Floor block and manufacturing method thereof

A production method and technology of floor boards, which are applied to floors, buildings, building structures, etc., can solve the problems of honeycomb substrate disintegration, easy damage, and inability to achieve impact resistance, and achieve fast curing speed, saving usage, and excellent resistance. The effect of compressive and flexural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

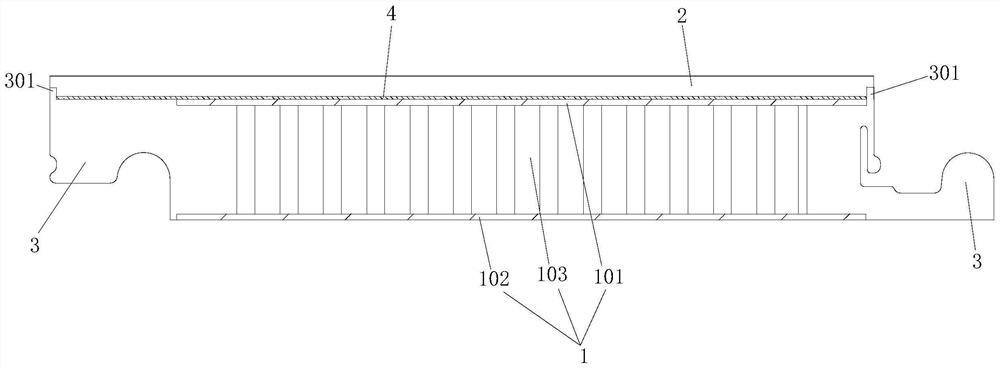

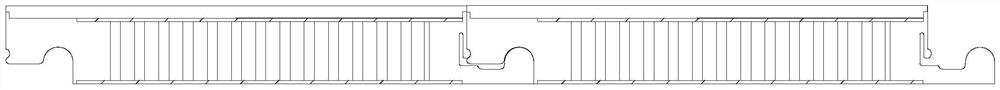

[0058] Figure 1 to Figure 5 A preferred embodiment of the floorboard of the present application is shown. The same structure as the floorboard mentioned in the background art is that the floorboard also includes a honeycomb substrate 1 and a panel 2 that is attached to and fixed on the upper surface of the honeycomb substrate. .

[0059] The difference from traditional honeycomb panels is:

[0060] In this embodiment, the honeycomb substrate 1 includes: a honeycomb core layer 103, an upper plate body 101 bonded and fixed on the upper surface of the honeycomb core layer by a thermosetting adhesive (rather than a hot-melt adhesive), and a thermosetting adhesive ( The lower plate body 102 is bonded and fixed on the lower surface of the honeycomb core layer by using non-hot-melt adhesives. The panel 2 is bonded and fixed on the upper surface of the upper plate body 101 by a thermosetting adhesive.

[0061] When crafting this floor block:

[0062] First, the upper surface of t...

Embodiment 2

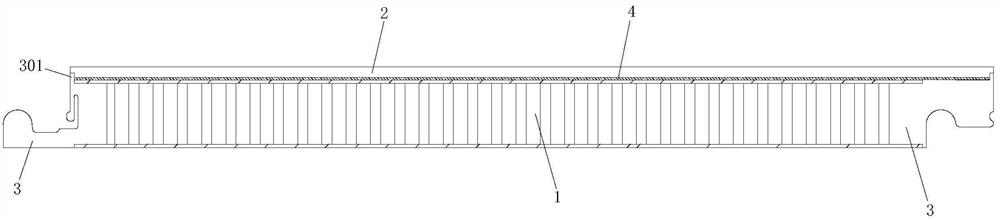

[0079] Figure 6 and Figure 7 Another preferred embodiment of the floorboard of the present application is shown, the structure of the floorboard is basically the same as that of Embodiment 1, the main difference is only in:

[0080] The panel 2 is bonded and fixed to the upper surface of the upper plate body 101 by means of a hot-melt adhesive (instead of the thermosetting adhesive in Embodiment 1).

[0081] Further, the panel 2 and the upper panel body 101 of the honeycomb substrate 1 are bonded and fixed by the hot melt adhesive film 6 sandwiched between them.

[0082] refer to Figure 6 As shown, when crafting this floorboard:

[0083] First, the upper surface of the lower plate body 102 and the lower surface of the upper plate body 101 are coated with a liquid thermosetting adhesive, and the honeycomb core layer 103 is arranged between the lower plate body 102 and the upper plate body 101. 102 and the upper plate 101 apply a clamping force close to each other to sque...

Embodiment 3

[0089] refer to Figure 8 to Figure 12 As shown, the structure of the floorboard of this embodiment is basically the same as that of Embodiment 1. The main difference is that the honeycomb core layer of the honeycomb substrate in this embodiment adopts another structure, thereby improving the honeycomb core layer 103 and the upper plate body 101 and The bonding area and bonding strength of the lower plate body 102 reduce the possibility of the upper and lower plate bodies detaching from the honeycomb core layer as follows:

[0090]The honeycomb core layer 103 is composed of a very thin metal sheet 1031 and punching the metal sheet to integrally form a plurality of downwardly protruding punching protrusions 1032 on the metal sheet. The upper surface 1031a of the metal sheet 1031 is attached to and bonded to (the lower surface of) the upper plate body 101 , and the lower surface 1032a of the punching protrusion 1032 is attached to and bonded to (the upper surface of) the lower p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com