Manufacturing method of composite core shaft for lightweight spherical hinge and lightweight spherical hinge

A technology of composite mandrel and manufacturing method, which is applied to shafts, pivots, shafts and bearings, etc., can solve the problems of large cutting amount and low material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

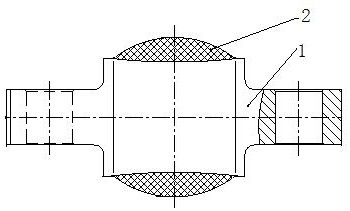

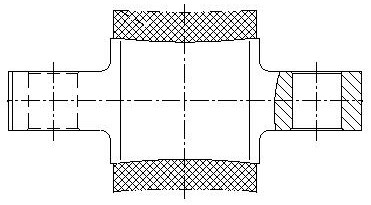

[0045]A method for manufacturing a composite mandrel for a lightweight spherical hinge. The composite mandrel for a lightweight spherical hinge includes a metal mandrel 1 and a winding section 2 solidified on the middle section of the metal mandrel 1. The outer wall of the winding section 2 is from two ends to A convex spherical surface with gradually increasing middle diameter, characterized in that the manufacturing steps are as follows:

[0046] S1: Design the weight ratio of the metal mandrel 1 and the winding section 2 according to the lightweight requirements of the lightweight spherical hinge, and design the size of the metal mandrel 1 and the winding section 2 according to the weight and size requirements of the lightweight spherical hinge;

[0047] S2: Manufacture the metal mandrel 1, and process a positioning structure for axially positioning the winding section 2 in the middle section of the metal mandrel 1;

[0048] S3: Winding the resin-impregnated glass fiber to ...

Embodiment 2

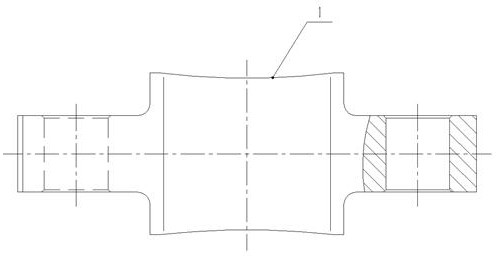

[0059] The difference from Embodiment 1 is that "processing a positioning structure for axially positioning the winding section 2 in the middle section of the metal mandrel 1" in step S2 refers to dividing the middle section of the metal mandrel 1 into The straight section 11 at the end, the raised section 12 between the two straight sections 11 and the positioning section 13 between the straight section 11 and the raised section 12, the straight section 11 is straight, and the raised section 12 is From both ends to the middle, the diameter gradually increases and the surface is smooth. The positioning section 13 is an inner concave ring groove with a diameter smaller than the straight section 11 and the convex section 12. The winding section 2 is positioned axially by the positioning section 12. A concave annular groove-shaped positioning section 13 is processed in the middle section of the metal mandrel, and the winding section 2 is axially positioned through the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com