Anti-corrosion reinforcing method and device for reinforced concrete structure

A reinforced concrete and reinforcement device technology, which is applied in the direction of clay preparation device, supply device, unloading device, etc., can solve the problems of reducing the structural strength of reinforced concrete, not increasing the anti-corrosion performance, and not being able to mix and use at the same time, so as to improve the strength, Quick and efficient mixing, improving the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

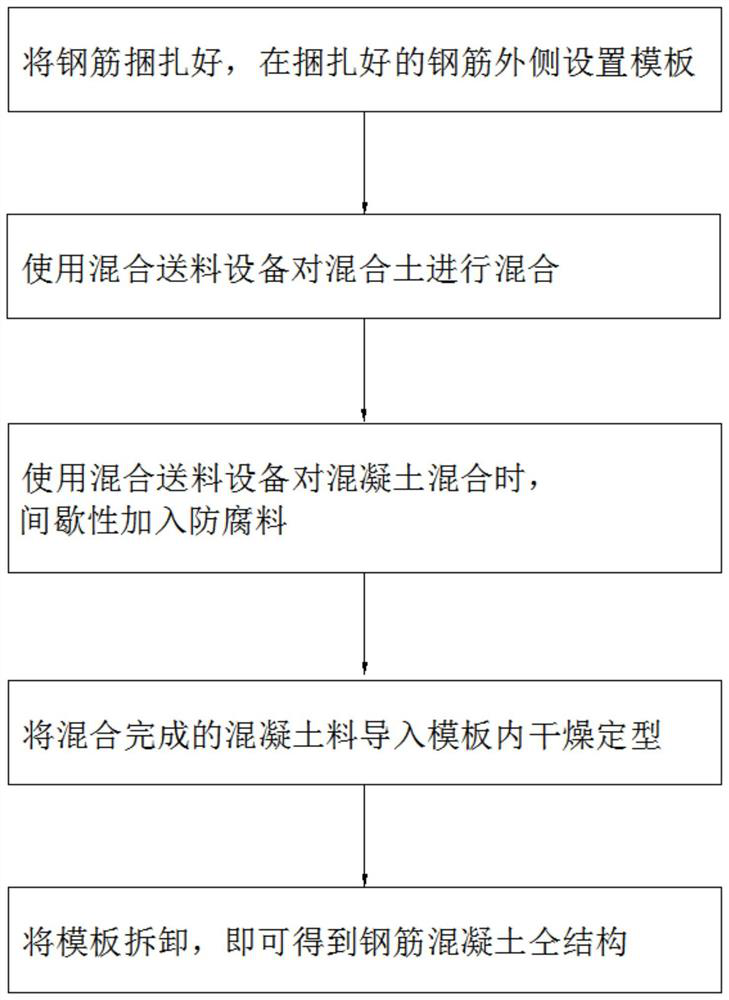

[0034] refer to figure 1 , a kind of reinforced concrete same structure anticorrosion strengthening method, comprises the following steps:

[0035] S1: Bundle the reinforcement, and set a formwork outside the bundled reinforcement;

[0036] S2: Mix the mixed soil with mixing feeding equipment;

[0037] S3: When using mixing and feeding equipment to mix concrete, add anti-corrosion materials intermittently;

[0038] S4: Import the mixed concrete material into the formwork to dry and shape;

[0039] S5: The formwork is disassembled to obtain a reinforced concrete structure.

