Humidity adjusting device and method using chilled water for reheating

A technology for chilled water and chilled water systems, which is used in household heating, heating methods, household heating, etc., can solve the problems of complex systems and high overall energy consumption, simplify energy pipelines or systems, improve energy-saving efficiency, reduce effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

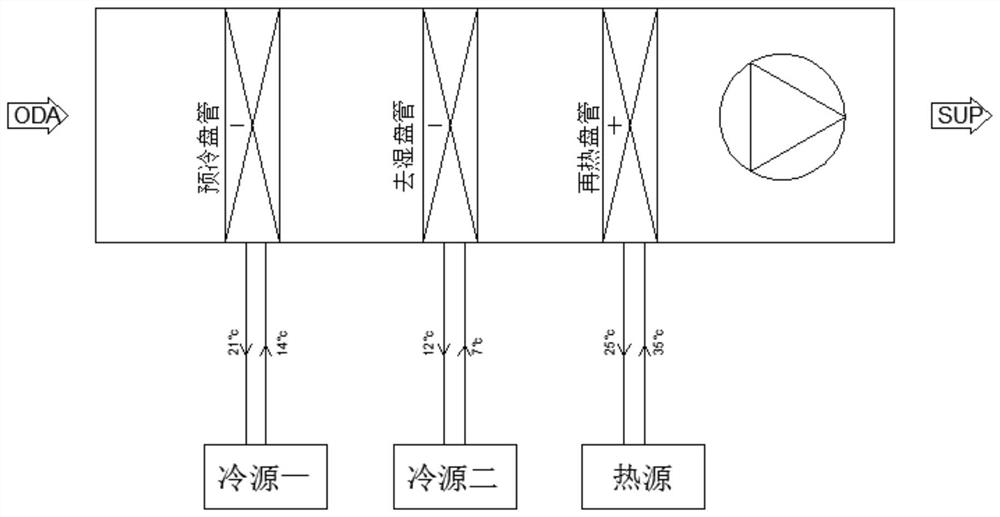

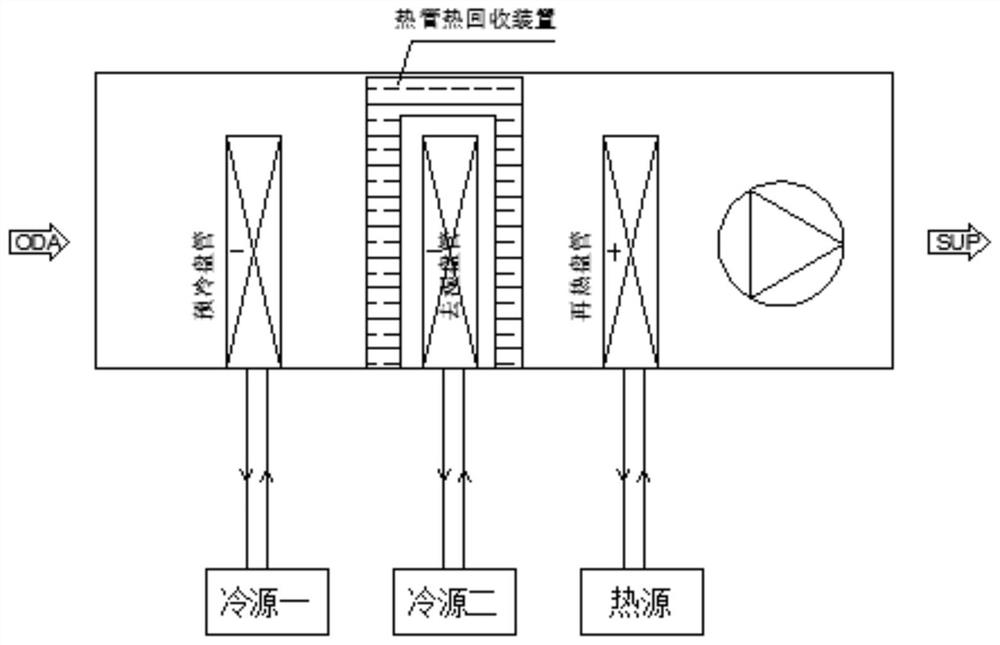

Problems solved by technology

Method used

Image

Examples

Embodiment 1

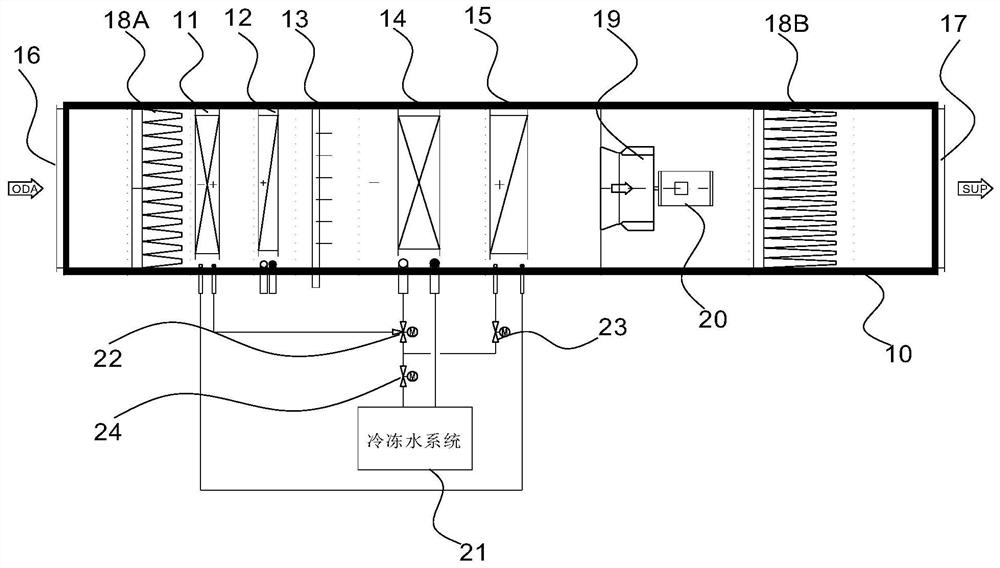

[0026] Such as image 3 and Figure 4 As shown, this embodiment provides a humidity control device using chilled water for reheating, including a first heat exchanger 11, a second heat exchanger 12, a humidifier 13, a third heat exchanger 14 and a fourth heat exchanger The air flows into the first heat exchanger 11, the second heat exchanger 12, the humidifier 13, the third heat exchanger 14 and the fourth heat exchanger 15 sequentially through the air inlet 16, and is discharged through the air outlet 17. The water inlet channel of the third heat exchanger 14 is connected to the chilled water system 21, and the water outlet channel of the third heat exchanger 14 is connected to the water inlet channel of the first heat exchanger 11 through the first valve 22, so The water outlet channel of the first heat exchanger 11 is connected to the water inlet channel of the fourth heat exchanger 15 , and the water outlet channel of the fourth heat exchanger 15 is connected to the chill...

Embodiment 2

[0040] Such as image 3 As shown, this embodiment provides a humidity control method for reheating with chilled water, using the humidity control device for reheating with chilled water described in Implementation 1 to adjust the temperature and humidity of the air, including step S1: The low-temperature chilled water in the water system 10 performs heat exchange, so that the low-temperature chilled water becomes medium-temperature chilled water, and the medium-temperature chilled water is used to perform the first heat exchange on the air to cool down the air, and the flow rate of the medium-temperature chilled water is controlled to make the medium-temperature After the chilled water has undergone heat exchange, high-temperature chilled water is discharged; step S2: perform a second heat exchange on the cooled air to heat up the air, and perform humidification treatment on the heated air; step S3: utilize the low temperature in the chilled water system 10 The chilled water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com