Self-adaptive soft measurement method and system based on vine copula quantile regression

A technique of quantile regression and soft measurement, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of large model error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

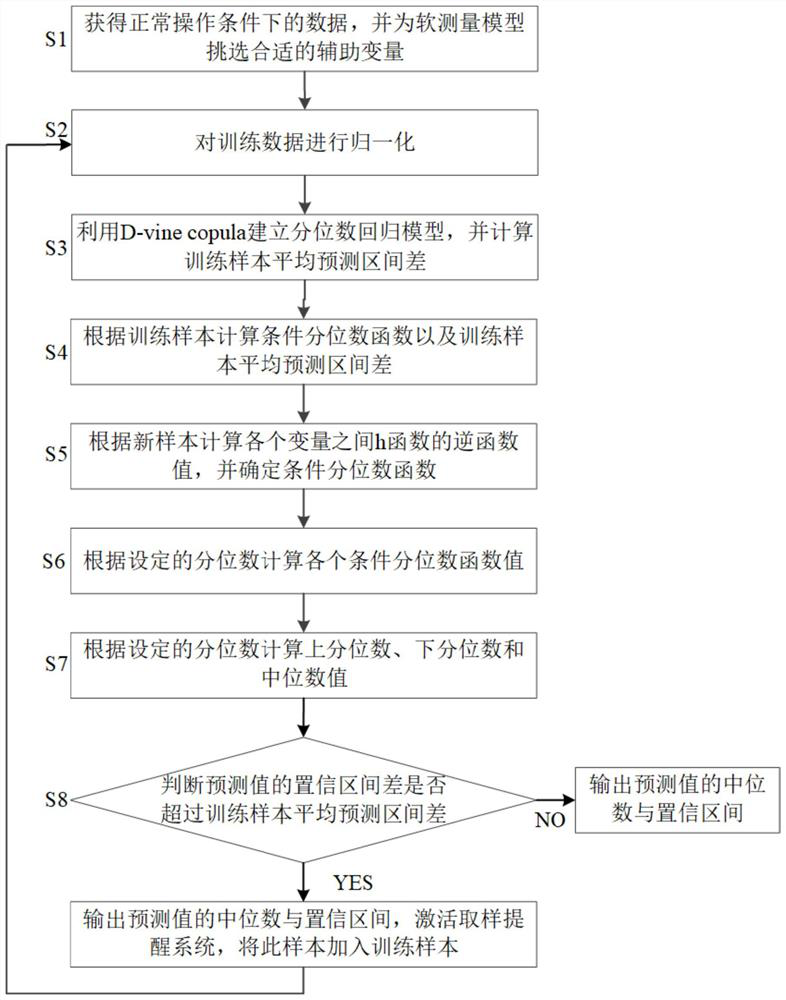

[0134] The present invention discloses an adaptive soft sensor method based on vine copula quantile regression, and the specific steps are as follows:

[0135] [Step S1]: According to actual industrial production conditions and expert knowledge, obtain data under normal operating conditions, and select appropriate auxiliary variables for the soft sensor model;

[0136] [Step S2]: Normalize the training data to obtain data that can be used for copula modeling. Normalize the data see formula (15)

[0137]

[0138] Among them, X i is the variable before transformation, X i ’ is the variable after zero-mean standardization, mean(X i ) is the variable X i mean, sd(X i ) is the variable X i The standard deviation of , m is the dimension of the vector X.

[0139] [Step S3]: Establish a quantile regression model using D-vine copula.

[0140] Step 3.1: Equation (16) constructs the analytical model of D-vine copula:

[0141]

[0142] (F(X j |X j+1 ,...,X j+i-1 ), F(X ...

Embodiment 2

[0184] The description of the following examples will help to understand the present invention, but does not limit the content of the present invention. see figure 2 , this embodiment realizes the prediction of numerical examples, and the data of this implementation example is generated according to formula (25).

[0185] x i ~N(0,1)i=1,2

[0186]

[0187] x 4 =sin(x 2 +1)+x 2 x 3

[0188]

[0189] And add error e~N(0,0.01) on each dimension data. The prediction target is y. A total of 500 sets of data were selected, 400 sets were used to train the copula model, and 100 sets were used for testing.

