Secondary puffed spicy strip and making method thereof

A technology of secondary puffing and spicy strips, which is applied in the field of food processing, can solve the problems of not easy to fix oil, too small pores of spicy strips, serious loss, etc., and achieve the effect of increasing solid oil rate, complete starch gelatinization, and large expansion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

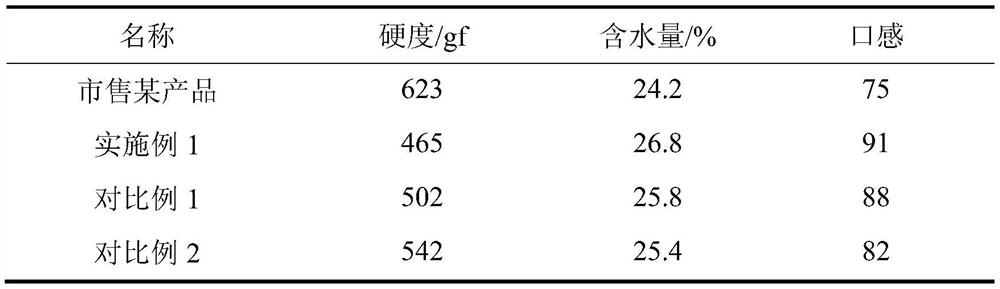

Examples

Embodiment 1

[0026] This embodiment provides a secondary puffed spicy strips and a preparation method thereof, the preparation method comprising:

[0027] S1: Primary expansion: Mix low-gluten wheat flour, mannitol and lactitol evenly, and then extrude and expand to obtain raw material powder after primary expansion; The powder feeding speed after the powder is fully expanded is 1.8kg / min;

[0028] S2: crush the raw material powder after primary expansion until passing through a 60-mesh sieve;

[0029] S3: secondary puffing: the raw material powder obtained after step S2 is pulverized, mixed evenly with edible salt, monoglyceride and water, and then extruded and puffed to obtain a semi-finished spicy bar billet; the condition of extrusion puffing is: the speed at which the powder is started 0.5kg / min, and the powder feeding speed after the raw material powder is fully expanded is 1.8kg / min;

[0030] Relative to the total weight of raw material powder, edible salt and monoglyceride, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com