Mop

A mop and mop rod technology, applied in the field of mop for cleaning, can solve problems such as poor labor-saving effect, poor operating experience, and waste of water squeezing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

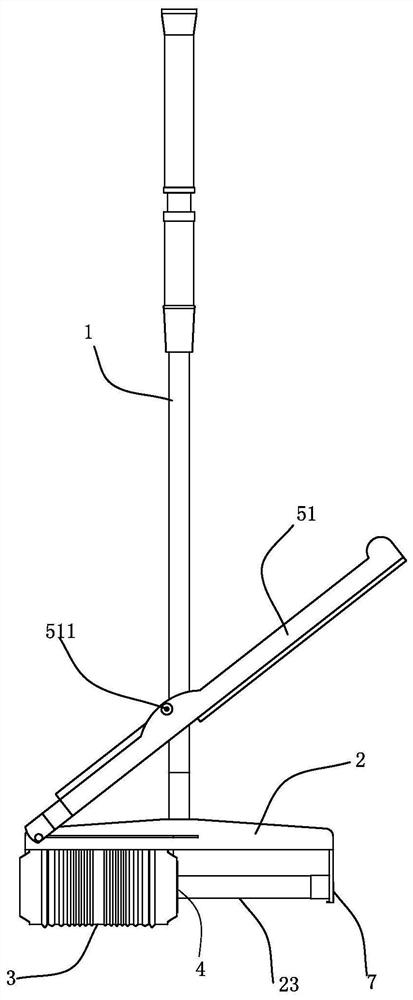

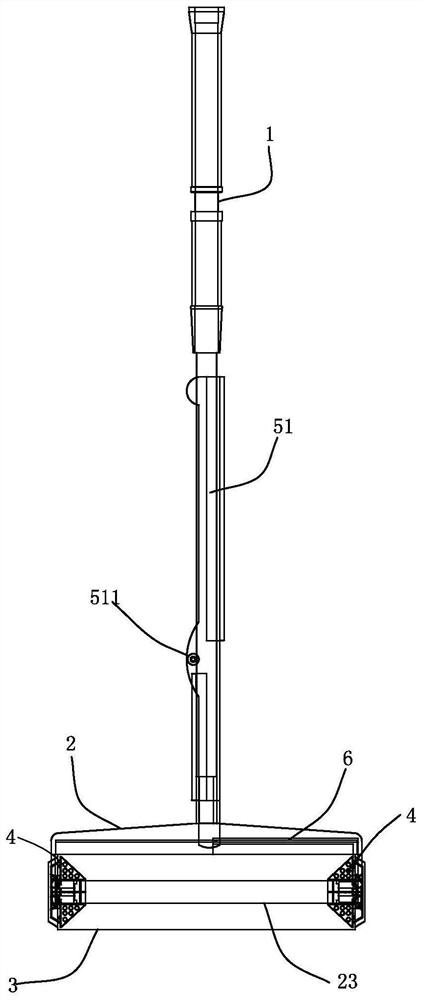

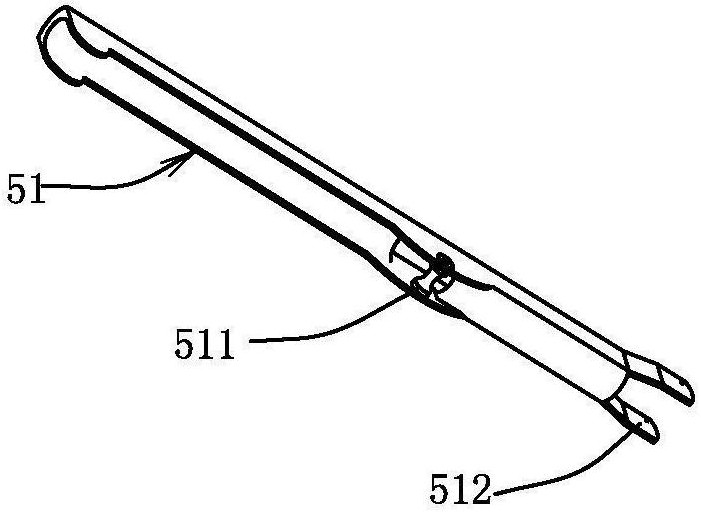

[0057] The present invention relates to a mop, such as Figure 1~2 As shown, it includes a mop rod 1, a mounting frame 2 attached to the lower end of the mop rod, a cleaning piece 3 with at least one end slidable and compressible on the mounting frame 2, and radially deformable cleaning parts located at both ends of the cleaning piece 3. The cover part 4 and the squeeze lever 51 attached to the mop rod 1 and linked with the sliding end of the cleaning part 3 also include an elastic limiting part 7 for limiting the rotation of the cleaning part 3 . The linkage between the water squeezing lever 51 and the cover 4 arranged at the sliding end of the cleaning part 3 is realized through the connecting rod 6, the upper part of the water squeezing lever 51 is exerted force, and the lower part of the water squeezing lever 51 drives the covering of the sliding end of the cleaning part 3 through the connecting rod 6. The piece 4 is squeezed toward the fixed end to realize the compression...

Embodiment 2

[0070] The specific embodiment 2 is basically the same as the embodiment 1, the difference is that the traction rib 43 is an arc-shaped plate made of rigid material conforming to the rotation direction of the installation shaft.

[0071] Such as Figure 14 As shown, the thickness near the root of the traction rib 43 connected with the sliding part 41 is thinner than other positions, which is easy to deform in the direction of rotation, and the flexible cover plate 42 and the rigid traction rib 43 tend to deform in the direction of rotation when they are compressed. .

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 1, except that the cover plate 42 is provided with directional deformation components 422 protruding toward the inner end of the sliding part 41 at intervals along the circumferential direction.

[0074] Such as Figure 15 As shown, the sliding part 41 is provided with a directional deformation assembly 422 protruding toward the inner end of the sliding part 41 along the circumferential distance, and the directional deformation assembly 422 forms an included angle with the outer wall of the sliding part 41, and between the two Connected by the traction ribs 43, the beneficial effect is to reduce the radially inward pulling degree of the traction ribs 43 to the edge of the end portion of the cleaning element 3 when water is squeezed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com