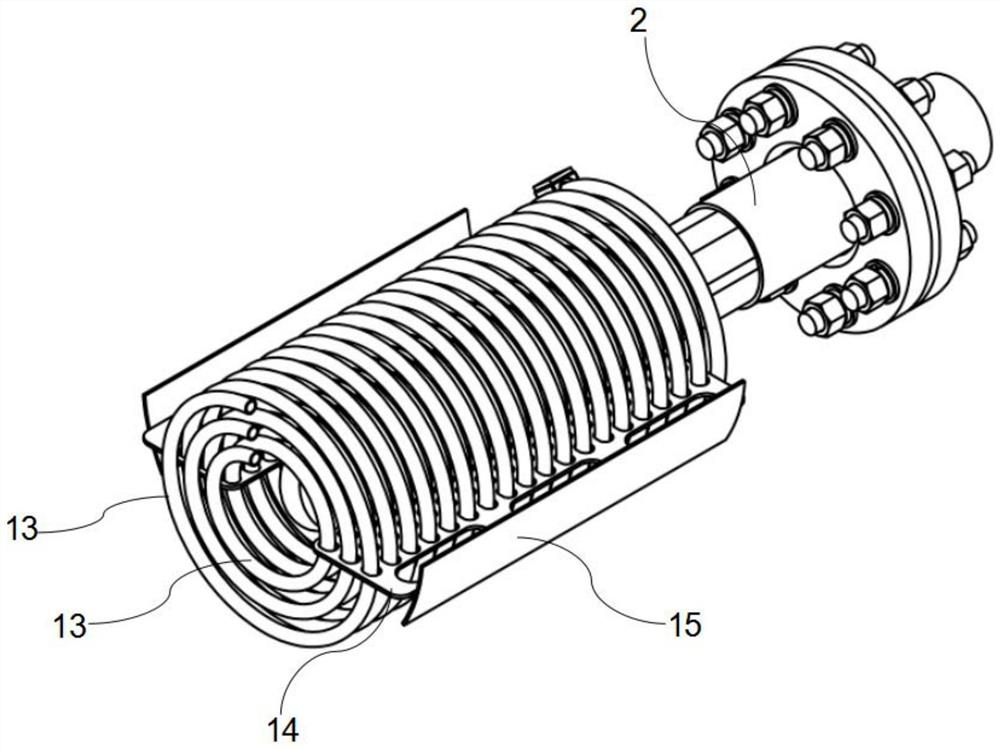

[0047] On the basis of Embodiment 1, in order to realize that the coil group 12 is firmly installed inside the heat exchanger housing 1, to ensure the normal operation of the coil group 12, as image 3 , Figure 4 as well as Figure 5 As shown, it also includes a fixing plate 14 arranged in the heat exchanger shell 1, and a plurality of fixing holes 17 are opened on the fixing plate 14, and each fixing hole 17 is arranged along the column direction and the row direction, and is located in the same column Each fixing hole 17 in the direction corresponds to each layer of coiled tubes 13 respectively, and each fixing hole 17 in the same row direction matches the spiral shape of the same layer of coiled tubes 13 respectively. In this embodiment, three layers of coils 13 are arranged and the distances between adjacent two layers of coils 13 are equal. On the fixing plate 14, a There are three rows of fixing holes 17 (the row is the axial direction of the heat exchanger shell 1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com