Frame supporting structure of omnidirectional carrying AGV and pallet truck

A support structure and knapsack technology, applied in the field of AGV pallet trucks, can solve problems such as easy slippage, and achieve the effect of increasing ground adhesion, uniform force and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

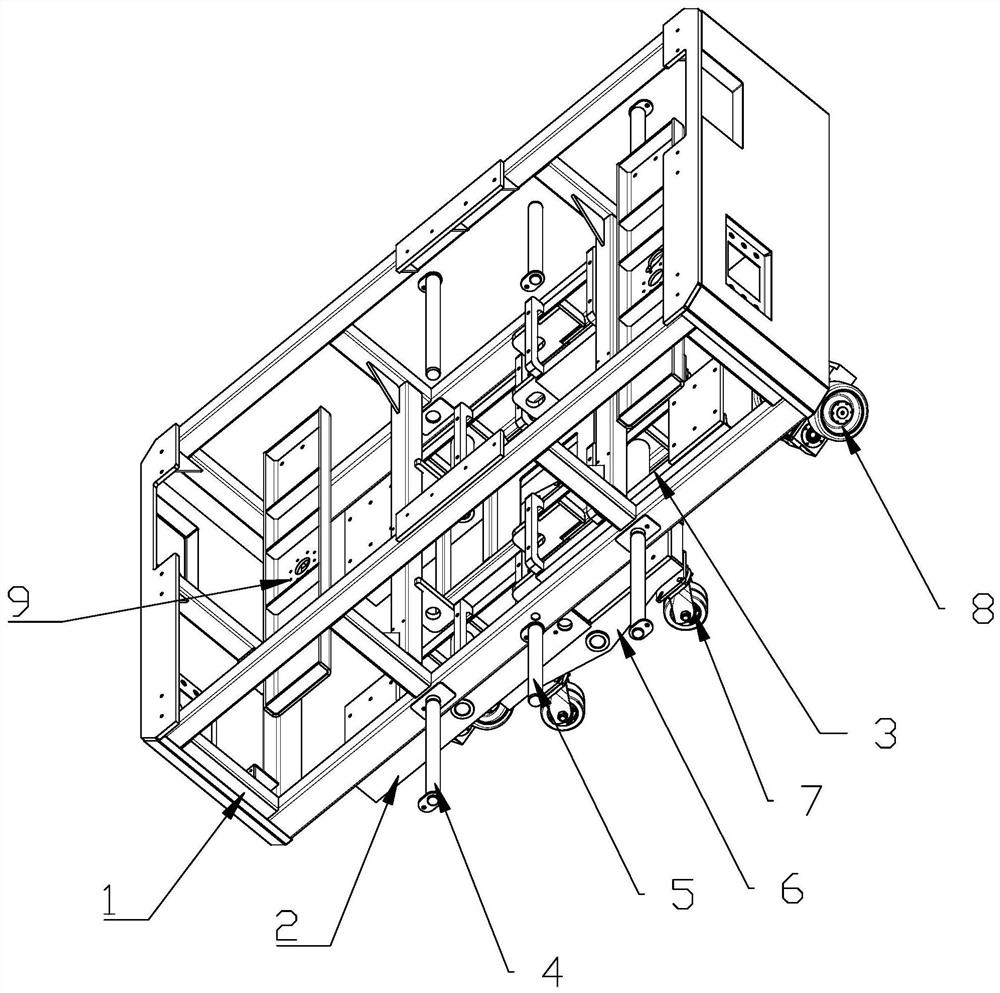

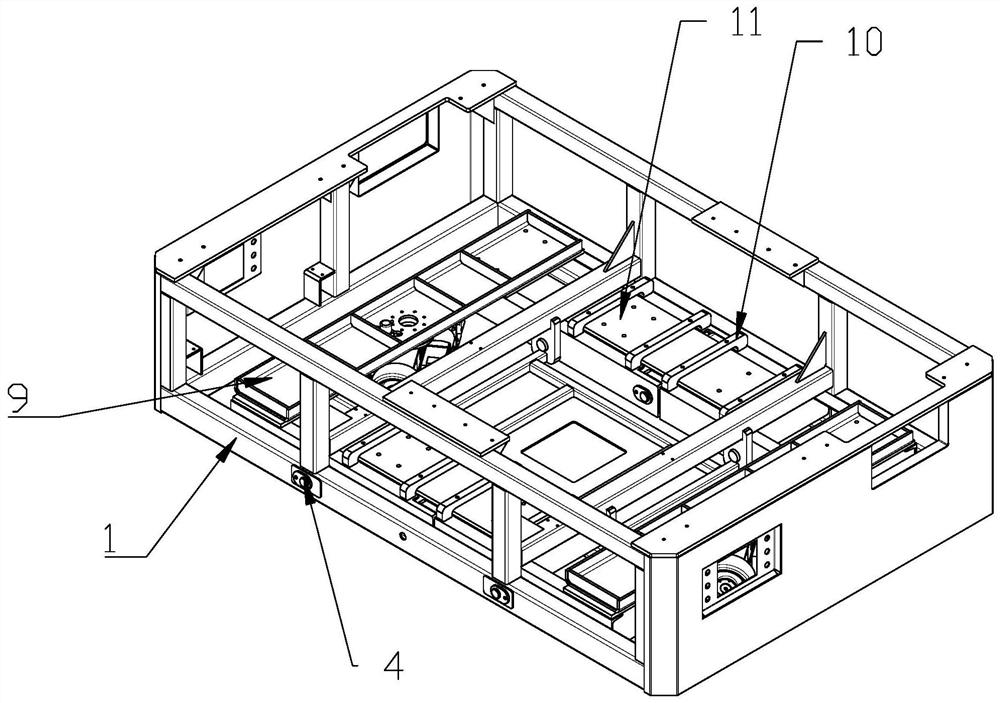

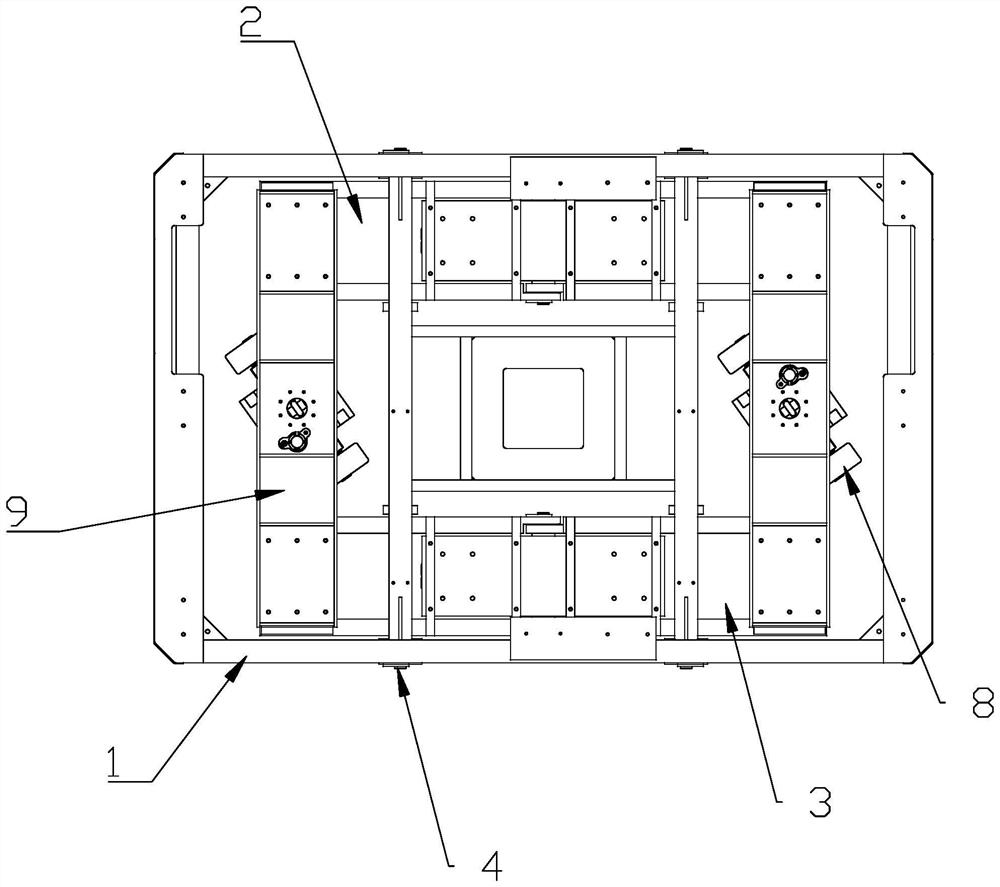

[0053] see Figure 1-11 , this embodiment provides a frame support structure of an omnidirectional knapsack AGV, the frame support structure is used to support goods or materials, and can be automatically transported to a designated location. In this embodiment, the support structure of the vehicle frame is generally square, and a space for accommodating or placing goods / materials is provided. Wherein, the vehicle frame support structure includes a vehicle frame 1, a floating structure 2, a floating structure 3, a rotating shaft 4, a rotating shaft 2 5, a seesaw 6, a universal wheel 7, a differential drive wheel 8, a connecting piece 9 and a limiter. bit board11.

[0054] read on Figure 1-5 , the vehicle frame 1 is a receiving device for goods or materials, and its specific shape and size are generally determined according to actual needs. The vehicle frame 1 is a frame structure, which is in the shape of a cuboid, and each corner is rounded to reduce damage caused by coll...

Embodiment 2

[0070] This embodiment provides a frame support structure of an omnidirectional backpack AGV, and a controller is added to the frame support structure on the basis of Embodiment 1. The controller is used to control the differential drive wheels 8, and obtains a driving path according to a driving command input from the outside. The travel path includes the relationship between the amount of forward rotation of the differential drive wheel 8 and time, the relationship between the deflection angle and time, and the relationship between the amount of reverse rotation and time. Specifically, in a certain period of time one, the controller will keep the deflection angle of the differential drive wheel 8 at a preset angle according to the instruction, and at the same time make the differential drive wheel 8 move forward at a constant speed, so that the support can be realized. The corner process of the structure. In a certain period of time 2, the controller will make the deflectio...

Embodiment 3

[0072]This embodiment provides a frame support structure of an omnidirectional knapsack AGV, and a remote control system is added to the frame support structure on the basis of Embodiment 2. The remote control system mainly includes a receiver part and a transmitter part, the receiver part is directly installed on the vehicle frame 1 or the differential drive wheel 8, and the transmitter part is a mobile terminal used by the user. The transmitter part can transmit the instruction that the user needs to send to the receiver part through the electric signal, and the receiver part analyzes the electric signal and transmits it to the controller, and the controller controls the differential drive wheel 8 according to the instruction, so that the vehicle Rack 1 moves according to the path corresponding to the instruction. In this way, the user can remotely control the supporting structure of the vehicle frame without manual operation, which is convenient to use and can improve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com