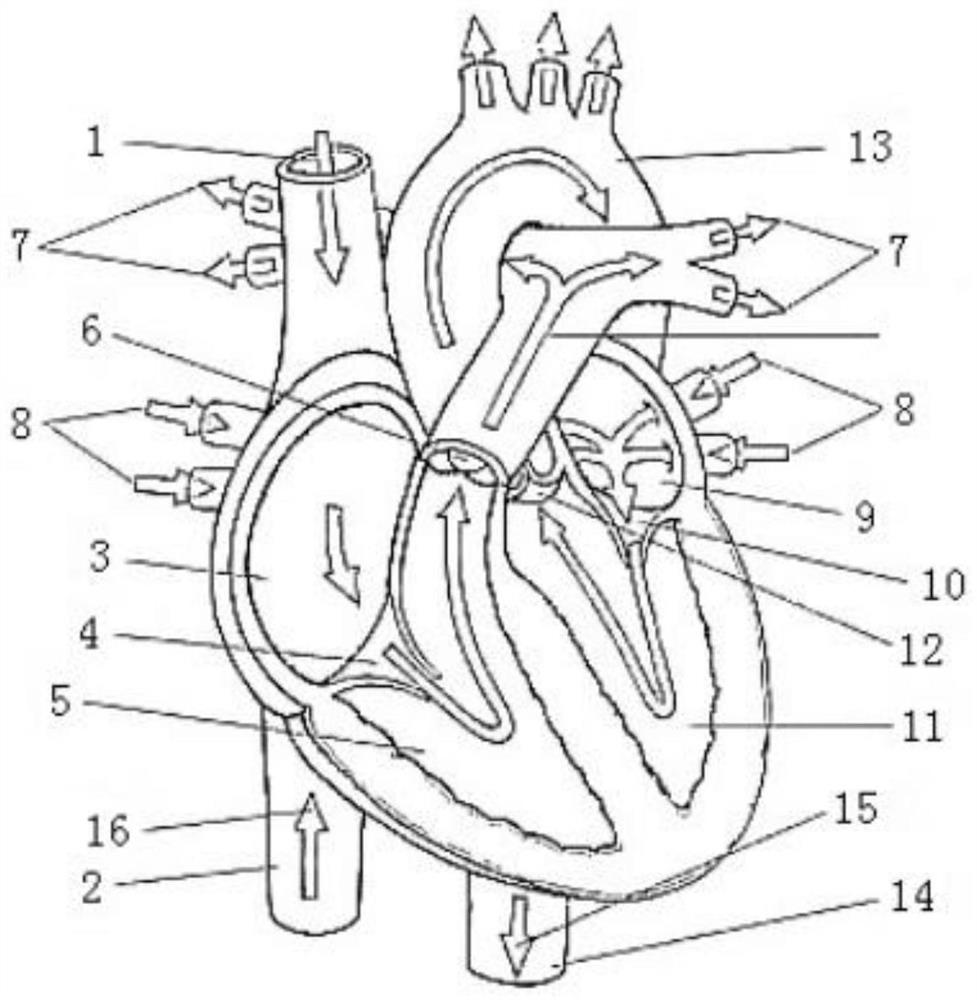

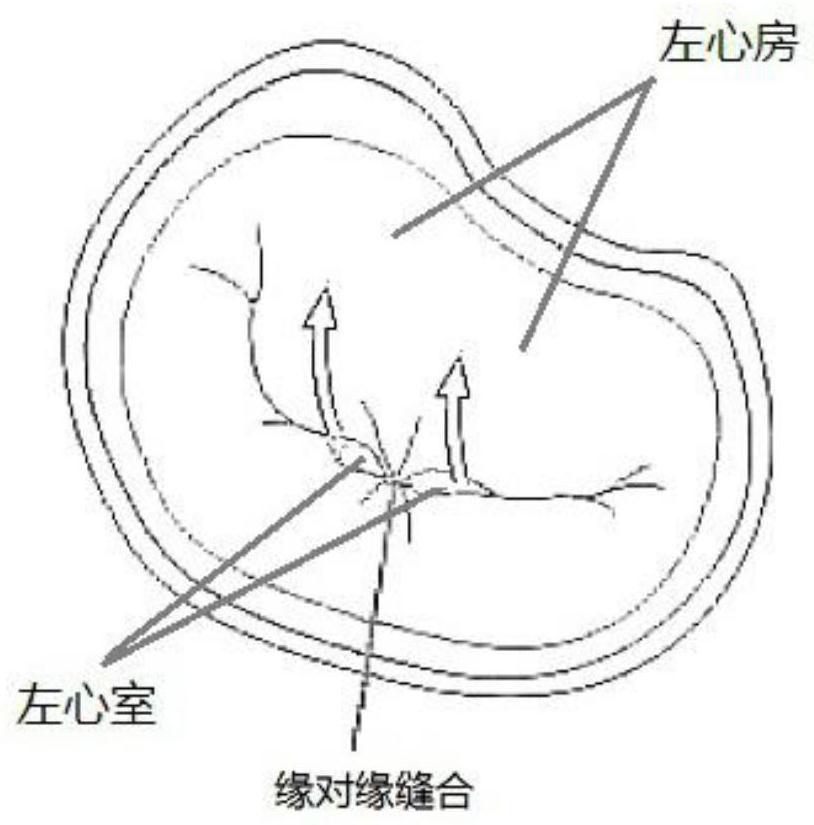

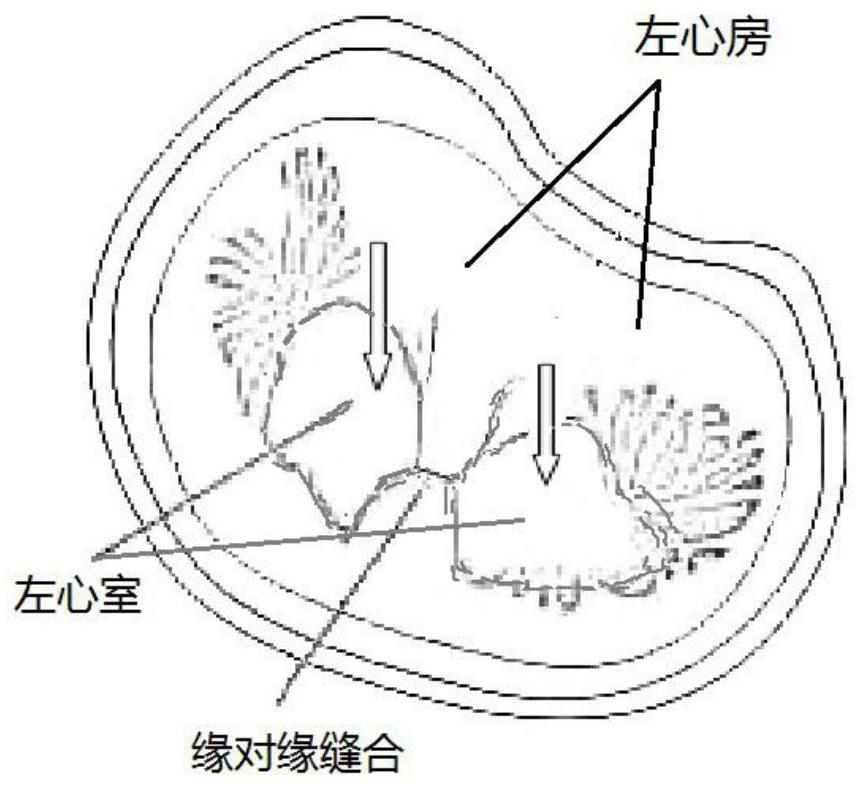

Compressible valve clamping device and clamping system thereof

A valve and slider technology, applied to the heart valve, valve annulus, etc., can solve the problems that the clamp is a rigid material that cannot be compressed and transported, easy to damage the atrial roof, easy to wind the chordae tendineae, etc., so as to reduce the risk of thrombosis , reducing the risk of injury, the effect of small operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0095] 1) Assembly of the push rod 120, the delivery tube 110 and the loader 100: from the far end of the push rod 120, the push rod 120 is inserted into the fourth through hole from the proximal end of the delivery tube 110, and then from the far end of the delivery tube 110 passing the delivery tube 110 from the proximal end of the loader 100 into the third through hole;

[0096] 2) Assembly between the slide block 30 and the delivery pipe 110: as Figure 8a and 8b As shown, after matching the position of the clamping hole 1104 on the extension arm 1101 of the delivery tube 110 with the protrusion 305 on the slider 30, the push rod 120 is pierced in the fourth through hole of the delivery tube 110, and it is ensured that the push rod 120 simultaneously Through the hole 1103 of the clamping member 1102, the extension arm 1101 in the flaring state is narrowed and restricted, so that the protrusion 305 just fits into the clamping hole 1104;

[0097] 3) Assembly between the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com