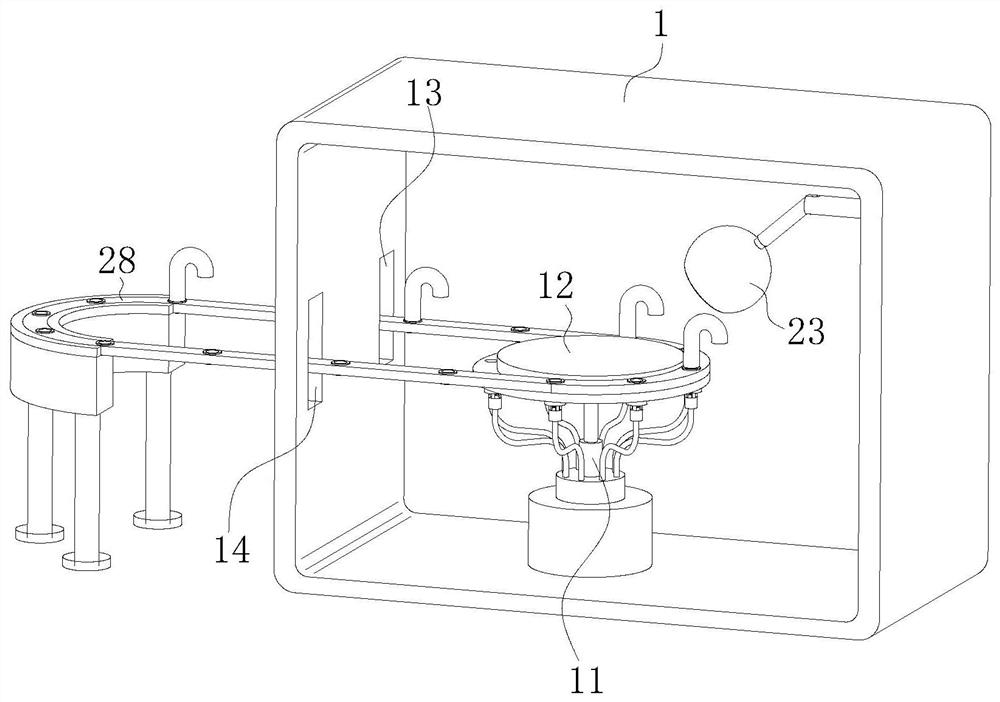

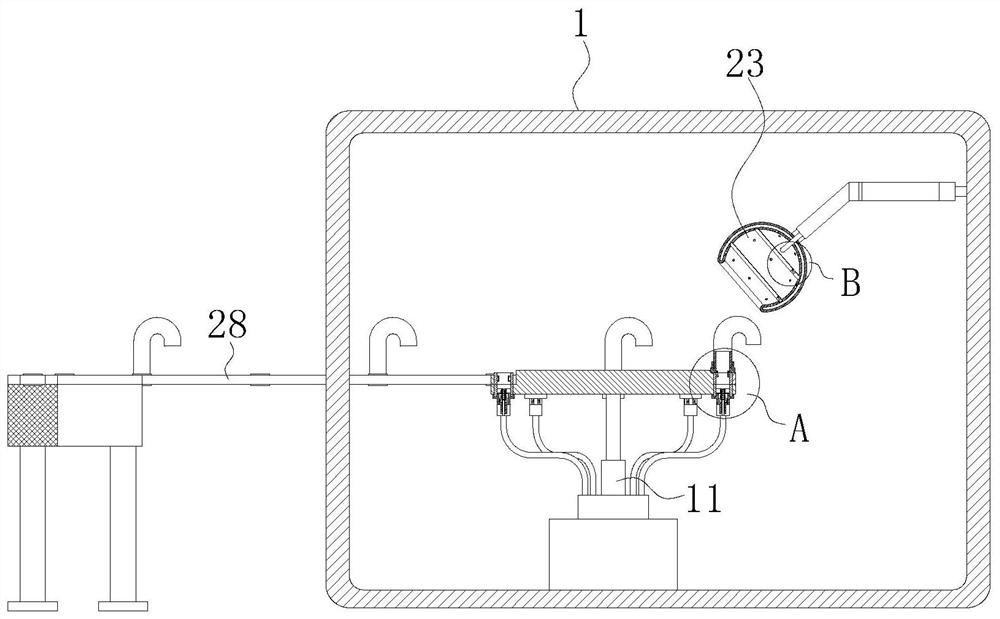

Pneumatic numerical control shot blasting machine

A shot blasting machine, pneumatic technology, applied in the direction of abrasive jet machine tools, spray guns, metal processing equipment, etc., can solve the problems of inability to stretch, unable to eliminate the stress of the elbow workpiece, and incomplete shot peening on the inner wall of the elbow, so as to improve the fixation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

