Deep purification pond chain treatment process for dredging tail water

A deep purification and treatment process technology, applied in the field of water treatment, can solve the problems of large consumption of adsorption materials, high cost, and limited follow-up use of tail water effluent, and achieve small maintenance workload, good adaptability, and reuse purposes wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

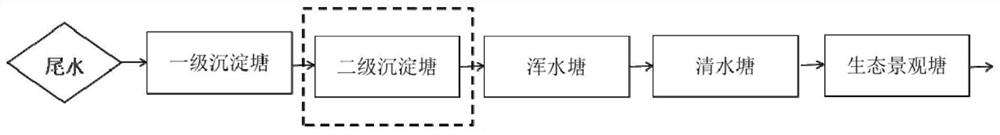

[0041] The pond chain is connected to the dredging and dewatering pond. The pond chain includes the first-level sedimentation pond, the second-level sedimentation pond, the muddy water pond, the clear water pond and the ecological landscape pond. way to connect. Tail water treatment volume is 2000m 3 / h.

[0042] (1) The water depth of the primary sedimentation pond is 3m, the hydraulic retention time is 0.2d, and the area of a primary sedimentation pond is 3200m 2, set up two sets of first-level sedimentation ponds, and use them alternately.

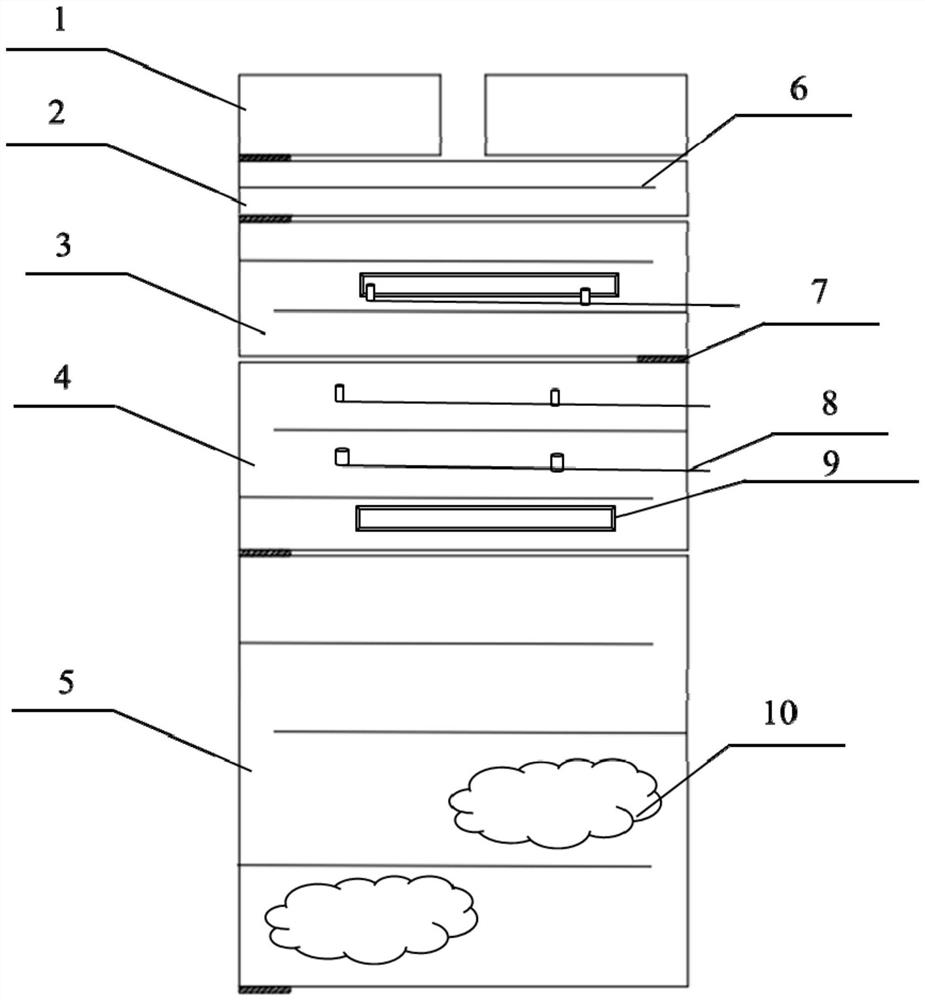

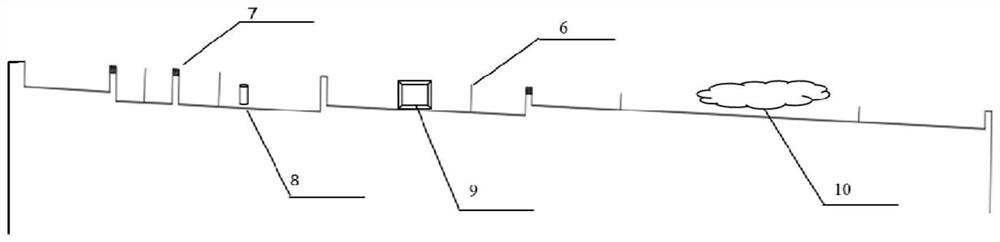

[0043] (2) The water depth of the secondary sedimentation pond is 4m, the hydraulic retention time is 0.5d, and the pond area is 6000m 2 , There is a diversion dam in the pond to guide the flow of water.

[0044] (3) The water depth of the muddy pond is 4m, the hydraulic retention time is 1d, and the pond area is 12000m 2 , Diversion dams are set in the pond, aeration devices and bionic aquatic plants are arranged.

[0045] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com