Composite mop head

A mop head and mop rod technology, applied in the field of composite mop heads, can solve the problems of poor adsorption capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

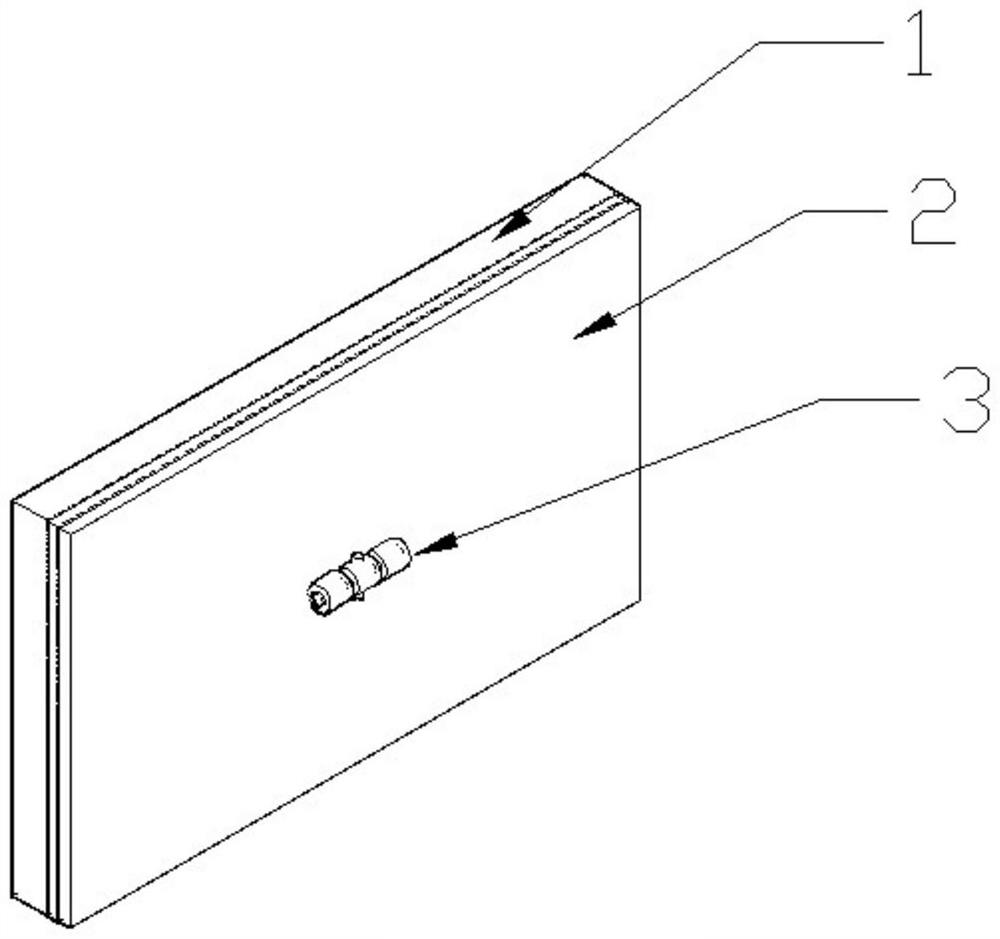

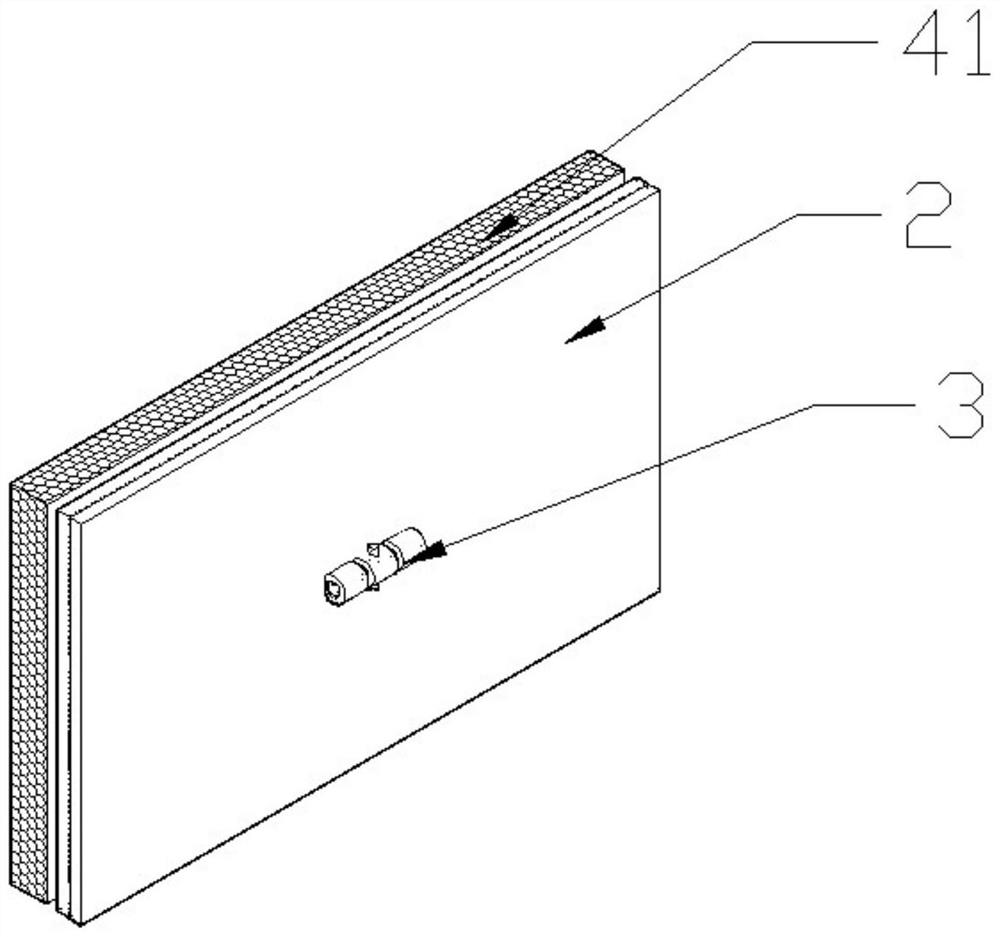

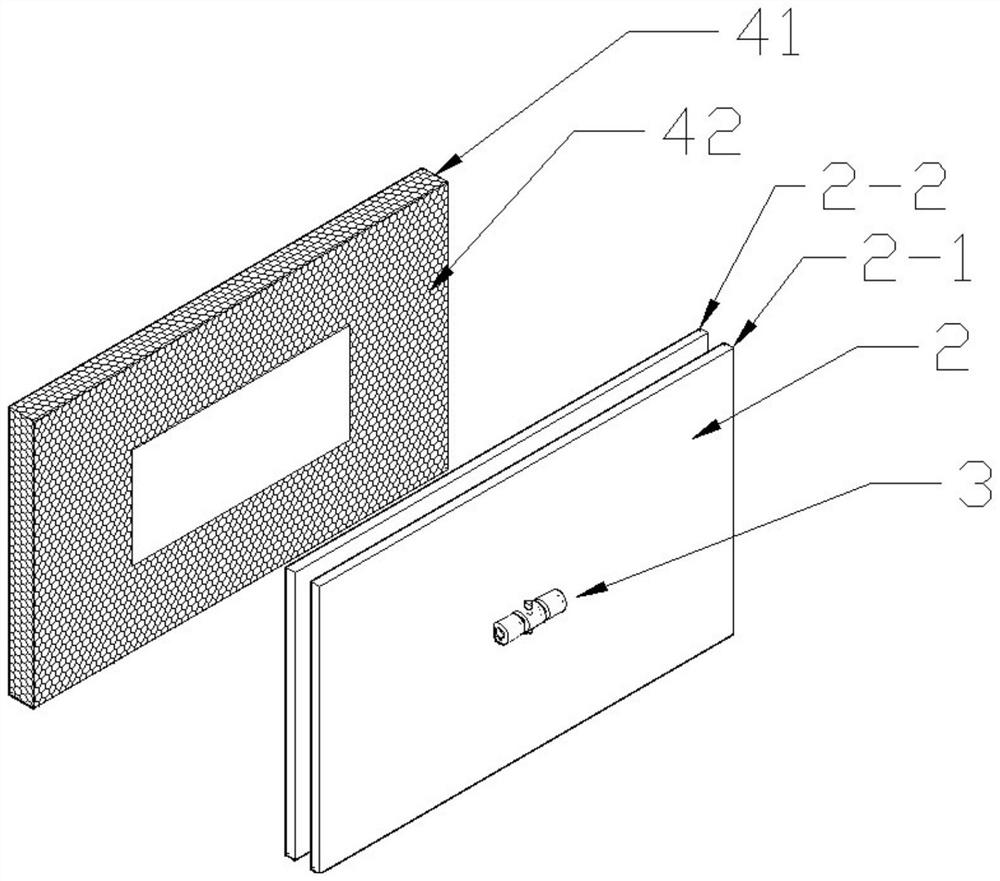

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a composite mop head is mainly composed of a collodion layer 1, a hard board layer 2, and a mop rod connector 3. The collodion layer 1 is covered with a fabric wiping layer 4, and the wiping layer 4 is close to the collodion layer 1. The wiping layer and the collodion layer are combined and integrally connected on the hard board layer 2 .

[0023] The wiping layer 4 is a mesh fabric layer that is permeable but not water-holding, and the diameter of the circumscribed circle of the mesh is 0.5mm≤Ф≤15mm. The mesh fabric layer is made of water-resistant, abrasion-resistant material. The mesh fabric layer is covered outside the collodion layer 1, and is divided into a front 43, a side 41, and a back 42. The back has an opening socketed on the back of the collodion layer 1. Collodion layer 1 selects the elastic sponge body that can absorb water, squeeze water for use.

[0024] The hard board laye...

Embodiment 2

[0026] Such as Image 6 As shown, the mesh fabric layer is bonded on the back of the collodion layer; the diameter of the circumscribed circle of the mesh is 1mm≤Ф≤8mm. The front 43 of the mesh fabric layer in contact with the ground adopts jacquard weaving, which has a three-dimensional effect, and several fibers are interwoven in the mesh. All the other structures are with embodiment 1.

Embodiment 3

[0028] Such as Figure 7 As shown, the hard board layer 2 is composed of two hard boards that can be folded in half, and the rest of the structure is the same as that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com