Additive manufacturing device and method based on hollow AFM probe localized electro-deposition

A technology of additive manufacturing and electrodeposition, which is applied in the field of additive manufacturing, can solve problems such as inability to realize localized processing, cumbersome operation steps, and strict hardware micro-movement resolution, and meet the requirements of overcoming high-precision moving displacement hardware Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

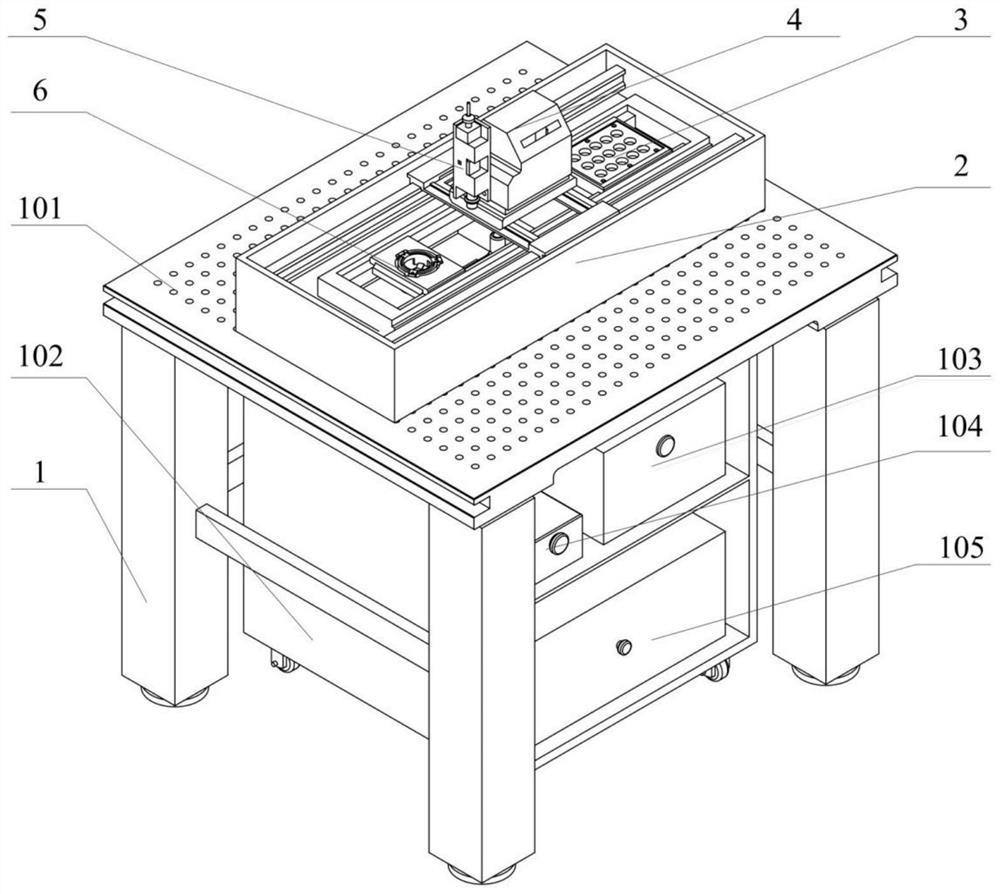

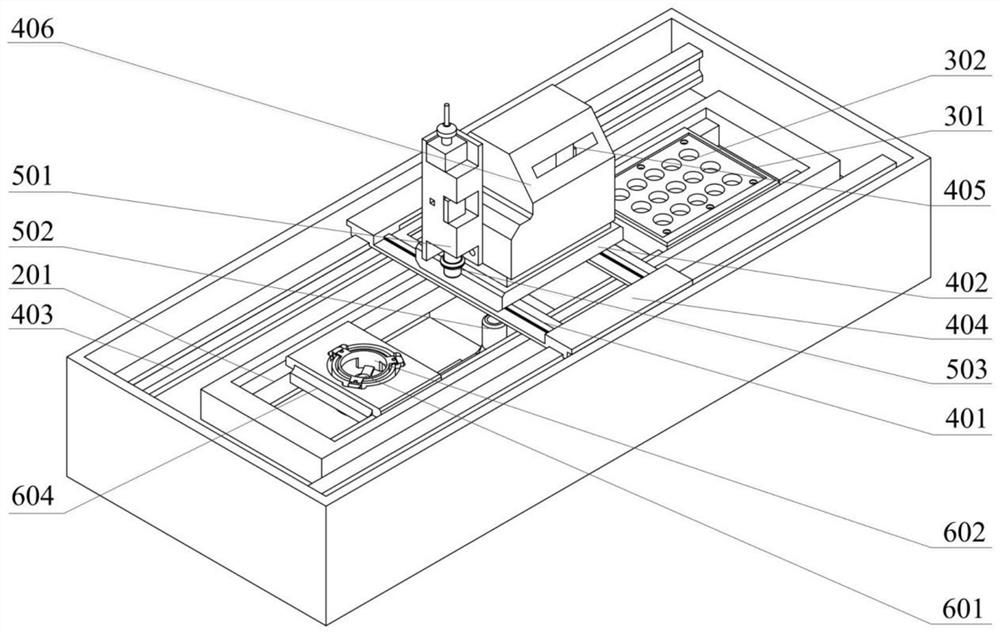

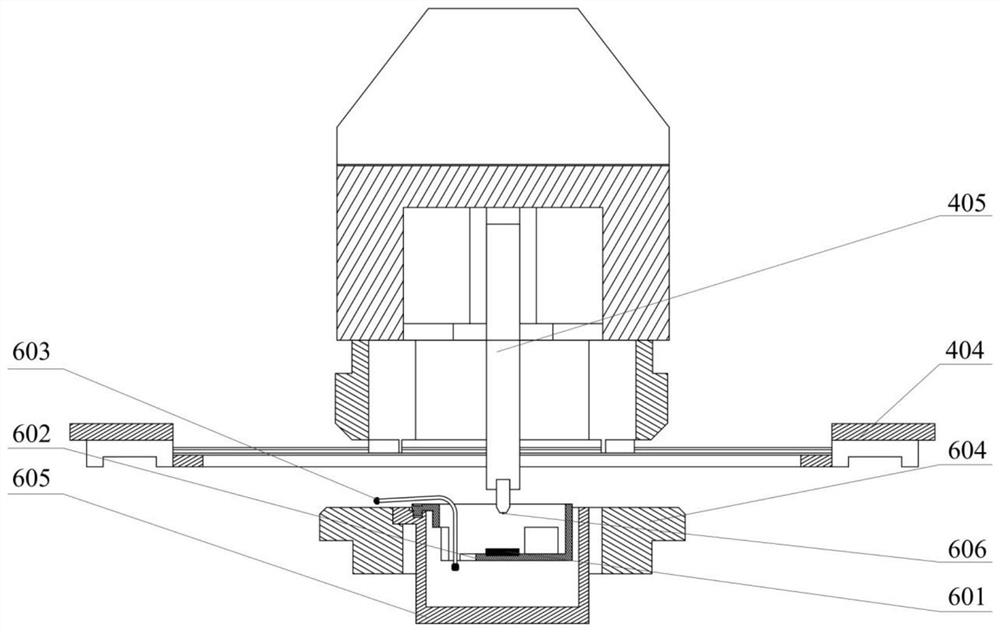

[0041] Additive manufacturing devices based on localized electrodeposition of hollow AFM probes, such as Figure 1 ~ Figure 3 As shown, it includes a vibration isolation system 1, an additive manufacturing device main body 2, a cleaning buffer unit 3, a precision positioning system 4, a monitoring system 5, and an electrode unit 6,

[0042] The vibration isolation system 1 includes a vibration isolation operation platform 101, a control system frame vehicle 102, a hollow AFM cantilever air pressure control system 103, a potentiostat system 104, and a general control system 105; the vibration isolation operation platform 101 is an additive manufacturing device The base of the main body 2 is responsible for the unit of the entire manufacturing system to resist external vibration; the bottom of the control system frame car 102 has four wheels that can move, and the control system frame car 102 is placed in the middle of each component of the control system. Above the control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com