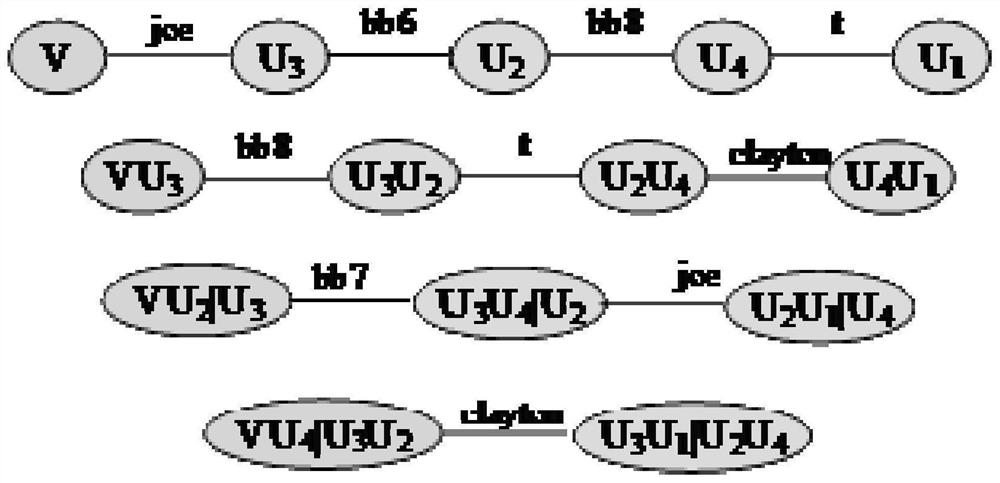

[0190] (1) According to prior information, four auxiliary variables are selected to be x in formula (24) 1 ,x 2 ,x 3 ,x 4 , the key variable is y. (2) Data preprocessing: normalize the zero-mean value of the training samples, and obtain the transformed data as [V, U 1 ,U 2 ,U 3 ,U 4 ]. where V represents the key variable after normalization, U 1 ,U 2 ,U ...

Embodiment 3

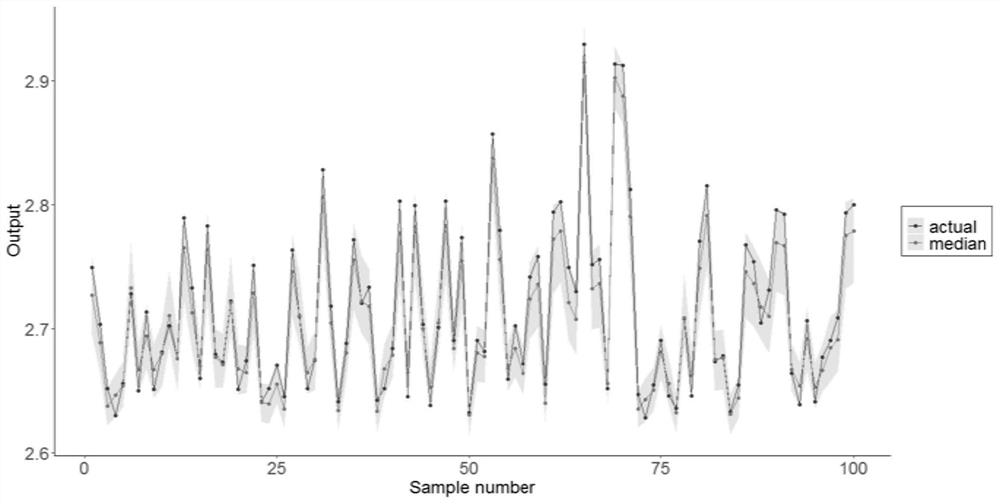

[0203] see Figure 4 , the present embodiment realizes the prediction (PER) of the degree of ethylene cracking in the ethylene cracking process. The data of this implementation example comes from the SRT-III model ethylene cracking furnace, and the prediction target is the cracking rate of ethylene. Ratio) to indicate that 500 sets of data under normal working conditions were selected, 400 sets were used to train the copula model, and 100 sets were used for testing.

[0204] (1) According to the prior information, four auxiliary variables are selected: the average outlet temperature of the cracking furnace x 1 , the density of pyrolysis feedstock x 2 , total feed x 3 and steam hydrocarbon ratio x 4 . The key variable y is the lysis depth indicator PER.

[0205] (2) Data preprocessing: normalize the zero mean value of the training samples to obtain the transformed data [V, U 1 ,U 2 ,U 3 ,U 4 ].

[0206] (3) Using training samples [V, U 1 ,U 2 ,U 3 ,U 4 ] Build the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com