Fatigue-stress relaxation test device for prestressed tendons

A prestressed tendon and stress relaxation technology, which is applied in the field of prestressed tendon material testing, can solve the problems of large time and effort, difficult to consider the performance changes of rebar materials, and high cost, so as to achieve the effect of improving accuracy and guiding design specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

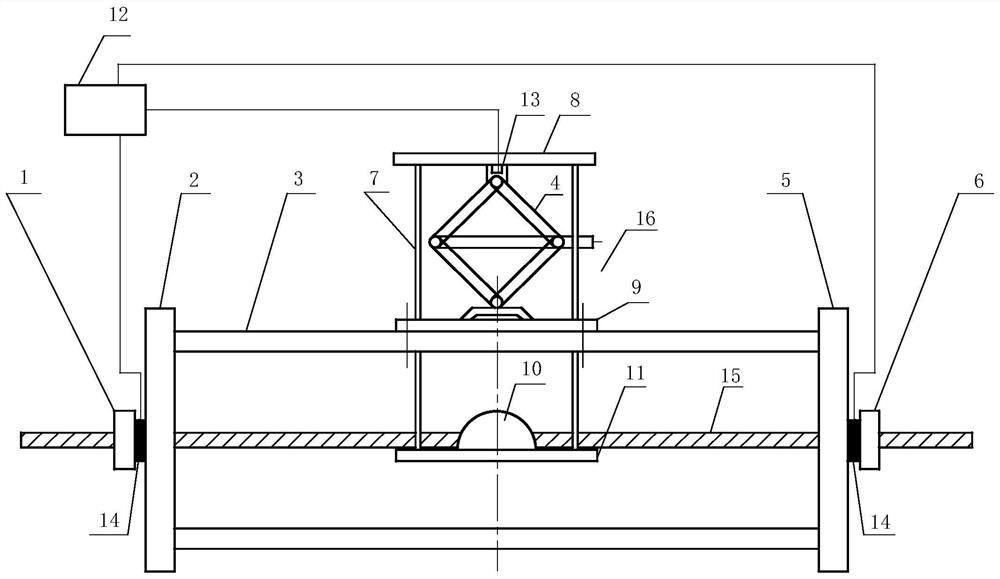

[0019]Such asfigure 1As shown, the fatigue-stress relaxation test apparatus of the prestressed rib of the present invention includes: left anchor 1, left side plate 2, support rod 3, right side plate 5, right anchor 6, load bracket 16, jack 4 However, the data acquisition instrument 12, the force sensor 13, and the stress sensor 14, the left side panel 2 and the right side plate 5 are respectively fixed at both ends of the four support rods 3, and both ends of the four support rods 3 are uniformly fixed to the left. On the periphery of the side panel 2 and the right side plate 5, the reinforcement 15 is passed through the left side plate 2 and the right side plate 5, and the left anchor 1 and the right anchide 6 are fixed to the left side plate after stretching at both ends. 2 and the right side plate 5, between the left anchor 1 and the left side plate 2 and the right anchor 6 and the right side plate 5 are equipped with stress sensor 14, respectively, to be dense 15 is a high stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com