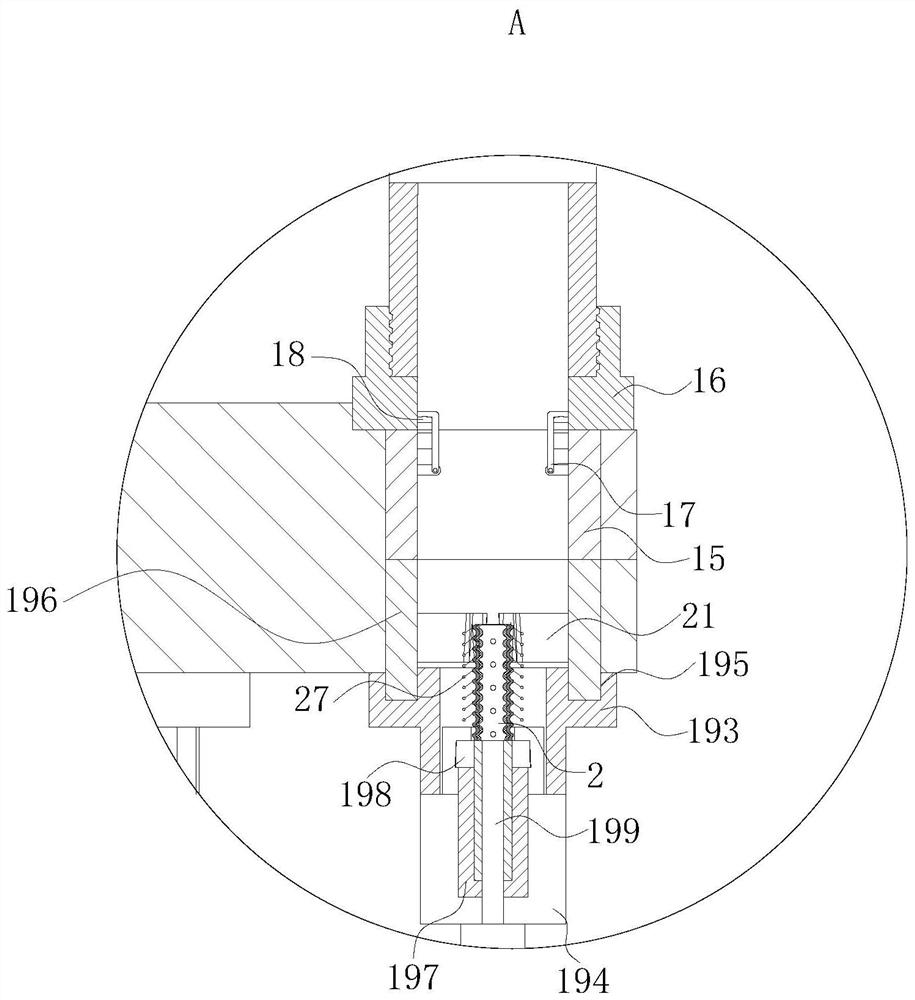

[0033] As an embodiment of the present invention, the side of the first spray head 22 close to the machine body 1 is provided with a spray cover 23 in the inner wall of the manipulator, and the spray cover 23 is designed to rotate; the inner wall of the spray cover 23 is provided with an arc shaped groove 24, and the arc shaped groove 24 communicates with the storage box through a tube; the inner wall of the arc shaped groove 24 is provided with evenly arranged spouts;

[0034] When working, because the first spray head 22 is connected with the spray cover 23 outside the rotation, it can prevent the shot from flying around during the spraying process of the first spray head 22, thereby increasing the collection of the shot shot. Since the inner wall of the spray cover 23 has an arc Groove 24, the gas can blow the shot into the arc groove 24, when the shot flows into the arc groove 24, it can be sprayed out through the evenly arranged nozzles, and the outer surface of the elbow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com