Vacuum waste heat steam boiler

A waste heat steam and boiler technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of difficult control, large energy consumption, excessive power consumption, etc., to reduce boiler volume and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment (accompanying drawing).

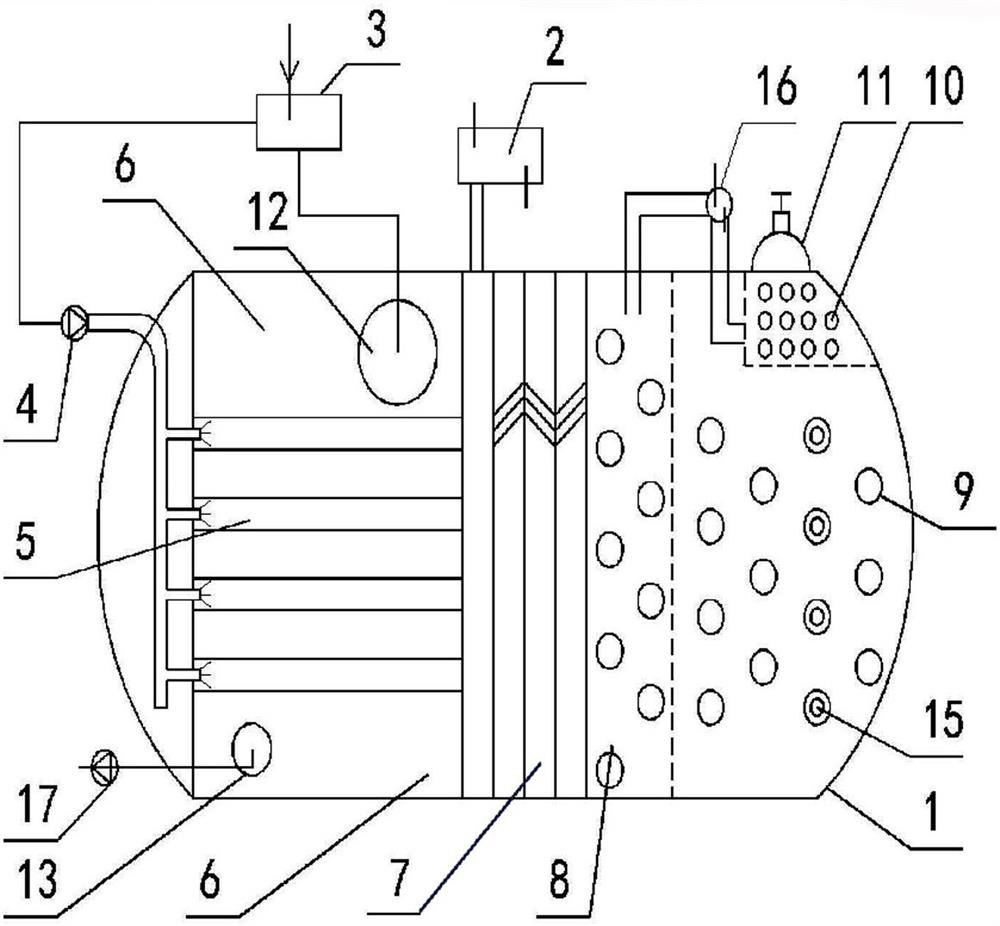

[0036] Such as figure 1 As shown, the vacuum waste heat steam boiler of the present invention includes a boiler casing 1 connected with a vacuum pump 2 capable of withstanding a vacuum degree of <400 Pa, a warm water evaporation chamber 5, a water baffle 7, and a second evaporation chamber sequentially arranged in the boiler casing 8. The high-temperature heating chamber 9 and the steam storage chamber 10 located above the side of the high-temperature heating chamber 9; in the middle of the warm water evaporation chamber 5, an evaporator composed of several evaporation tubes arranged in a longitudinal direction is arranged, and a communication channel is arranged above the evaporator. The waste heat and warm water inlet 12 of the boiler water distribution device 3 is provided with a waste heat and warm water outlet 13 below the evaporator; one end of several ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com