Ultrahigh-molecular weight polyethylene modified nylon 66 and preparation method thereof

An ultra-high molecular weight, polyethylene modification technology, applied in the field of modified nylon 66, can solve the problem of poor wear resistance of nylon 66, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

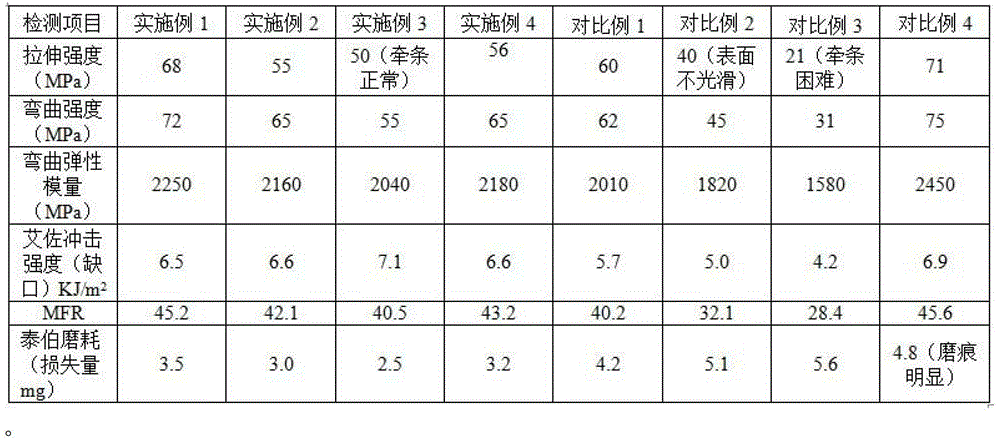

Examples

Embodiment 1

[0021] Weighing mass fraction is 10% heterogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, 88% nylon 66, 0.3% composite antioxidant, 1.7% lubricant, the relative viscosity of said nylon 66 is 2.5, non Homogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, with an average molecular weight of 1 million and a density of 0.936-0.946g / cm 3 , Particle size: 80-100 mesh, heterogeneous surface grafted with maleic anhydride ultra-high molecular weight polyethylene powder particles The manufacturing method is to use acetic anhydride as the medium, maleic anhydride as the grafting agent, benzoyl peroxide ( BPO) as the initiator, carry out heterogeneous grafting, the reaction temperature is 80-120 ° C, according to the method recorded on pages 26-30 of the third issue of "Modern Plastics Processing and Application" in 1993, the grafting rate of maleic anhydride is obtained 0.5% ultra-high molecular weight polyethylene grafted with maleic ...

Embodiment 2

[0025] Weighing mass fraction is 20% heterogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, 79.4% nylon 66, 0.1% composite antioxidant, 0.5% lubricant, and the relative viscosity of said nylon 66 is 2.6, not Homogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, with an average molecular weight of 3 million and a density of 0.936-0.946g / cm 3 , Particle size: 80-100 mesh, ultra-high molecular weight polyethylene powder particles grafted with maleic anhydride on the heterogeneous surface Cumene is used as an initiator to carry out heterogeneous grafting. The reaction temperature is 80-120 ° C. According to the method recorded on pages 26-30 of the third phase of "Modern Plastics Processing and Application" in 1993, the grafting ratio of maleic anhydride is obtained. It is the ultra-high molecular weight polyethylene grafted with maleic anhydride on the heterogeneous surface of 0.8%; the composite antioxidant is antioxidant 1010 (...

Embodiment 3

[0028] Taking by weighing mass fraction is 30% heterogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, 68% nylon 66, 0.3% composite antioxidant, 1.7% lubricant, and the relative viscosity of described nylon 66 is 2.8, very Homogeneous maleic anhydride grafted ultra-high molecular weight polyethylene, with an average molecular weight of 6 million and a density of 0.936-0.946g / cm 3, Particle size: 80-100 mesh, UHMWPE powder particles grafted with maleic anhydride on the heterogeneous surface The manufacturing method is to use propionic anhydride as the medium, maleic anhydride as the grafting agent, 2,5 dimethyl 2,5 di-tert-butylperoxyhexyne is used as an initiator to carry out heterogeneous grafting, and the reaction temperature is 80-120 ° C. According to the method recorded on pages 26-30 of the third issue of "Modern Plastics Processing and Application" in 1993, Obtain the ultra-high molecular weight polyethylene of heterogeneous surface grafting mal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com