Recoverable direct current method electrode installation device and segment monitoring method in long boreholes

A direct current method and long drilling technology, which is applied in the field of engineering geophysical exploration, can solve the problems of special operating environment that cannot be applied to explosion-proof requirements, large loss of electrode cables, low drilling efficiency, etc., and saves grouting and solidification time. , Improve the monitoring accuracy and reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

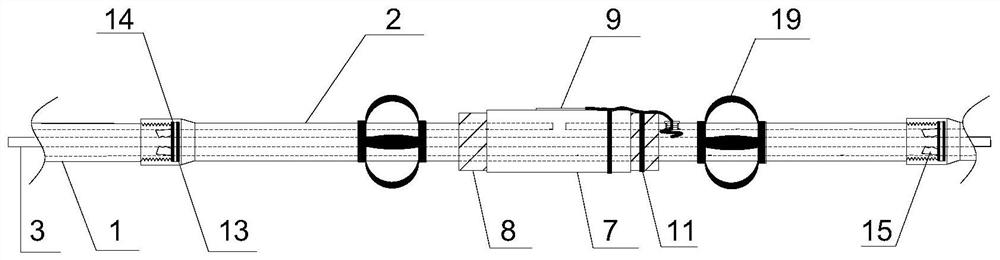

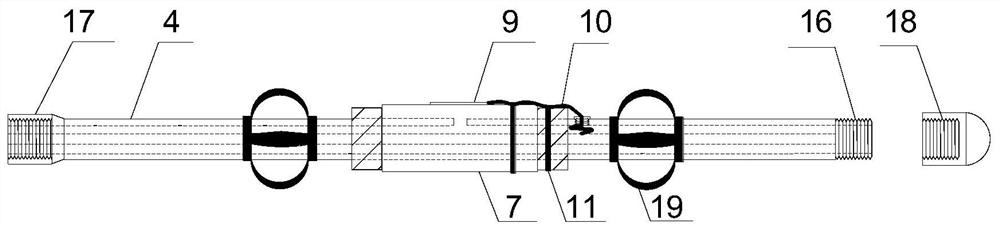

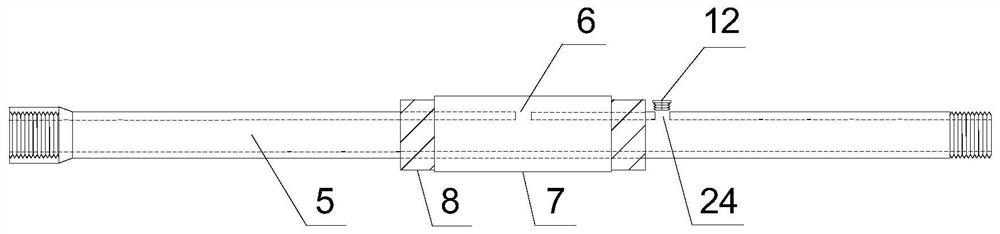

[0044] Such as Figure 1 to Figure 5 As shown, the present invention provides a recyclable direct current method electrode installation device in a long borehole, which includes a push tube 1 , a load module 2 and a multi-core cable 3 .

[0045] The push tube 1 is a hollow insulating rigid tube with internal threads 17 and external threads 16 at both ends. The material of the push tube 1 is high-strength insulating material, which is resistant to pulling and torsion.

[0046] The pole loading module 2 includes a single-way expander 4, an electrode plate 9, an elastic centralizer 19, and a cable tie 11. The single-way expander 4 includes a single-way tube 5, an expansion capsule 7 and an encapsulation ring 8. The expansion capsule 7 is sealed in the middle of the outer side of the one-way tube 5 by two encapsulation rings 8; the one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com