A large-scale wind power generation system using contact electrification technology

A wind power generation system, contact electrification technology, applied in the direction of wind power storage, wind power generation, electrostatic generator/motor, etc., can solve the problems of high cost, complicated maintenance process, low power generation efficiency, etc., to achieve large economy, High power generation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

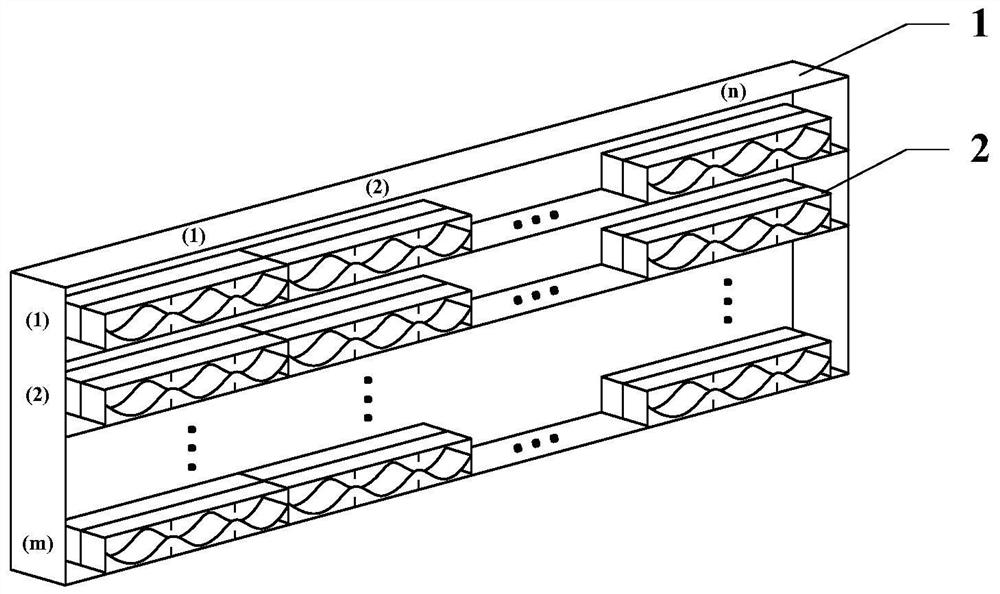

[0029] Referring to Fig. 1, the present embodiment provides a large-scale wind power generation system using contact electrification technology, including several power generation micro-units 2, circuit systems, and chassis 1; the power generation micro-units 2 and the circuit system can be Disassembled and connected to the inside of the chassis 1, the circuit system is electrically connected to the power generation micro-unit 2;

[0030] The power generation microunit 2 includes an upper base 3, an upper electrode 4, a lower electrode 7, and a lower base 8 arranged in sequence from top to bottom; the upper electrode 4 is in contact with the upper base 3, and the lower electrode 7 is connected to the The lower base 8 is contacted and connected; the upper electrode 4, the upper base 3, the lower electrode 7, and the lower base 8 have the same length and are arranged in parallel; It is made of a polymer film that is small and is easy to generate charges during the contact proces...

Embodiment 2

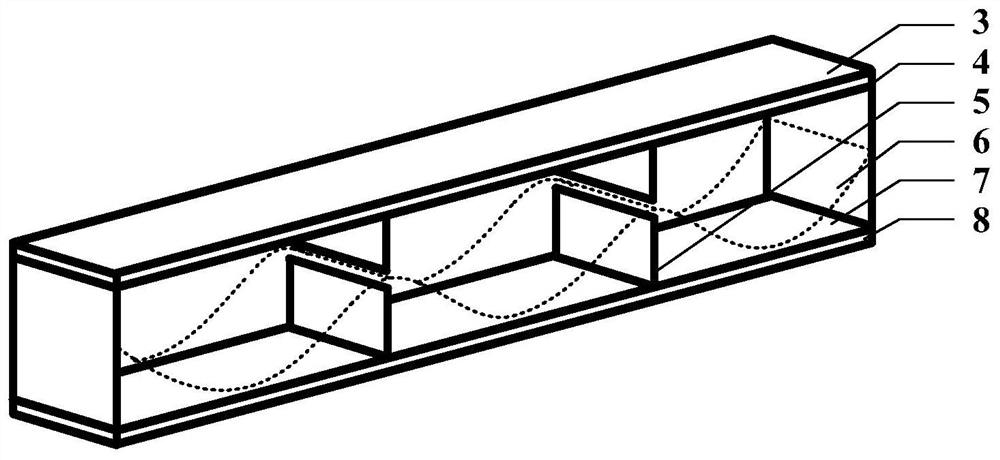

[0043] Referring to Fig. 2, the present embodiment provides a large-scale wind power generation system using contact electrification technology, including several power generation micro-units 2, circuit systems, and chassis 1; the power generation micro-units 2 and the circuit system can be Disassembled and connected to the inside of the chassis 1, the circuit system is electrically connected to the power generation micro-unit 2;

[0044] The power generation microunit 2 includes an upper base 3, an upper electrode 4, a lower electrode 7, and a lower base 8 arranged in sequence from top to bottom; the upper electrode 4 is in contact with the upper base 3, and the lower electrode 7 is connected to the The lower base 8 is contacted and connected; the upper electrode 4, the upper base 3, the lower electrode 7, and the lower base 8 have the same length and are arranged in parallel; the power generation micro-unit 2 also includes a vibrating film layer 6 and an elastic vertical wall...

Embodiment 3

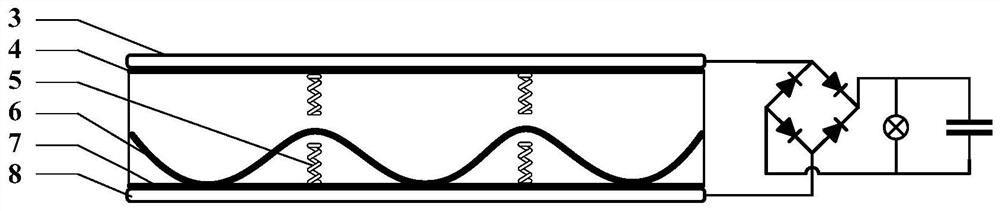

[0057] Referring to Fig. 3, the present embodiment provides a large-scale wind power generation system using contact electrification technology, including several power generation micro-units 2, circuit systems, and chassis 1; the power generation micro-units 2 and the circuit system can be Disassembled and connected to the inside of the chassis 1, the circuit system is electrically connected to the power generation micro-unit 2;

[0058] The power generation microunit 2 includes an upper base 3, an upper electrode 4, a lower electrode 7, and a lower base 8 arranged in sequence from top to bottom; the upper electrode 4 is in contact with the upper base 3, and the lower electrode 7 is connected to the The lower base 8 is contacted and connected; the upper electrode 4, the upper base 3, the lower electrode 7, and the lower base 8 have the same length and are arranged in parallel; the power generation micro-unit 2 also includes a vibrating film layer 6 and an elastic vertical wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com