Wire penetration piece for high-temperature and high-pressure electrochemical corrosion experiment, and assembling method thereof

A high-temperature, high-pressure, corrosion experiment technology, applied in electrical components, cable entry sealing devices, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of sealing, harsh cooling, high temperature requirements, etc., to ensure stability and improve durability High-temperature performance and the effect of ensuring convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

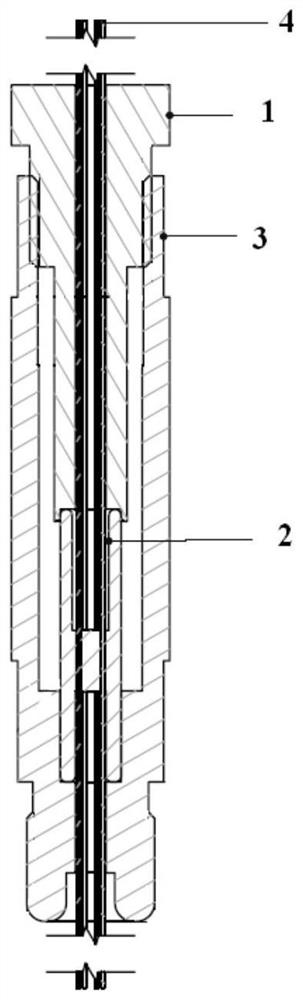

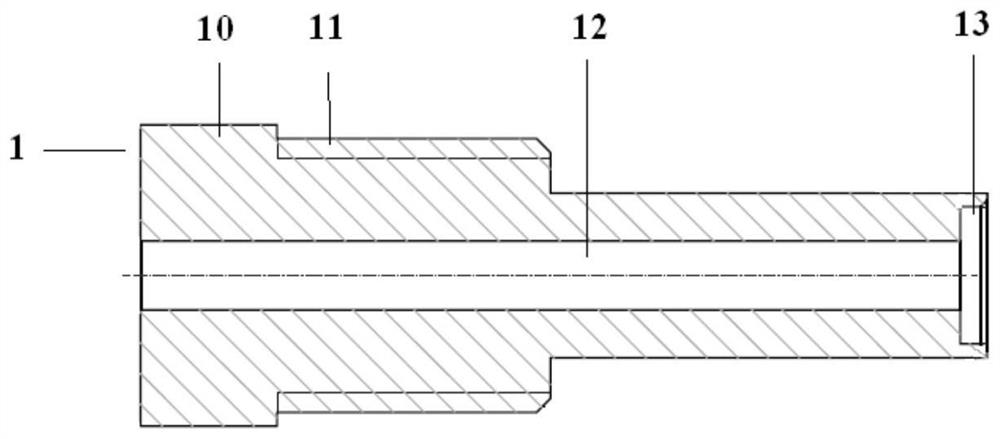

[0044] Such as Figure 1-Figure 6 As shown, a wire penetration for high temperature and high pressure electrochemical corrosion experiments, including a compression rod 1, a sealing joint 2, a cooling jacket 3 and a threaded adapter;

[0045]The cooling jacket 3 is a hollow structure, the cooling jacket 3 is provided with a cooling water chamber 32, the side wall of the cooling jacket 3 is provided with a cooling water pipe 31 communicating with the cooling water chamber 32, and the lower end of the cooling jacket 3 is threaded. The adapter is sealed and connected to the autoclave. Specifically, the outer wall of the lower end of the cooling jacket 3 is provided with a mounting thread 35 that matches the threaded adapter. The threaded adapter includes a nut 5 and a screw rod 6, and the nut 5 is a hollow structure. The screw rod 6 is a central equal-diameter through hole structure, and the outer wall of the middle part of the screw rod 6 is provided with a protruding platform, ...

Embodiment 2

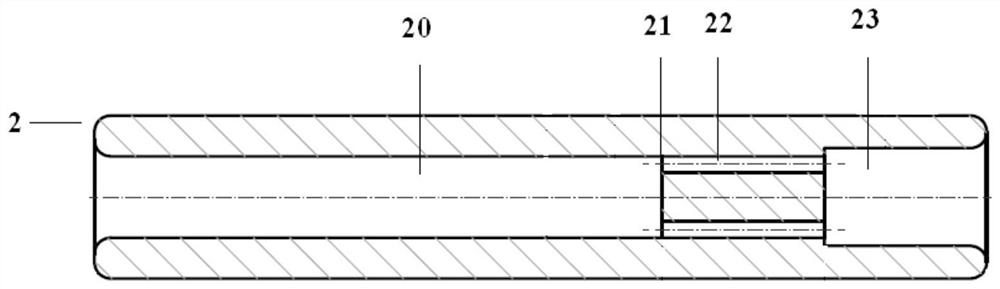

[0052] Such as Figure 1-Figure 7 As shown, this embodiment is based on Embodiment 1, and also includes a heat-shrinkable tube 40 and a high-temperature-resistant ceramic tube 42 that cooperate with the electrode lead 4, and the high-temperature-resistant ceramic tube 42 is arranged on the electrode lead 4 below the sealing point 41, so The electrode wire 4 is provided with a heat-shrinkable tube 40 above the sealing point 41; the sealing joint 2 is provided with a cooling through hole 20 below the platform 21, and the sealing joint 2 is provided with a sealing channel 23 above the platform 21. The sealed tunnel 23 is filled with a metal sealant, and the metal sealant is a high temperature resistant polymer composite resin.

[0053] In this embodiment, the metal sealant is used to seal the sealing channel 23: the sealing material used is a high temperature and high pressure metal sealant, preferably, a high temperature resistant polymer composite resin structure sealant is sel...

Embodiment 3

[0057] This embodiment is based on Embodiment 1. The cooling jacket 3 is provided with a sealing joint slot 33 below the cooling water cavity 32, and the bottom of the sealing joint 2 is clamped in the sealing joint slot 33, and then the sealing joint 2 The side wall of the lower end is sealed and connected with the cooling water cavity 32; the center of the pressing rod 1 is provided with a wire through hole 12, and the inside of the pressing rod 1 is provided with a groove 13 below the wire through hole 12, and the sealing joint 2 The top is embedded in the groove 13, and the upper end sidewall of the sealing joint 2 is in sealing connection with the compression rod 1.

[0058] The arrangement of the sealing joint groove 33 and the groove 13 can improve the installation stability of the sealing joint 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com