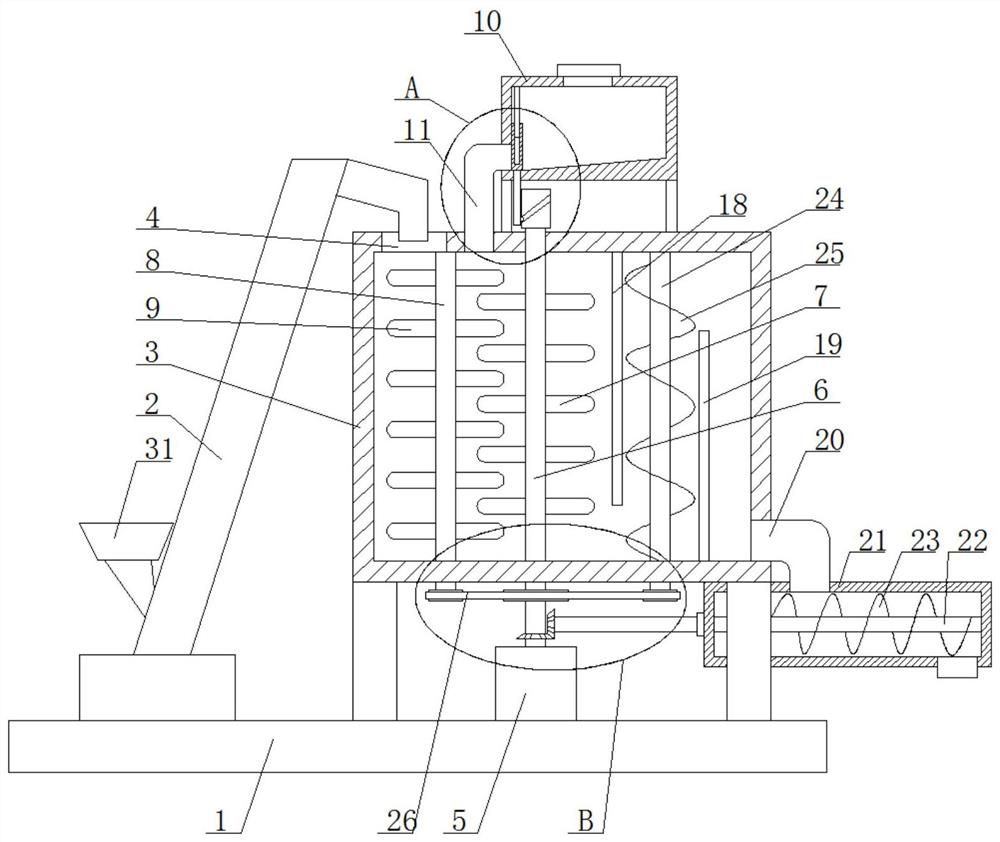

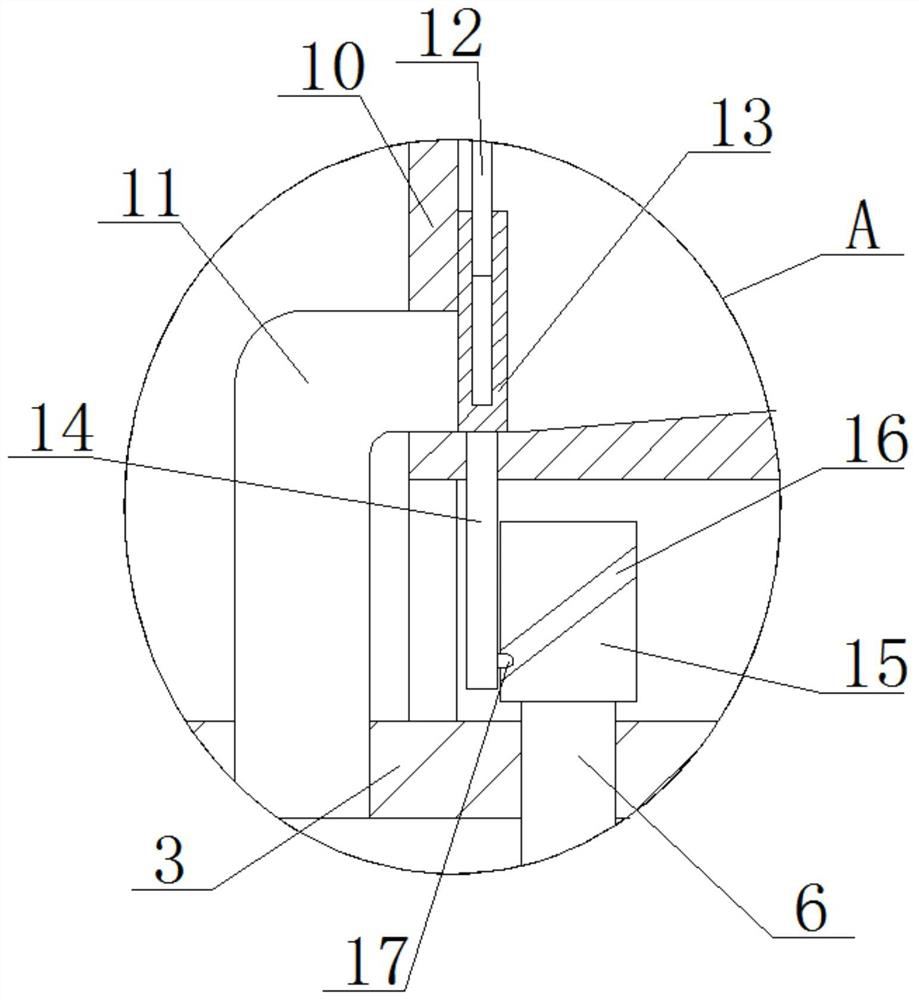

[0040] refer to Figure 2-5 , a reinforced concrete anticorrosion reinforcement device with the same structure, including a feeding device, a mixing feeding device and a base 1, the feeding device includes a screw feeder 2, the mixing feeding device includes a mixing tank 3 and a feeding structure, the screw feeding device 2 and The mixing and feeding equipment is all arranged on the top of the base 1,...

Embodiment 2

[0051] refer to figure 1 , a kind of reinforced concrete same structure anticorrosion strengthening method, comprises the following steps:

[0052] S1: Bundle the reinforcement, and set a formwork outside the bundled reinforcement;

[0053] S2: Mix the mixed soil with mixing feeding equipment;

[0054] S3: When using mixing and feeding equipment to mix concrete, add anti-corrosion materials intermittently;

[0055] S4: Import the mixed concrete material into the formwork to dry and shape;

[0056] S5: The formwork is disassembled to obtain a reinforced concrete structure.

[0057] refer to Figure 2-5 , a reinforced concrete anticorrosion reinforcement device with the same structure, including a feeding device, a mixing feeding device and a base 1, the feeding device includes a screw feeder 2, the mixing feeding device includes a mixing tank 3 and a feeding structure, the screw feeding device 2 and The mixing and feeding equipment is all arranged on the top of the base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com