A MEMS Piezoelectric Sensor for Measuring the Curvature of Microscale Charge Detonation Wave Front

A piezoelectric sensor and detonation wave technology, applied in the direction of blasting force measurement, can solve the problems of affecting data accuracy, cumbersome data processing, and difficult positioning of the radial port position of optical fiber, achieving high precision, small size, and high output The effect of a large signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

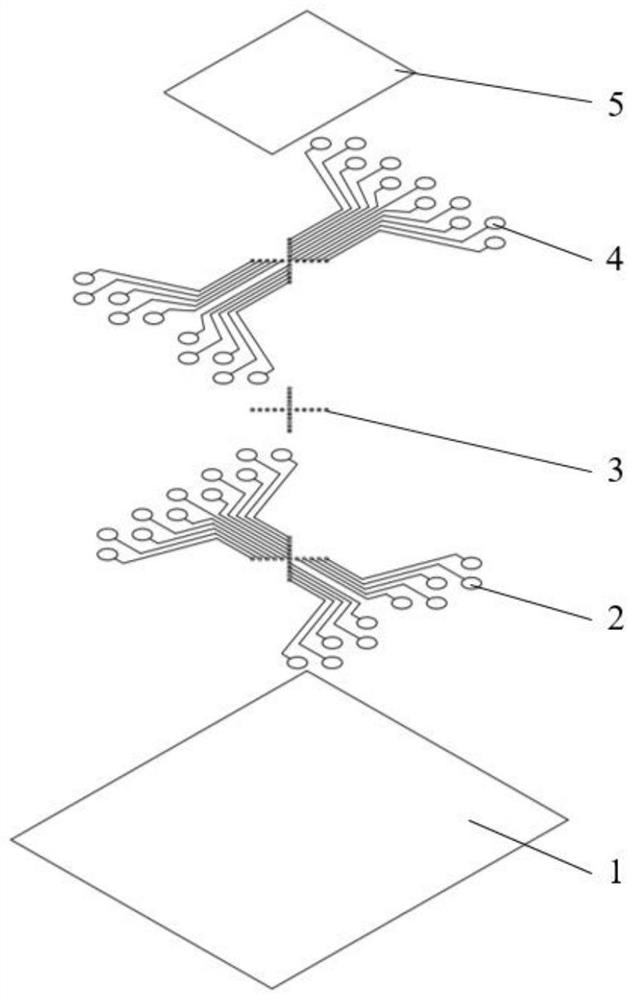

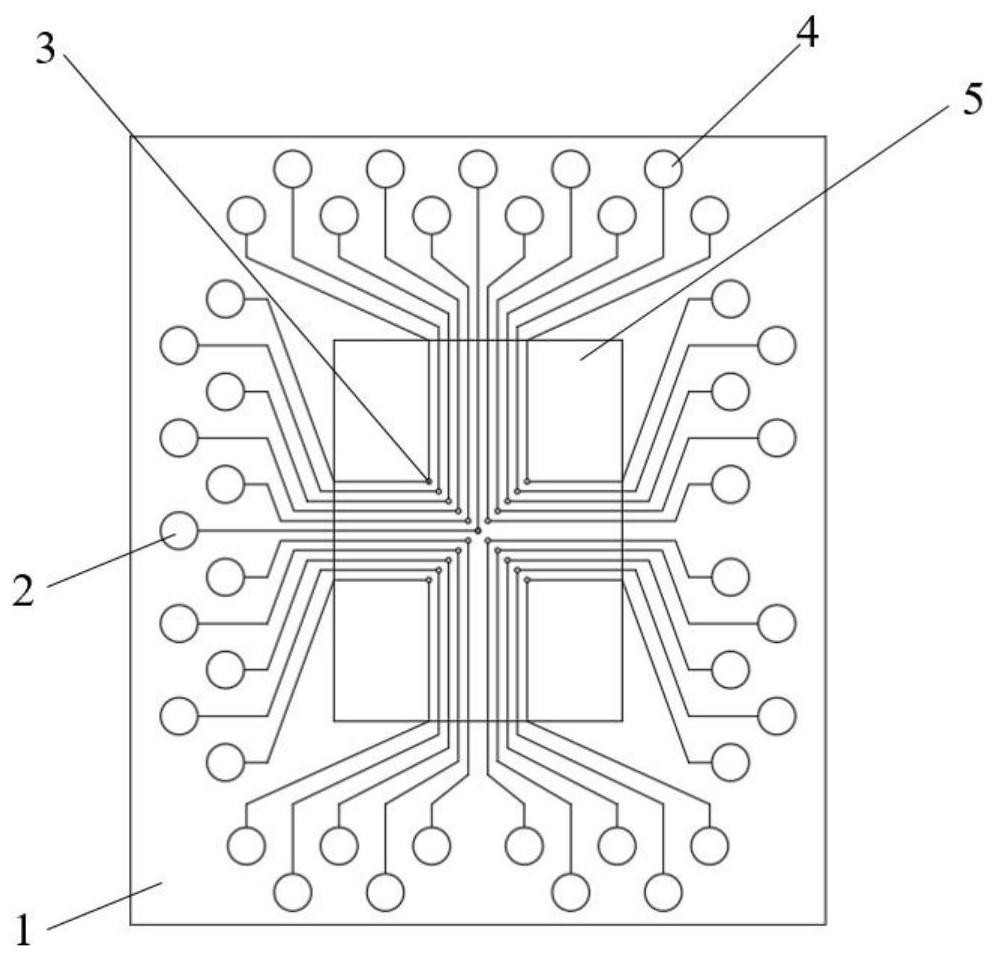

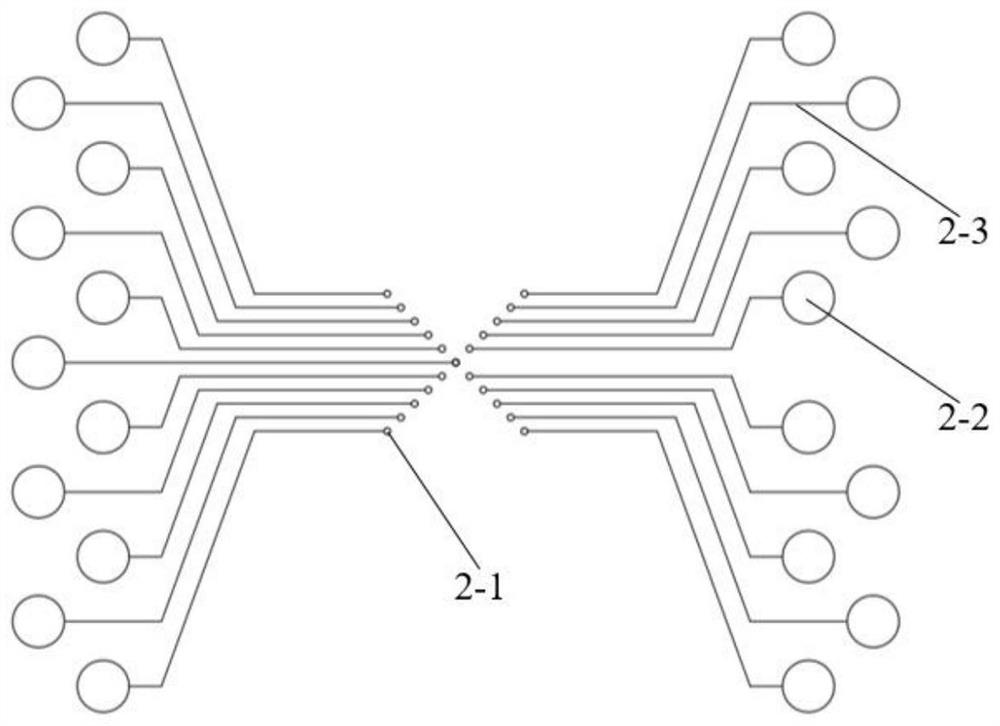

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , a MEMS piezoelectric sensor for measuring the curvature of a microscale charge detonation wave front, including a substrate 1, on which a lower output electrode 2-1 and a lower pad 2-2 are sputtered by a MEMS process, and the lower output electrode 2-1 is sputtered on the lower layer. The electrode 2-1 is connected to the lower layer pad 2-2 through the lower layer wire 2-3 to form the lower layer output layer 2; the lower layer output layer 2 is spin-coated and solidified by a MEMS process to form a polyvinylidene fluoride-trifluoroethylene copolymer ( PVDF-TrFE) thin film layer, and the PVDF-TrFE thin film layer is polarized in a silicon oil bath, and the PVDF-TrFE sensitive element 3-1 is obtained by ion etching (RIE), which constitutes the PVDF-TrFE piezoelectric laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com