System for synergistically controlling corner gas by blocking gas wall and magnetized active agent and method

A technology of active agent and surfactant, which is applied in the direction of gas discharge, earthwork drilling, safety devices, etc., can solve the problems of small flow rate, large solution consumption, and low extraction concentration, so as to reduce gas release and gas surge The effect of output and prolonged release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

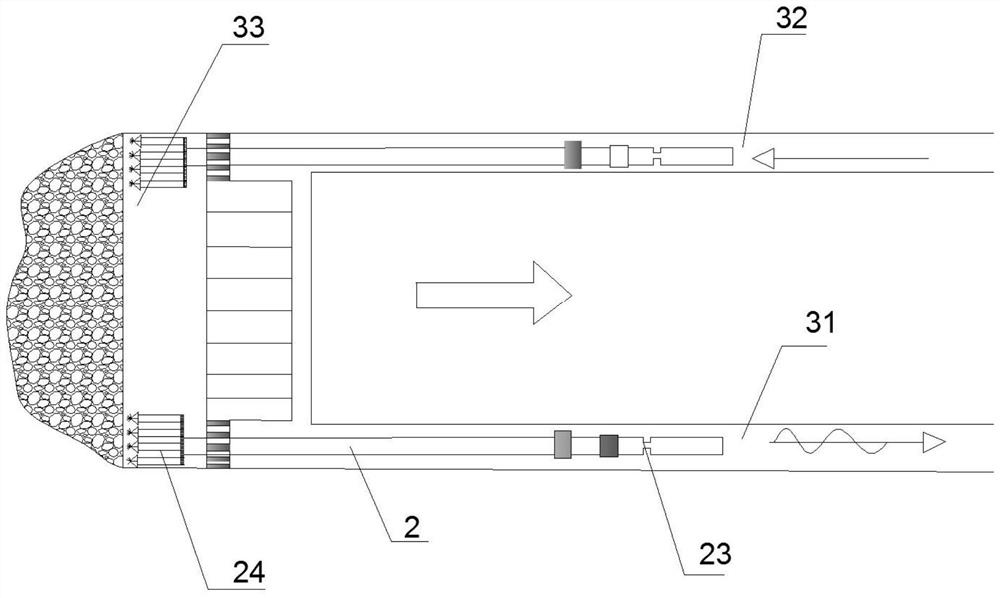

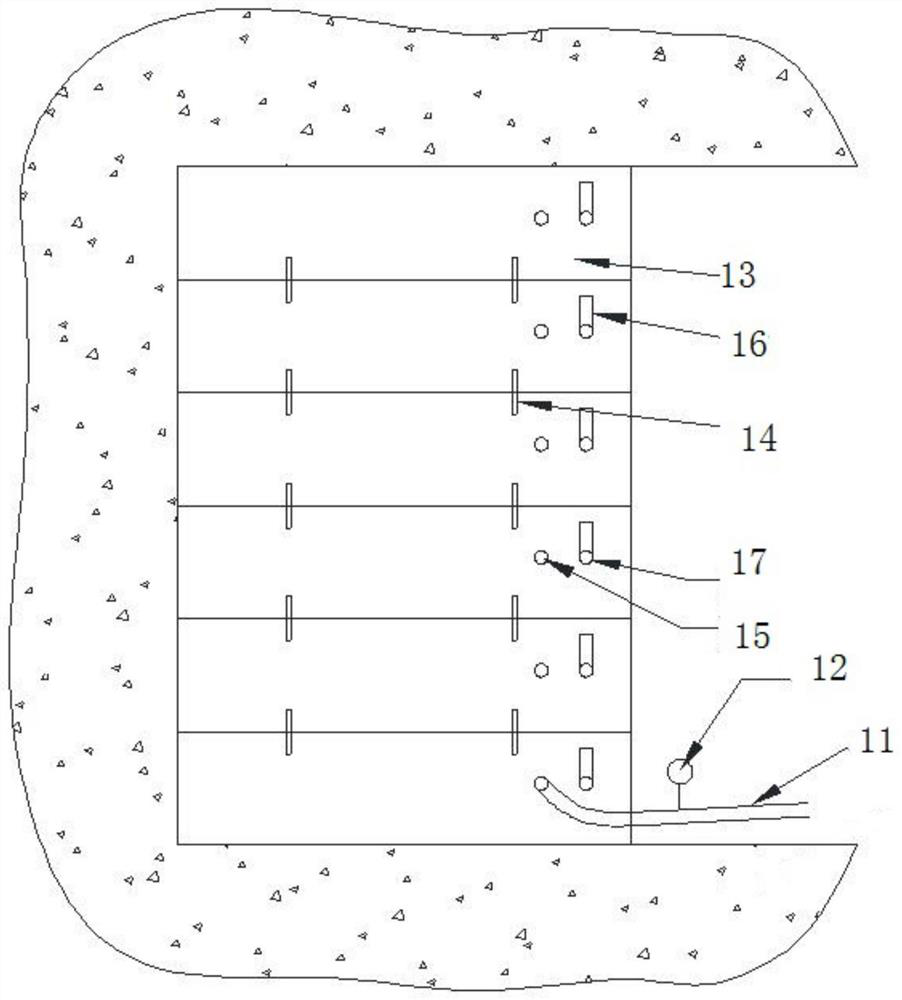

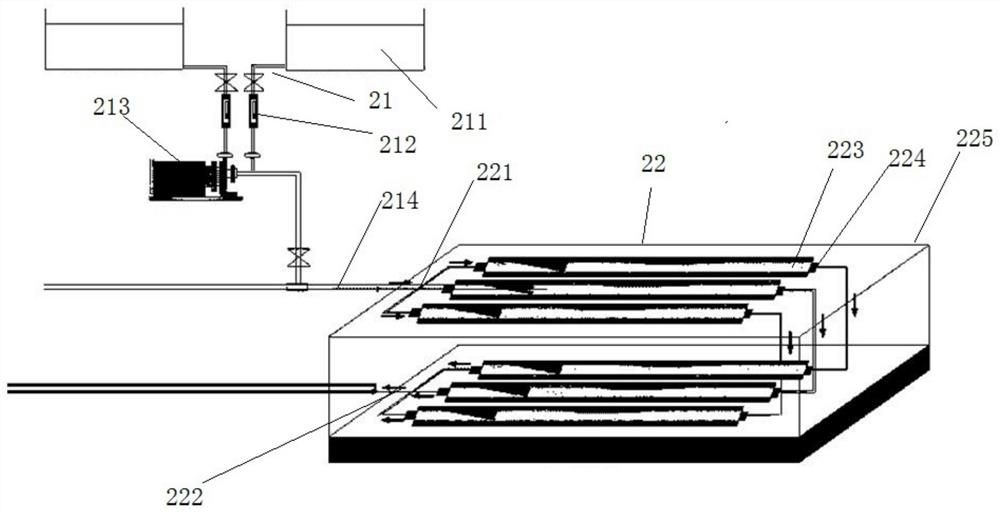

[0033] Such as Figure 1~3 As shown, a closed gas wall and magnetizing active agent cooperatively control the corner gas system, including the gas wall assembly 1 and the spray assembly 2, the air wall assembly 1 is set on the mining channel, and the spray assembly 2 is set At the position close to the corner surface, the air wall assembly 1 is used to block the passage where the working surface is located, so that the upper corner area can be ventilated smoothly and reduce the accumulation of gas; the spray assembly 2 is used to spray the magnetic surfactant to In the corner area, the gas is desorbed and suppressed to reduce the generation of gas.

[0034] The air wall assembly 1 includes a gas pipeline 11, a pressure gauge 12, an air bag 13, a buckle 14, an inflation valve, a safety valve 16 and a pressure relief hole 17; the inflation valve, the safety valve 16 and the pressure relief hole 17 are all set On the airbag 13, the gas is filled into the airbag 13 through the in...

Embodiment 2

[0051] The present invention also provides a method for synergistically controlling corner gas by sealing an air wall and a magnetizing active agent, which specifically includes the following steps:

[0052] Step 1: Install the air bag 13 assembly in the intersection area between the goaf and the working face, and pressurize it, reduce the air volume entering the goaf, and reduce the accumulation of gas in the goaf and the working face;

[0053] Step 2: Spray a magnetized surfactant on the corner working face to desorb and suppress the accumulation of gas and reduce the formation of gas;

[0054] Step 3: Release the pressure and move the air bag 13 assembly. When the air bag 13 assembly is moved to a suitable position, start the spraying assembly to suppress the gas desorption, and the magnetizing active agent is sprayed on the corner through the collaborative governance pipeline system to achieve the corner gas quickly. Governance purposes; then repeat steps one and two.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com