Solid-state fused salt energy storage tank

An energy storage tank and molten salt technology, which is applied in the field of energy storage, can solve the problems of the molten salt tank being unable to perform constant temperature operation, inconvenient for heating, and without a circulation device, etc., so as to prevent serious heat loss, reasonable structure design, and prevention of hardening phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

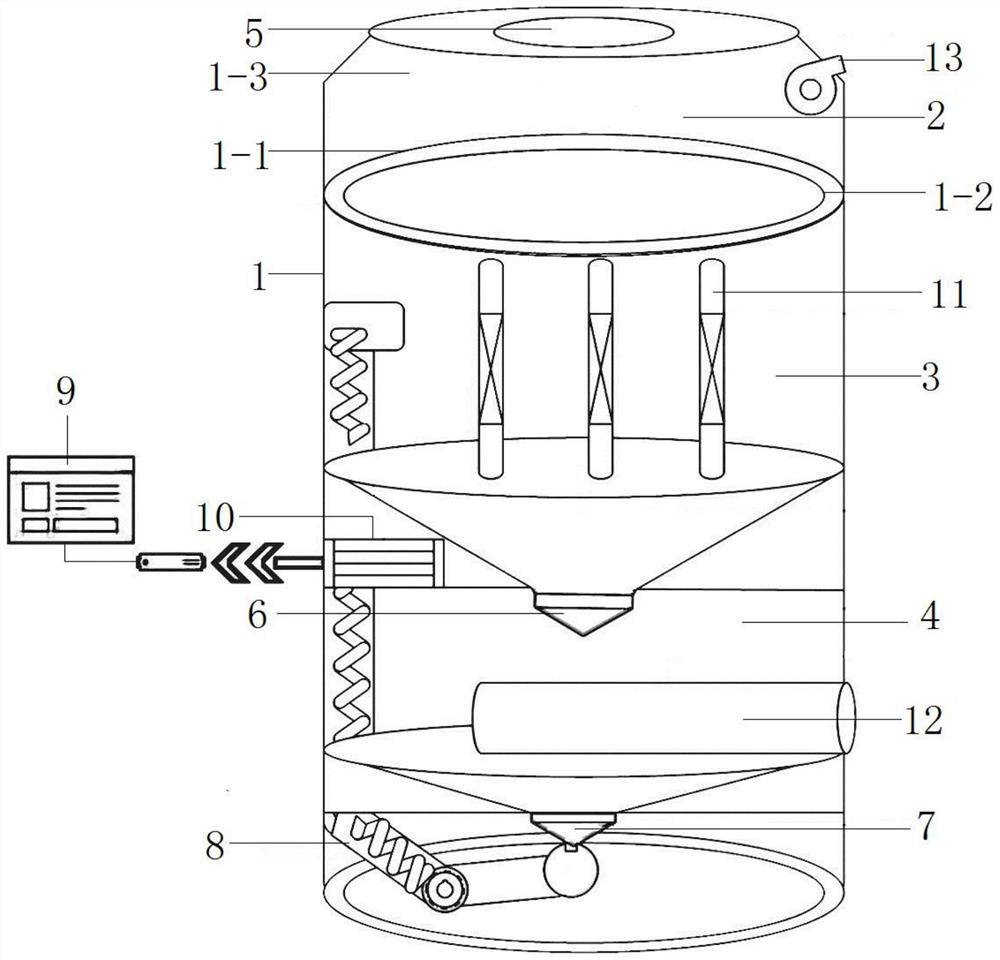

[0029] Such as figure 1 As shown, this embodiment provides a solid-state molten salt energy storage tank, which includes a tank body 1, in which a heat preservation zone 2, a heating zone 3 and a heating zone 4 are sequentially arranged from top to bottom, and the top of the tank body 1 is equipped with There are heat preservation covers 1-3, the top center of the heat preservation cover is provided with a solid molten salt feeding port 5, and the bottoms of the heating zone 3 and the heating zone 4 are respectively provided with a first material gate 6 and a second material gate 7, when the first material When the door 6 is opened, the heating area 3 and the heating area 4 are connected, and the heated solid molten salt enters the heating area from the heating area for heating; a molten salt transmission device is also connected between the heating area 4 and the heating area 3 8. The molten salt conveying device 8 is used to guide the molten salt in the heating area 4 back t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap